A real-time learning soft-sensing modeling method for a butanizer based on a Gaussian mixture model

A Gaussian mixture model and modeling method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of reduced model prediction accuracy, insufficient consideration of the characteristics of new samples, and influence on the selection of similar samples. To achieve the effect of improving the prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

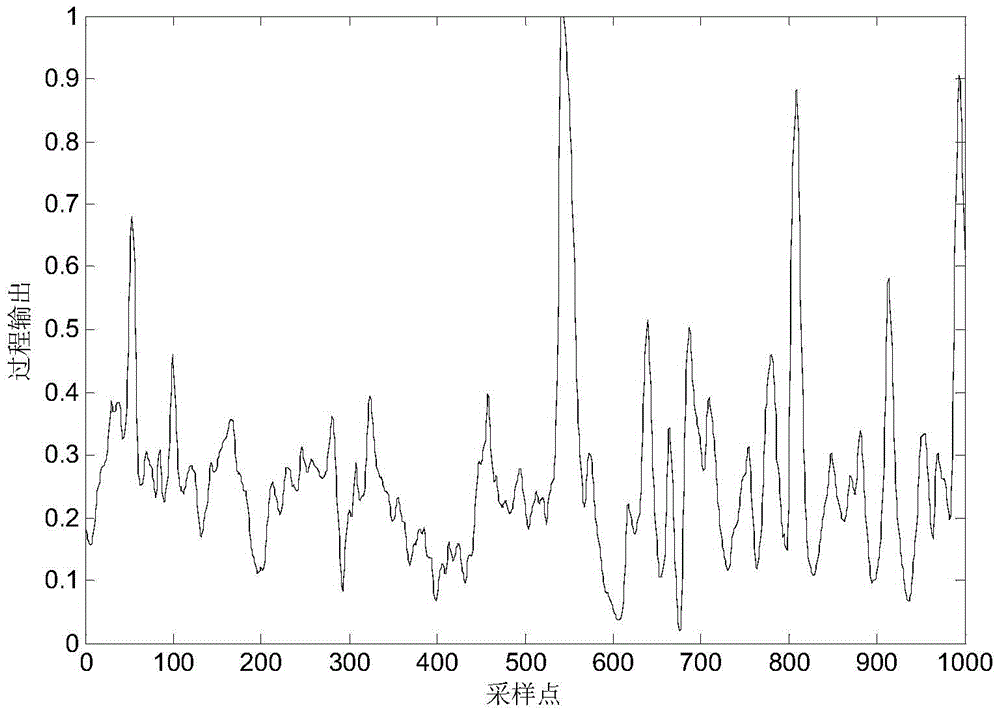

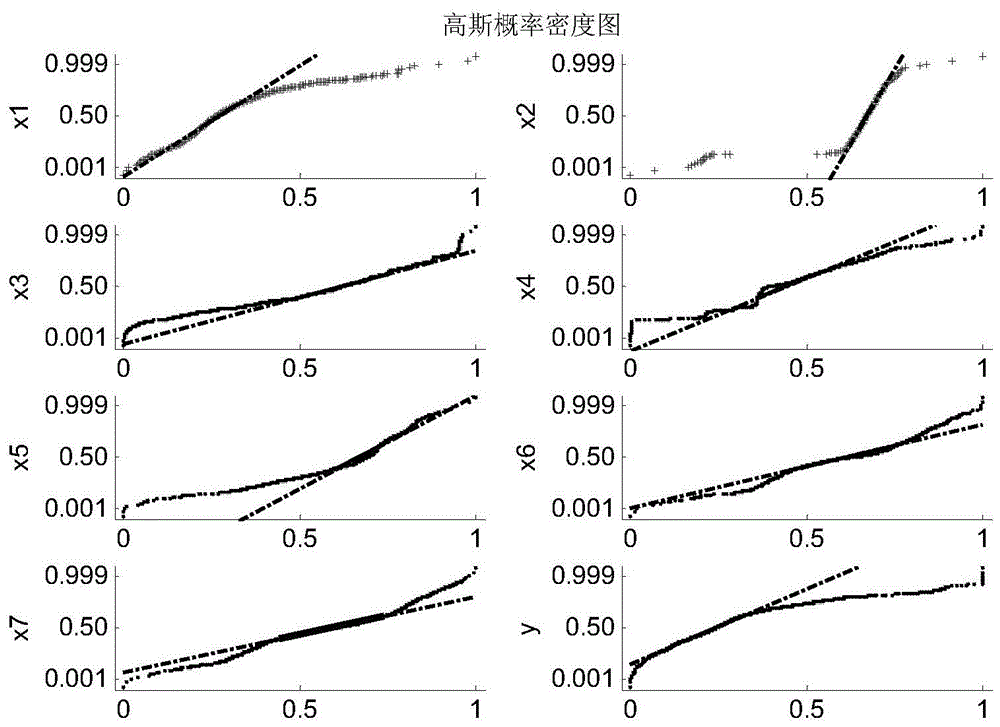

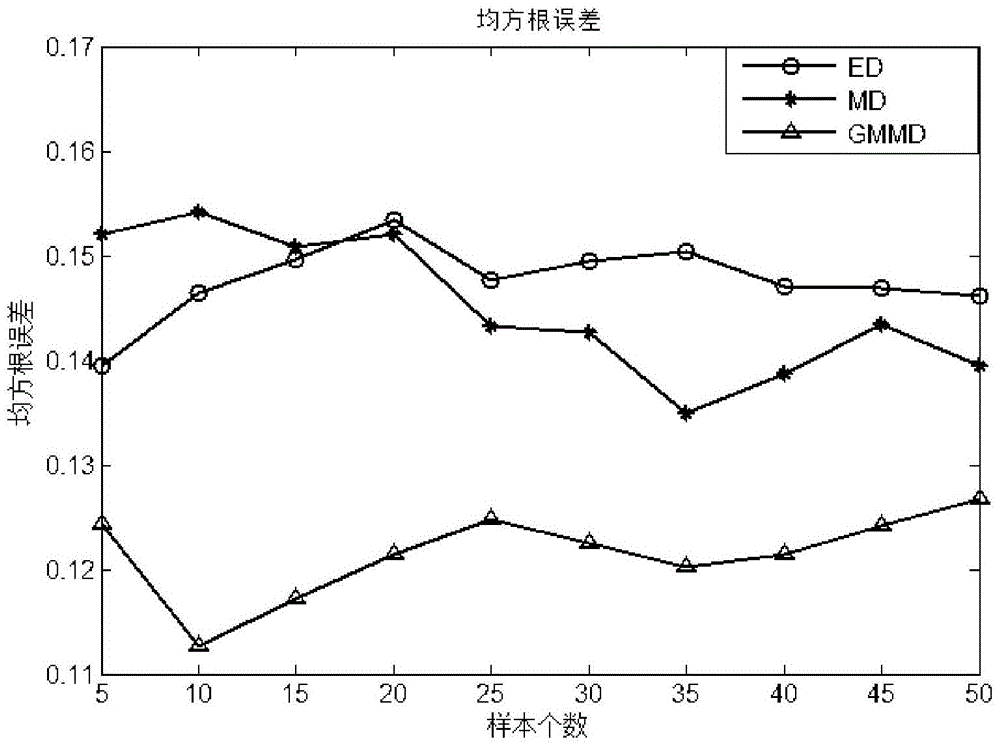

[0027] The invention aims at the soft sensor modeling problem of the non-Gaussian nonlinear industrial process. Firstly, the process Gaussian mixture model is trained, the parameters of each Gaussian component are obtained, corresponding sub-models are established, and all model parameters are stored in a database for future use. Then, the Bayesian method is used to calculate the posterior probability that the sample to be predicted belongs to each Gaussian component, and the local Mahalanobis distance under each Gaussian component, so as to obtain the weighted sample similarity definition index, and it is more reasonable to select similar samples for local modeling. Compared with other current methods, the present invention can not only handle the non-Gaussian and non-linear properties well, but also fully extract the characteristics of samples to be predicted, and more reasonably select similar samples for real-time learning and model building, which is beneficial to improve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com