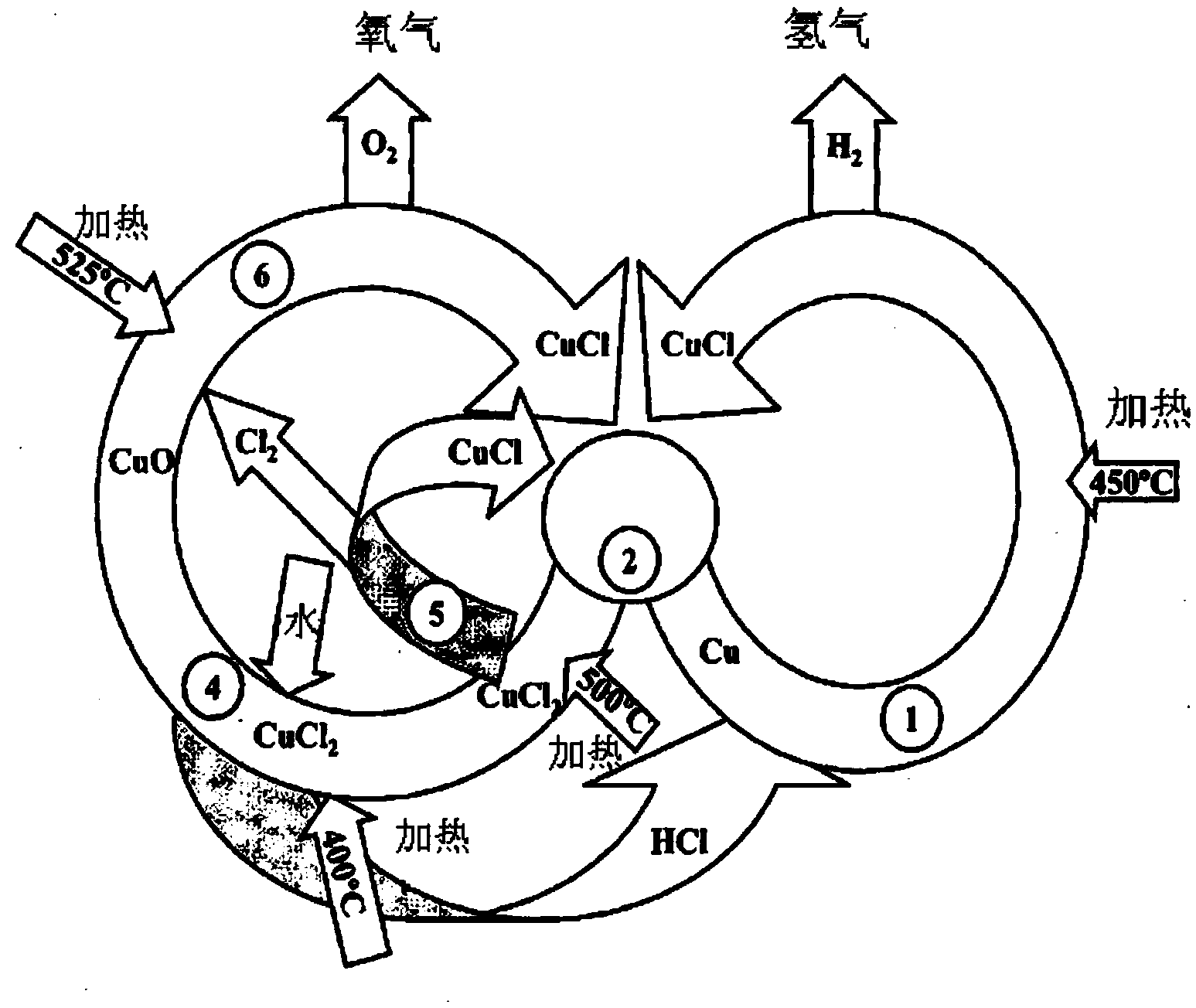

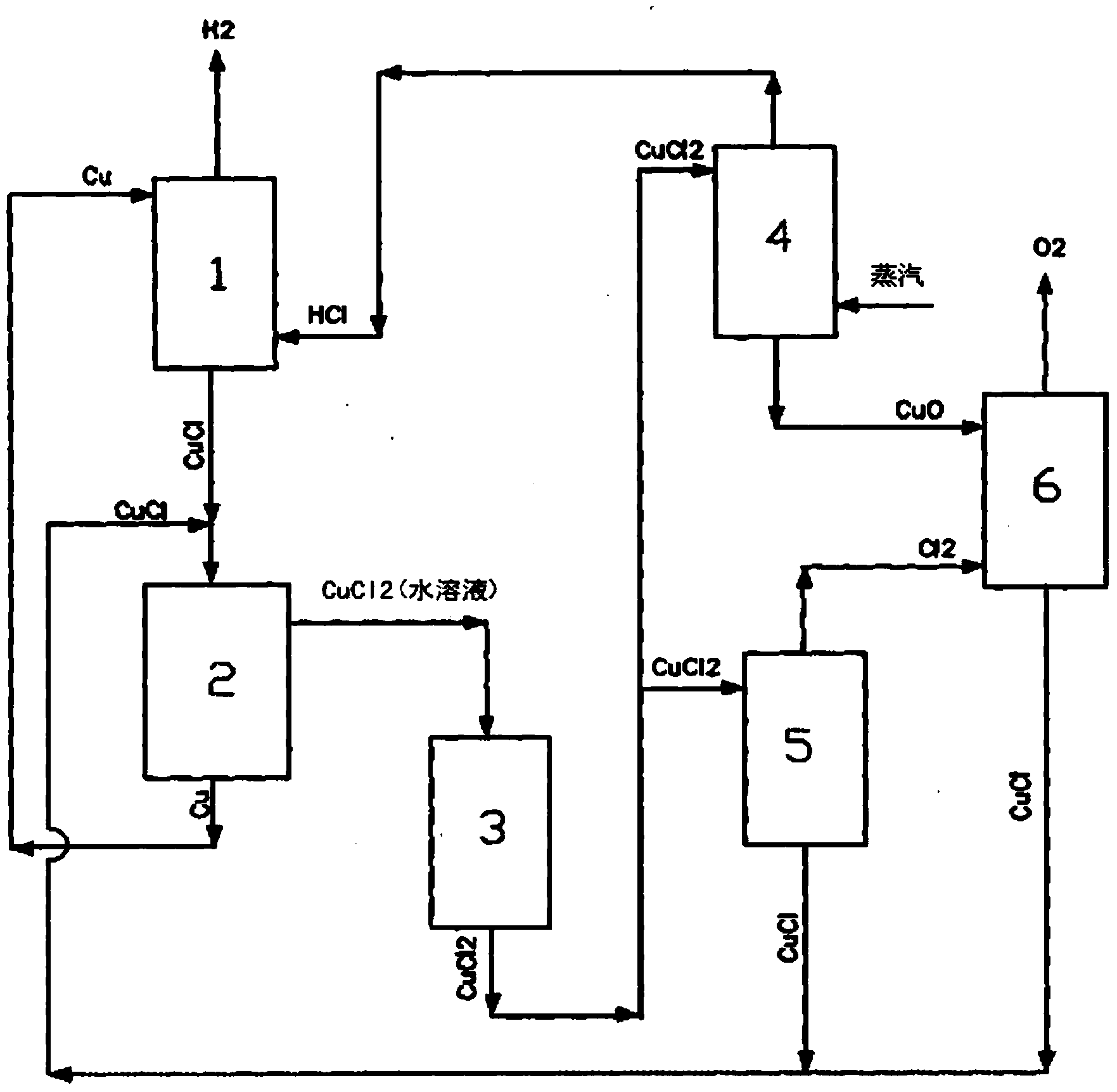

Hydrogen production method by multi-step copper-chlorine thermochemical cycle

一种热化学、氯化氢的技术,应用在化学仪器和方法、氢/合成气生产、氢的生产等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

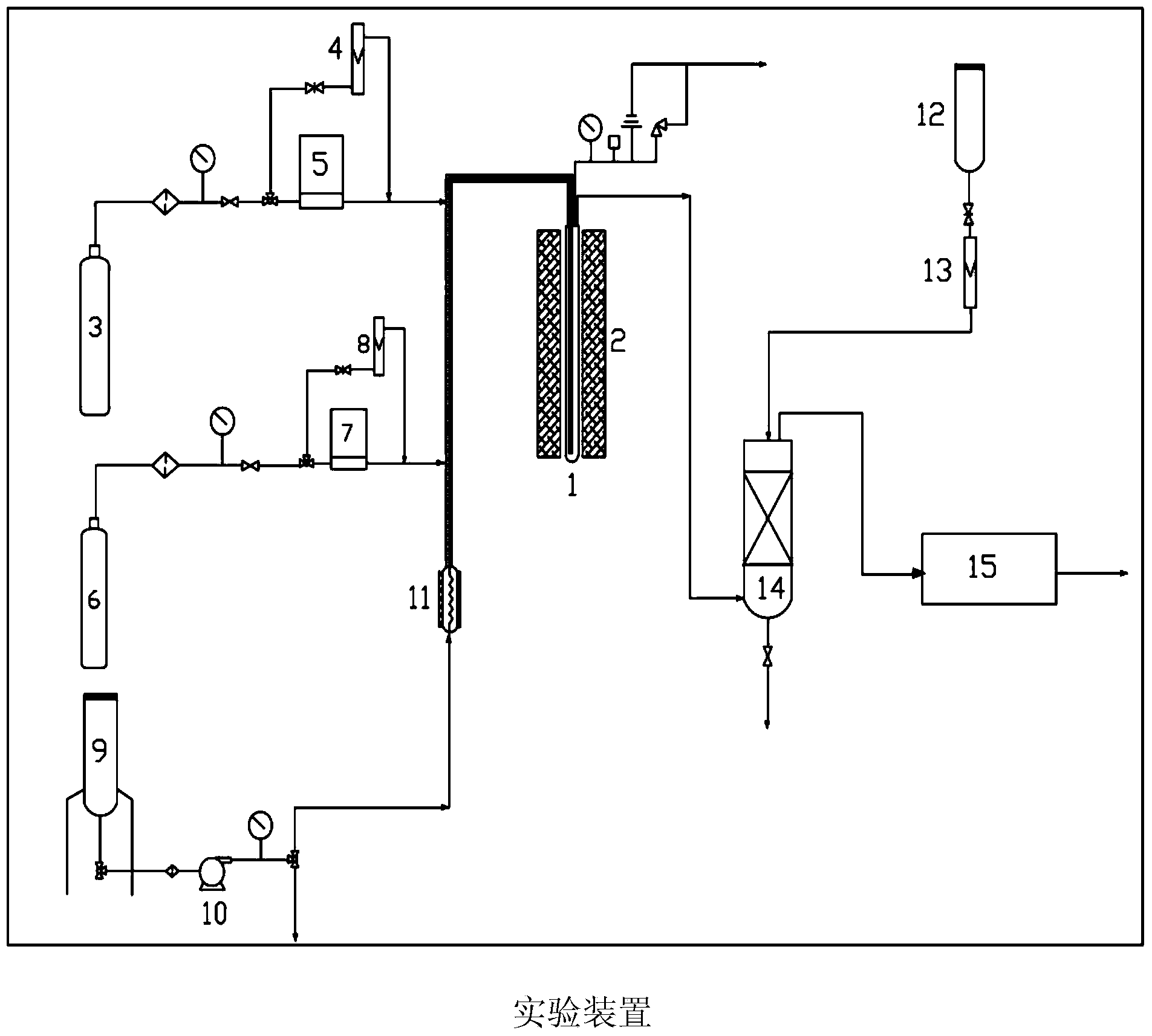

[0127] According to the above disclosure of the present invention, the following experiments were carried out in a quartz microreactor. The reaction was carried out as a fixed bed reactor type. The dry hydrogen chloride gas required for the reaction was supplied into the reactor through a mass flow controller through a quartz tube extending to the bottom of the reactor. The reaction is carried out under atmospheric pressure. Dry hydrogen chloride gas is introduced into the reactor at the desired flow rate. The results are shown in Table 1. The reaction is carried out under the following operating conditions:

[0128] Copper (Cu): 0.015 mol (1 gram)

[0129] Molar ratio of HCl / Cu: 5:1

[0130] Copper (Cu) size: 3-5μm

[0131] N 2 Flow rate: 15cm 3 / minute

[0132] Table 1

[0133] Example number

Embodiment 6-8

[0135] According to the above disclosure of the present invention, the following experiments were carried out in a quartz microreactor. The reaction was carried out as a fixed bed reactor type. The dry hydrogen chloride gas required for the reaction was supplied into the reactor through a mass flow controller through a quartz tube extending to the bottom of the reactor. The reaction is carried out under atmospheric pressure. Dry hydrogen chloride gas is introduced into the reactor at the desired flow rate. The results are shown in Table 2. The reaction is carried out under the following operating conditions:

[0136] Copper (Cu): 0.015 mol (1 gram)

[0137] Molar ratio of HCl / Cu: 1:1

[0138] Copper (Cu) size: 3-5μm

[0139] Temperature: 450°C

[0140] Table 2

[0141] Example number

Embodiment 9-11

[0143] According to the above disclosure of the present invention, the following experiments were carried out in a quartz microreactor. The reaction was carried out as a fixed bed reactor type. The dry hydrogen chloride gas required for the reaction was supplied into the reactor through a mass flow controller through a quartz tube extending to the bottom of the reactor. The reaction is carried out under atmospheric pressure. Dry hydrogen chloride gas is introduced into the reactor at the desired flow rate. The results are shown in Table 3. The reaction is carried out under the following operating conditions:

[0144] Copper (Cu): 0.015 mol (1 gram)

[0145] Copper (Cu) size: 3-5μm

[0146] Temperature: 450°C

[0147] N 2 Flow rate: 50cm 3 / minute

[0148] table 3

[0149] Example number

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com