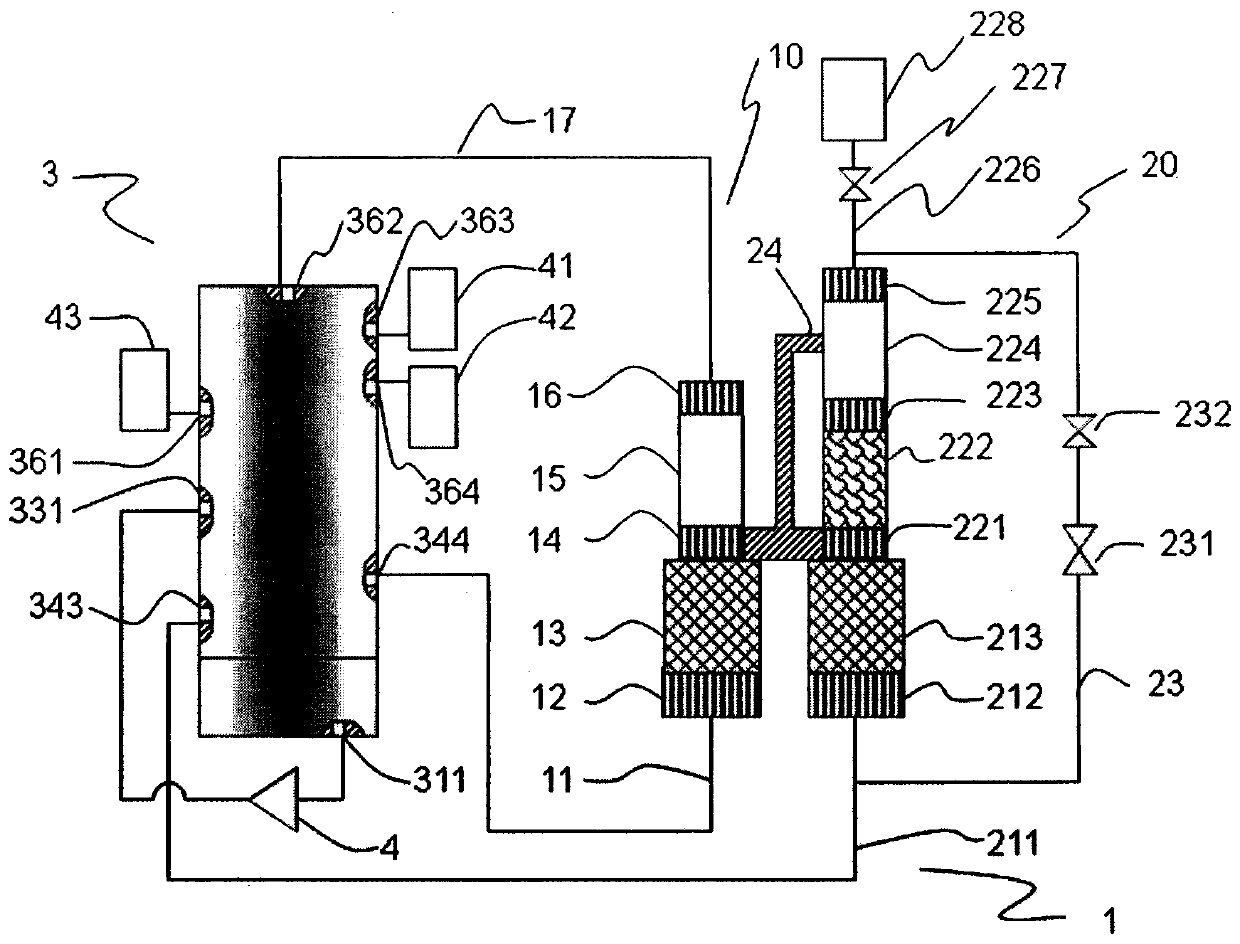

A pulse tube refrigerator

A technology for pulse tube refrigerators and compressors, which is applied in refrigerators, refrigeration and liquefaction, compressors, etc., can solve the problems that cannot be put into large-scale applications, achieve good contact, stable sealing performance, and reduce cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

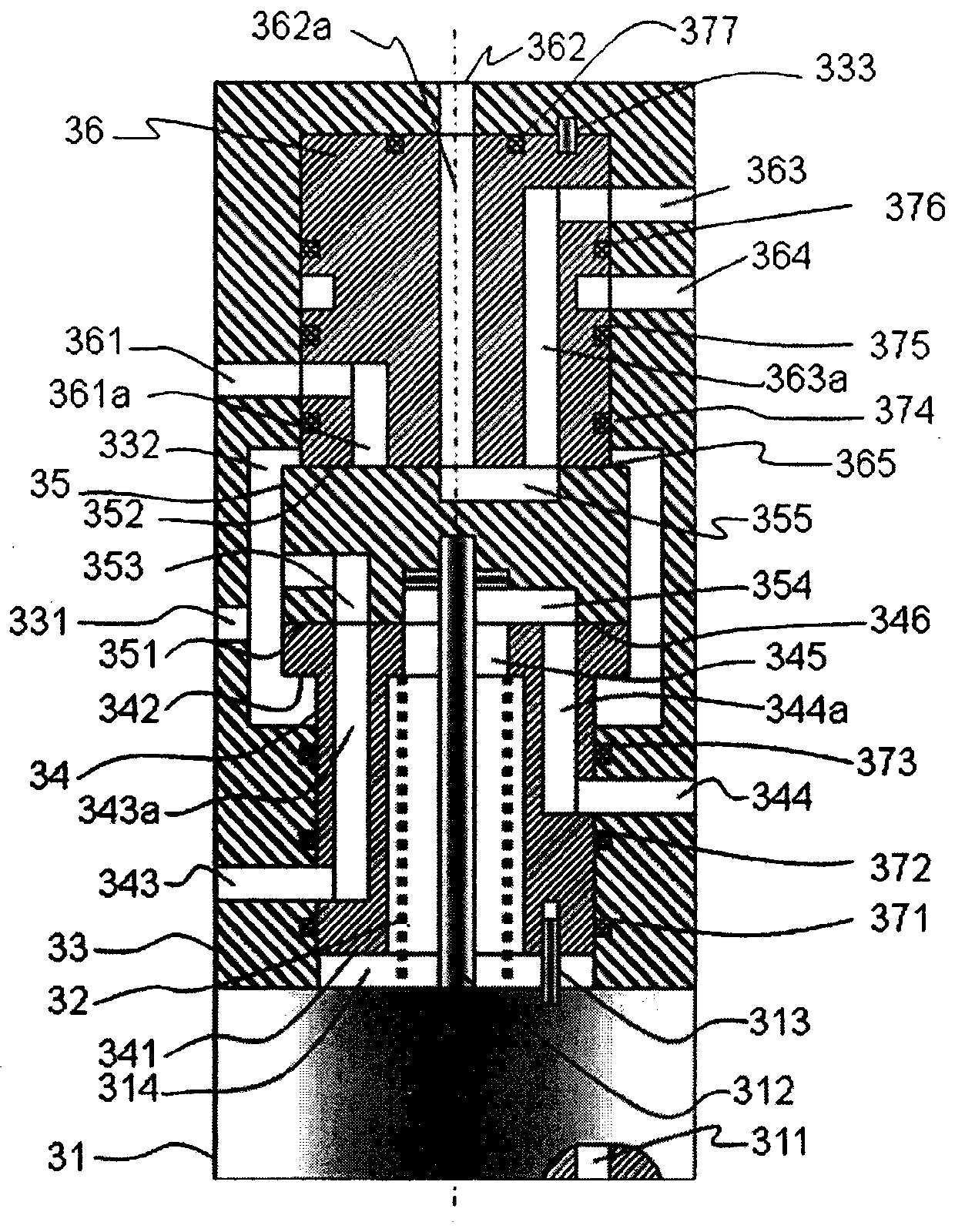

[0033] In Embodiment 2, the first stator 34 and the second stator 36 tightly press the mover 35 together, and the service life is still limited. In order to achieve longer life, the rotor 35 can be supported by bearings, so that it maintains a small gap with the contact surfaces of the first stator 34 and the second stator 36 to obtain a gap seal with a small amount of leakage.

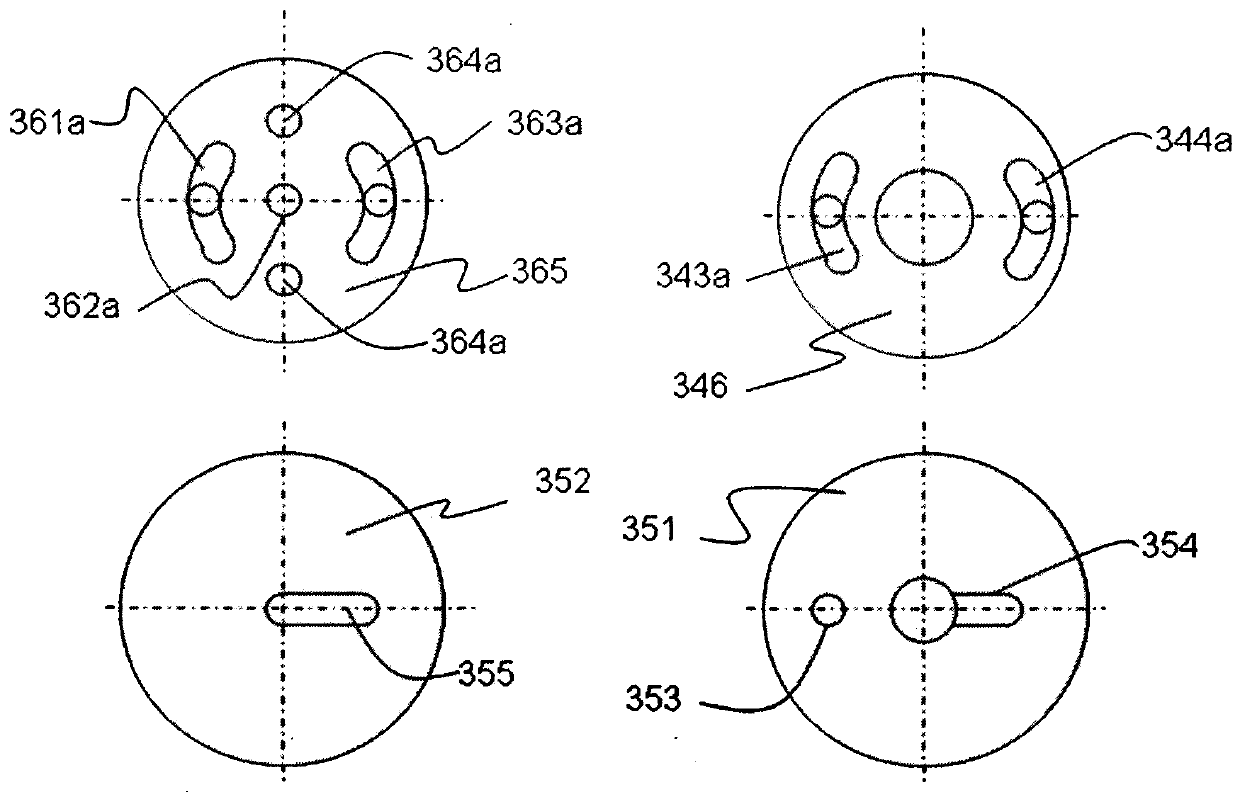

[0034] Figure 4 It is a diagram of the position relationship between the air channels and the grooves on the sealing surface of the rotary valve embodiment 2. In this embodiment, the air channels are symmetrically paired at 180 degrees. In this way, the rotor 35 makes one revolution and the refrigerator works for two weeks. , the advantage of this design is that the surface pressure is balanced, which is conducive to long life. Of course, more air passages and grooves can also be provided, so that the motor rotates once and the refrigerator works for 3 or more cycles.

[0035] Figure 5 Shown is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com