Automobile generator rotor framework

A technology for automobile generators and rotor skeletons, applied to the rotating parts of the magnetic circuit, the shape/style/structure of the magnetic circuit, etc., can solve the problem that the insulating liquid cannot fully penetrate the copper wire, there is no fixing effect, and the generator does not generate electricity and other problems, to achieve the effect of avoiding copper wire breakage, eliminating no power generation, and preventing copper wire breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

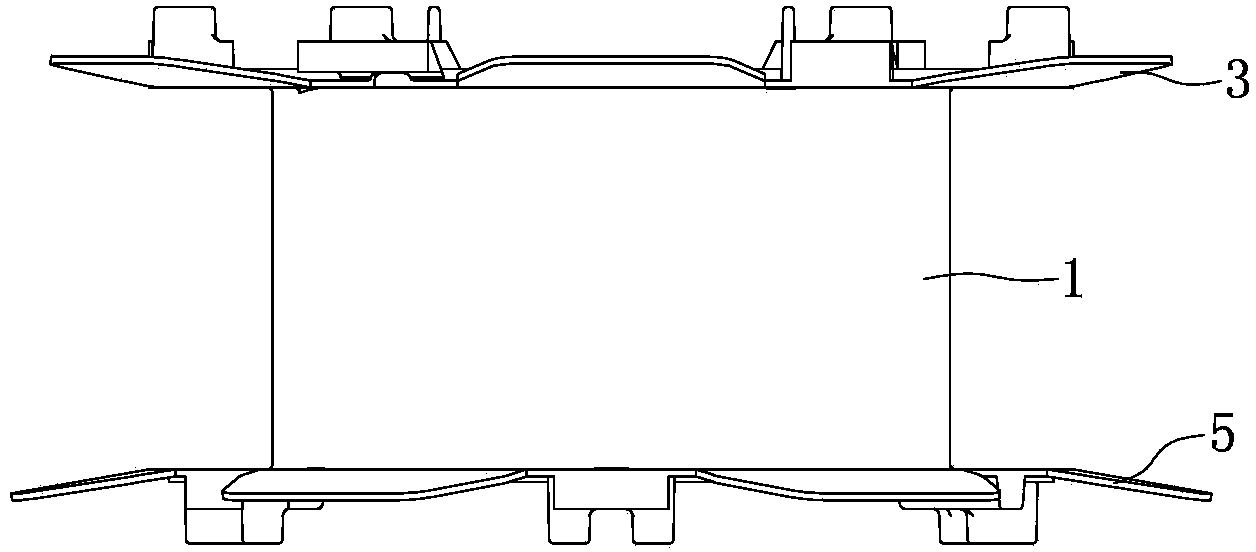

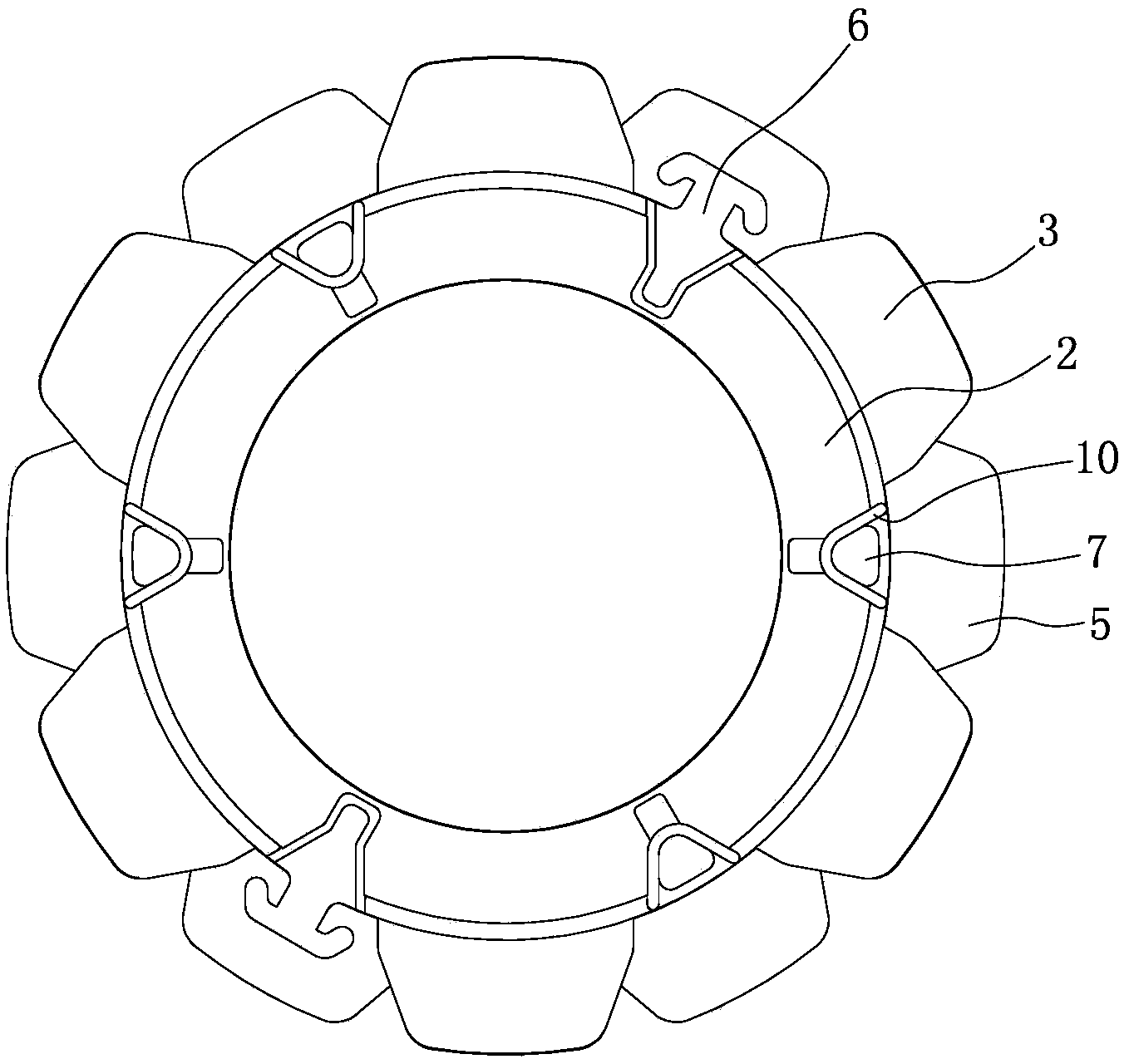

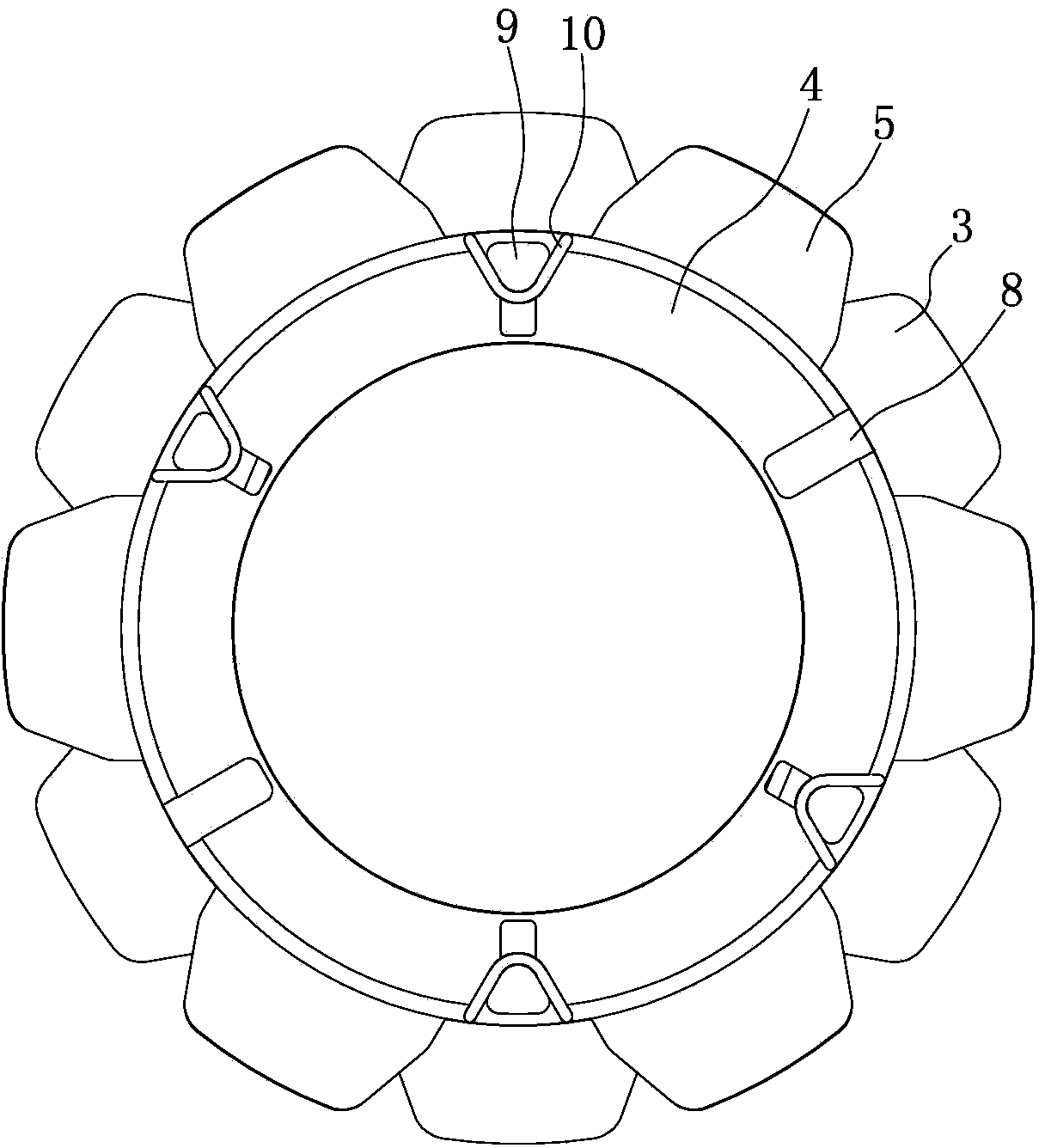

[0016] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the cylinder body 1 is a short straight cylindrical structure with both ends open, and one end of the cylinder body 1 is integrally formed with a first baffle plate 2, and two winding parts 6 are integrally formed on the first baffle plate 2, and The periphery of the first baffle 2 is distributed with a plurality of first fan blades 3 uniformly distributed on the circumference, and the first fan blades 3 are integrated with the first baffle 2 . The other end of the barrel 1 is integrally formed with a second baffle plate 4, and a plurality of second fan blades 5 evenly distributed on the circumference are distributed on the periphery of the second baffle plate 4. The second fan blades 5 and the second baffle plate 4 are An integral structure, and the second fan blade 5 is misaligned wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com