Diesel filter

A diesel filter and filter element technology, which is applied in the direction of machines/engines, engine components, liquid fuel feeders, etc., can solve problems such as obstruction and influence on fuel fluidity, and achieve improved filtration efficiency, good sealing, and elimination of flow The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

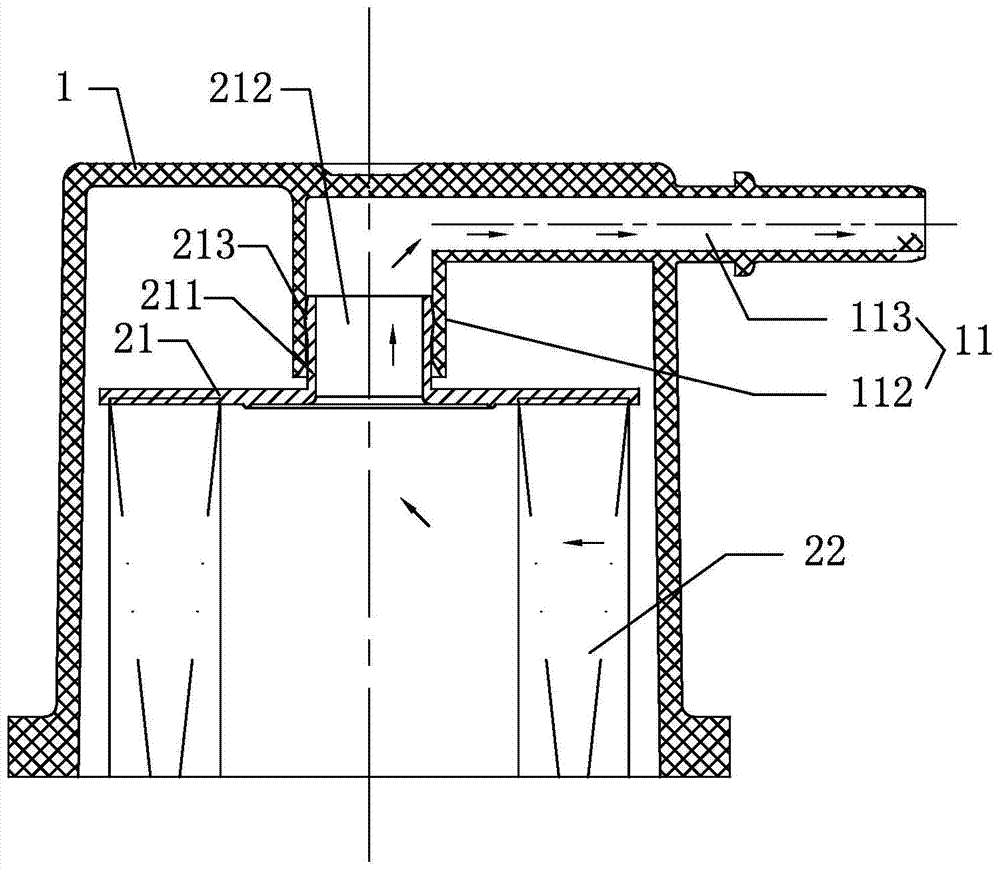

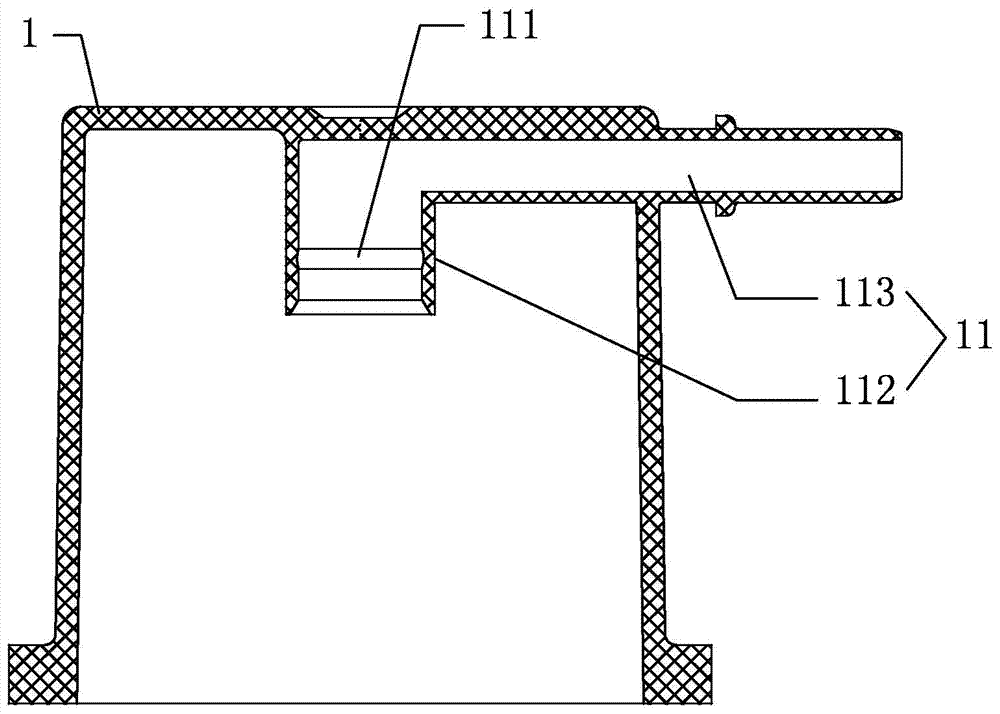

[0022] Such as Figure 5 As shown, the difference from Embodiment 1 is that the inner wall of the oil outlet pipe 11 of the housing is provided with a circle of stepped surface 114, and the boss 211 of the filter element end cover is sleeved in the oil outlet pipe 11 of the housing and then abuts against the stepped surface 114. The diameter of the part of the oil outlet pipe 11 located above the stepped surface 114 is equal to the inner diameter of the through hole 212 . After adopting this structure, since the diameter of the casing oil outlet pipe 11 located above the step surface 114 is equal to the inner diameter of the through hole 212, there is no resistance and no vortex when the fuel flows through the joint of the two, and the flow effect is good , High fuel filtration efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com