A vertical hybrid magnetic levitation flywheel energy storage system

A flywheel energy storage and magnetic levitation technology, which is applied in the direction of controlling mechanical energy, bearings, electrical components, etc., can solve the problems of difficulty in increasing the motor speed, low space utilization rate, and low energy storage density of the system, achieving high edge line speed and system The effect of strong rotor stability and large energy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. The specific embodiments described herein are only used to explain the present invention, and are not intended to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as they do not conflict with each other.

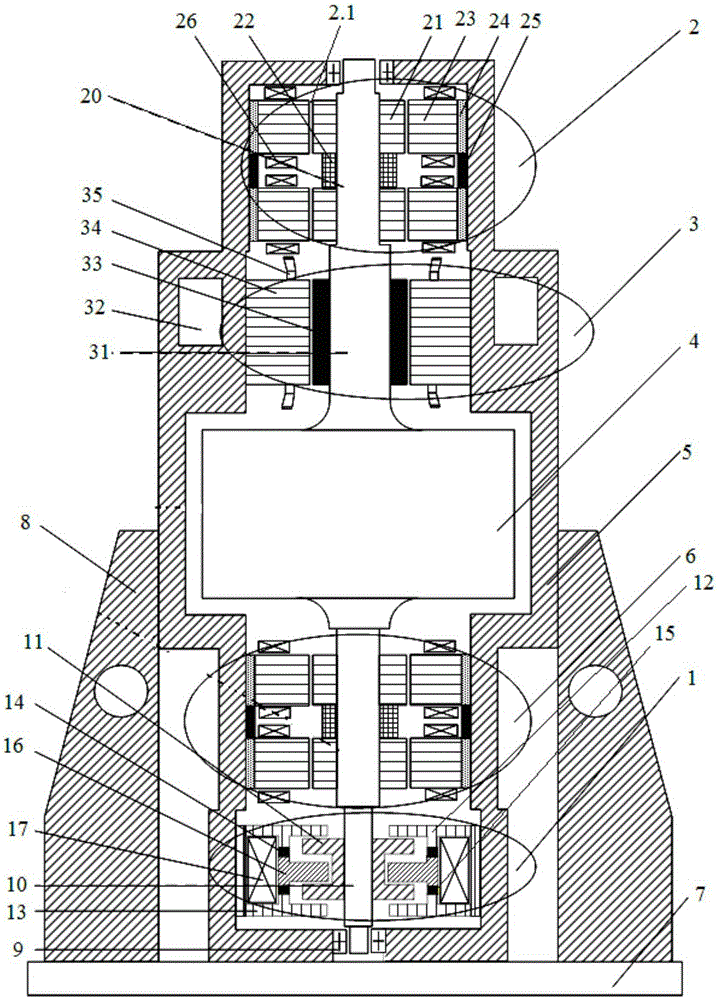

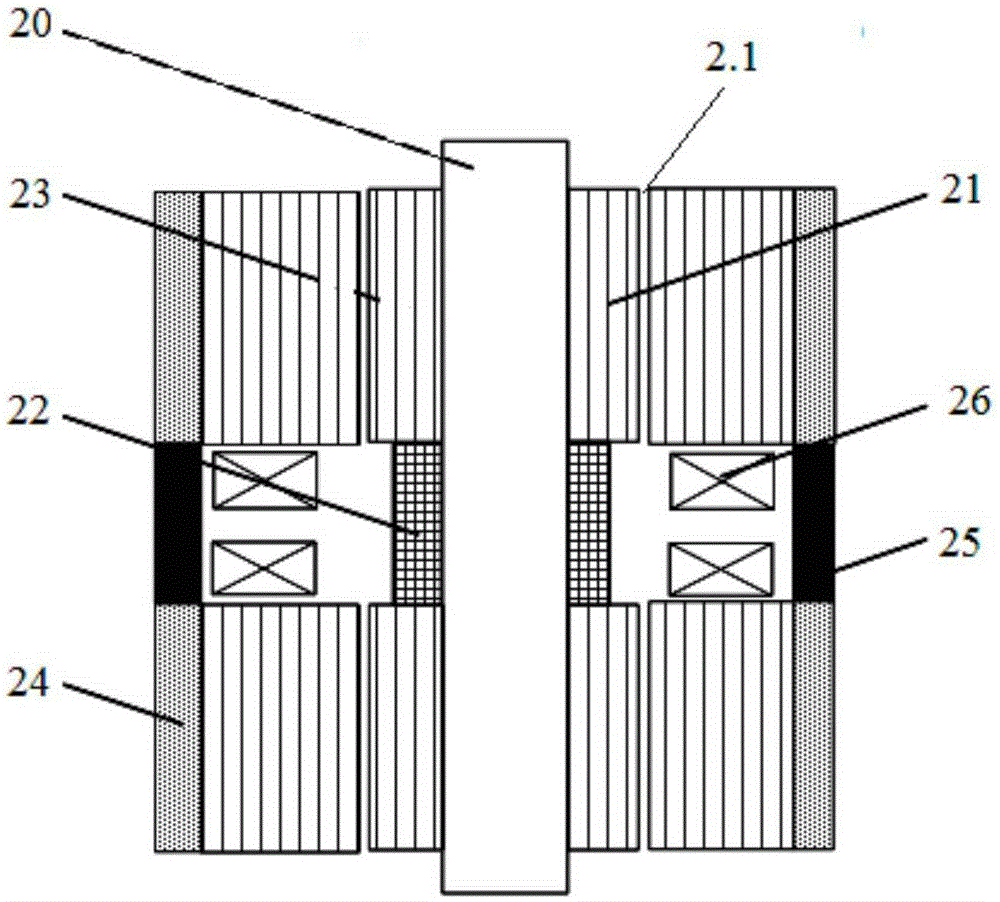

[0038] like figure 1 Shown is a vertical hybrid magnetic suspension flywheel energy storage system, including a metal shell 5, a base 7, and an upper radial hybrid magnetic bearing 2, a high-speed permanent magnet motor 3, a flywheel arranged in the metal shell 5 sequentially from top to bottom The main body 4, the lower radial hybrid magnetic bearing 6 and the axial hybrid magnetic bearing 1, and the upper radial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com