Multifunctional Aluminum Foil Packaging Machine

A multi-functional, packaging machine technology, applied in packaging machines, packaging, transportation and packaging, etc., can solve the problems of uneven aluminum foil sub-rolls, inaccurate operation positioning, poor adhesion of aluminum foil, etc., to achieve smooth surface and operation positioning The effect of high precision and high fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

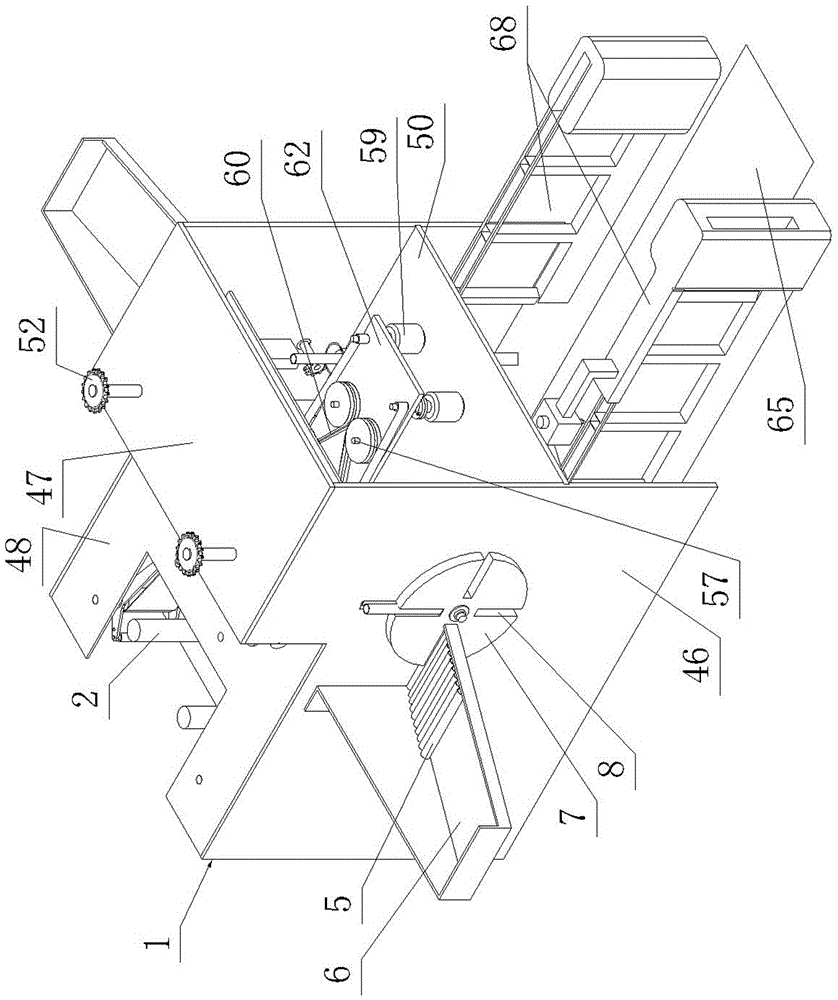

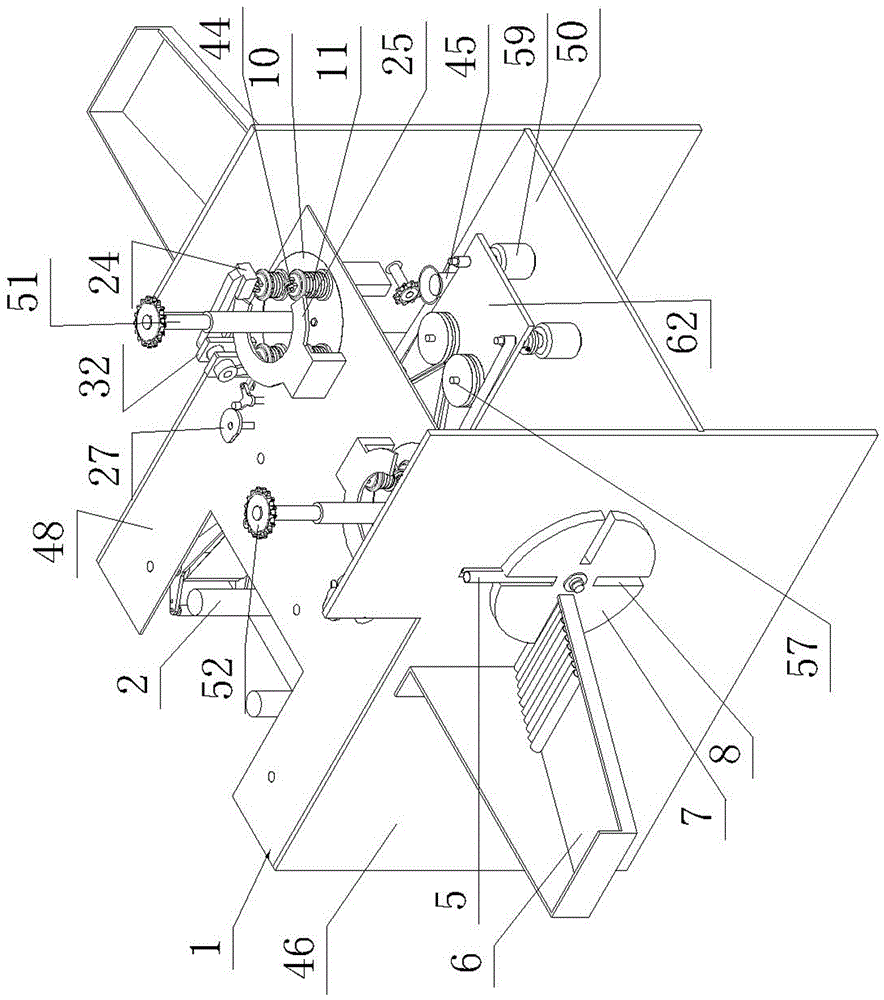

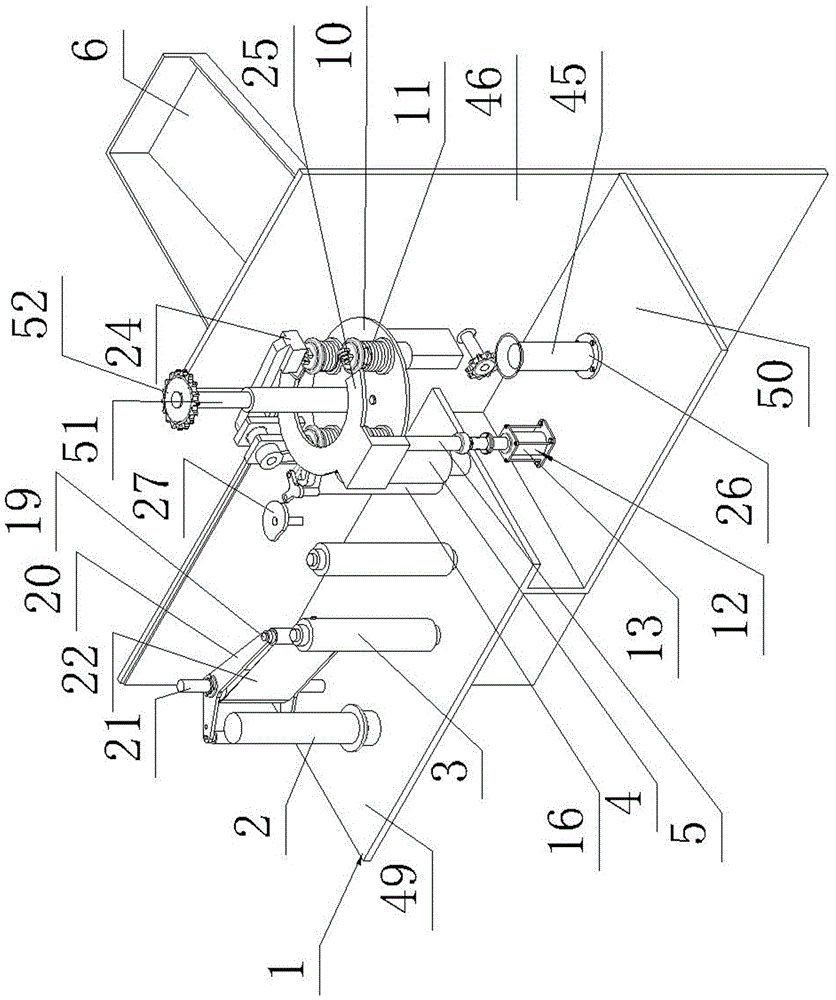

[0035] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 As shown, the multifunctional aluminum foil packaging machine of the present invention includes a frame 1, and the frame includes two side plates 46, a top plate 47, an upper support plate 48, a middle support plate 49 and a lower support plate 50, the top plate 47 and three Both ends of a support plate are fixed with two side plates 46 respectively.

[0036] This multifunctional aluminum foil packaging machine also includes a feed channel 6 fixed on the side plate 46 of the frame 1 for shelving a plurality of side-by-side paper tubes 5, a rotatably fitted on the side plate 46 of the frame 1 and Feed carousel 7 driven by electric motor. The feed channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com