A bending line mechanism

A technology of bending line and bending device, which is applied in assembly machines, lighting and heating equipment, sorting and other directions, can solve the problem of no bending pin pipelines, etc., achieve simple structure and function implementation, and reduce floor space. , the effect of improving the efficiency of production operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

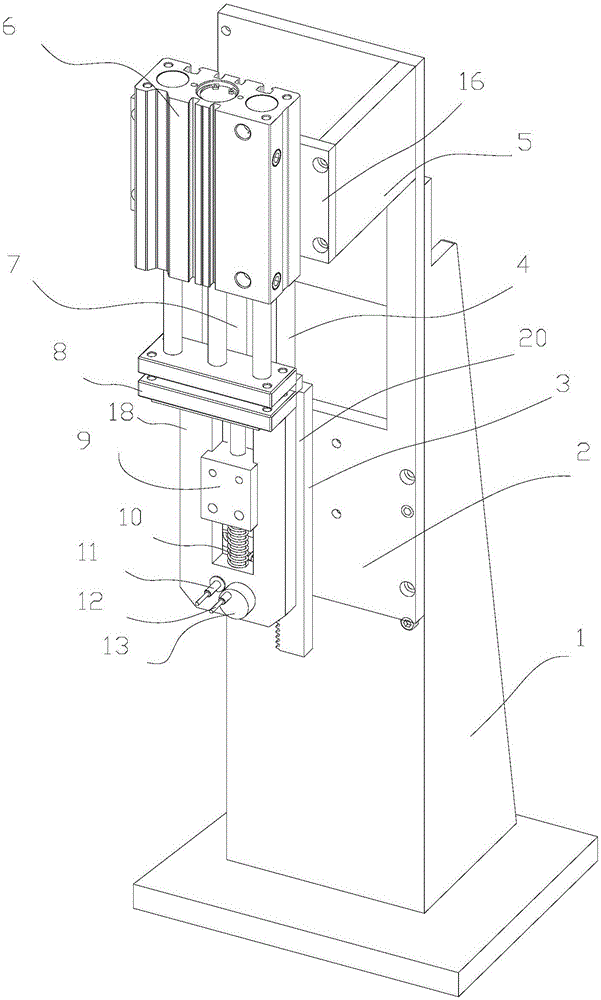

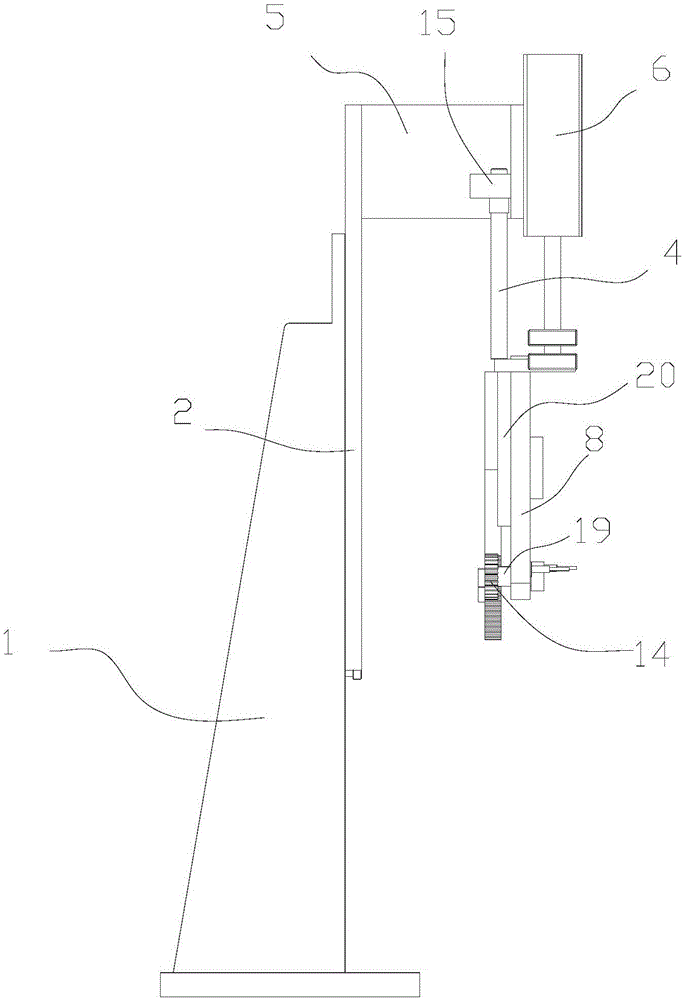

[0047] see figure 1 , is an embodiment of the bending line mechanism of the present invention, which includes: a support platform 1, a cantilever group (which includes: a fixed panel 2, an arm plate 5, and a mounting plate 16), a cylinder 6, an adjustment frame 15, a total pull rod 7, a bearing Plate 8, pressing down pull bar 4, lower pressing plate 18, connecting plate 20, guide rod 17, spring, slide block 9 and bending line device (it comprises: gear 14, rack 3, axle 13, axle sleeve 19, bending needle 11, threading needle 12), wherein:

[0048] The chassis of the support platform 1 is placed horizontally; it is used for fixing and installing the cantilever group.

[0049] The cantilever group includes: fixed panel 2, arm plate 5 and mounting plate 16; one end of the cantilever group is fixed on the support platform 1, and the other end is suspended in the air; specifically: the fixed panel 2 of the cantilever group is fixed on the support platform 1 with screws, and the arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com