Device and method for preparing ethylene from ethane oxidative dehydrogenation

A technology for oxidative dehydrogenation and ethane, applied in chemical instruments and methods, organic chemistry, hydrocarbons, etc., can solve problems such as the inability to adjust gas components, achieve good universality, extend service life, and expand applications effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] like figure 1 As shown in the device for producing ethylene by oxidative dehydrogenation of ethane, the inner diameter of the main reaction tube 1 is 12 mm, the length is 50 cm, and the inside is circular; the first branch pipe 4, the second branch pipe 5, the third branch pipe 6 and the fourth branch pipe 7 Four connection points with the main pipeline divide the catalyst bed 25 into five equal parts; wherein the inert gas source 10 provides 2 A mixture of 9.8% He gas and 90.2% He gas.

[0042] The method for producing ethylene by oxidative dehydrogenation of ethane, adopts the above-mentioned device for producing ethylene by oxidative dehydrogenation of ethane, comprising the following steps:

[0043] Step 1, filling the catalyst; the specific method is:

[0044] The catalyst is a mixture, and the first part is a Ni catalyst supported by Y-type molecular sieve. The specific preparation method can be found in the literature [X.Lin, et al., Journal of Catalysis265(200...

Embodiment 2

[0055] The difference from Example 1 is:

[0056] Step 2. Control F(O 2 ) 0 =7.1mL·min -1 , then F(O 2 ) 0 / F(C 2 h 6 ) 0 is 0.70;

[0057] Step three, the oxygen flow rate in four branch pipes are respectively: F(O 2 ) 0,i =0.6mL·min -1 , F(O 2 ) 0,ii =0.6mL·min -1 , F(O 2 ) 0,iii =0.4mL·min -1 and F(O 2 ) 0,iv =0.4mL·min -1 .

[0058] When the gas flow rate of all pipelines and the temperature of the catalyst bed 25 reach the set value, the device is adjusted and starts continuous production.

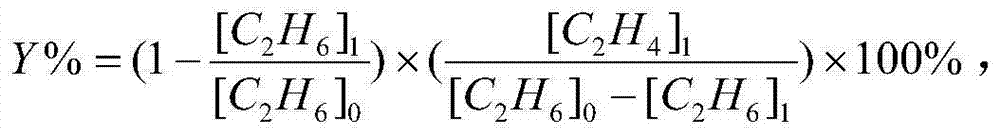

[0059] In order to verify the effect of this embodiment, this example uses a gas chromatograph to quantitatively analyze the composition of the product gas 14 of the above-mentioned step 2 and the product gas 14 of the step 3; the ethylene yield Y of the step 2 is calculated 1 %=14.3%, the ethylene yield Y of step three 2 %=23.1%; the latter is 8.8% higher than the former.

[0060] The contrast of this example and embodiment one also can find out, under the situ...

Embodiment 3

[0062] The difference from Example 1 is:

[0063] Step 1, the catalyst composition is changed from Ni / Y in example 1 to Ni(NO 3 ) 2 Ni / Al Prepared by Solution Impregnation 2 o 3 catalyst.

[0064] When the gas flow rate of all pipelines and the temperature of the catalyst bed 25 reach the set value, the device is adjusted and starts continuous production.

[0065] In order to verify the effect of this embodiment, this example uses a gas chromatograph to quantitatively analyze the composition of the product gas 14 of the above-mentioned step 2 and the product gas 14 of the step 3; the ethylene yield Y of the step 2 is calculated 1 %=10.6%, the ethylene yield Y of step three 2 %=15.1%; the latter is 4.5% higher than the former.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com