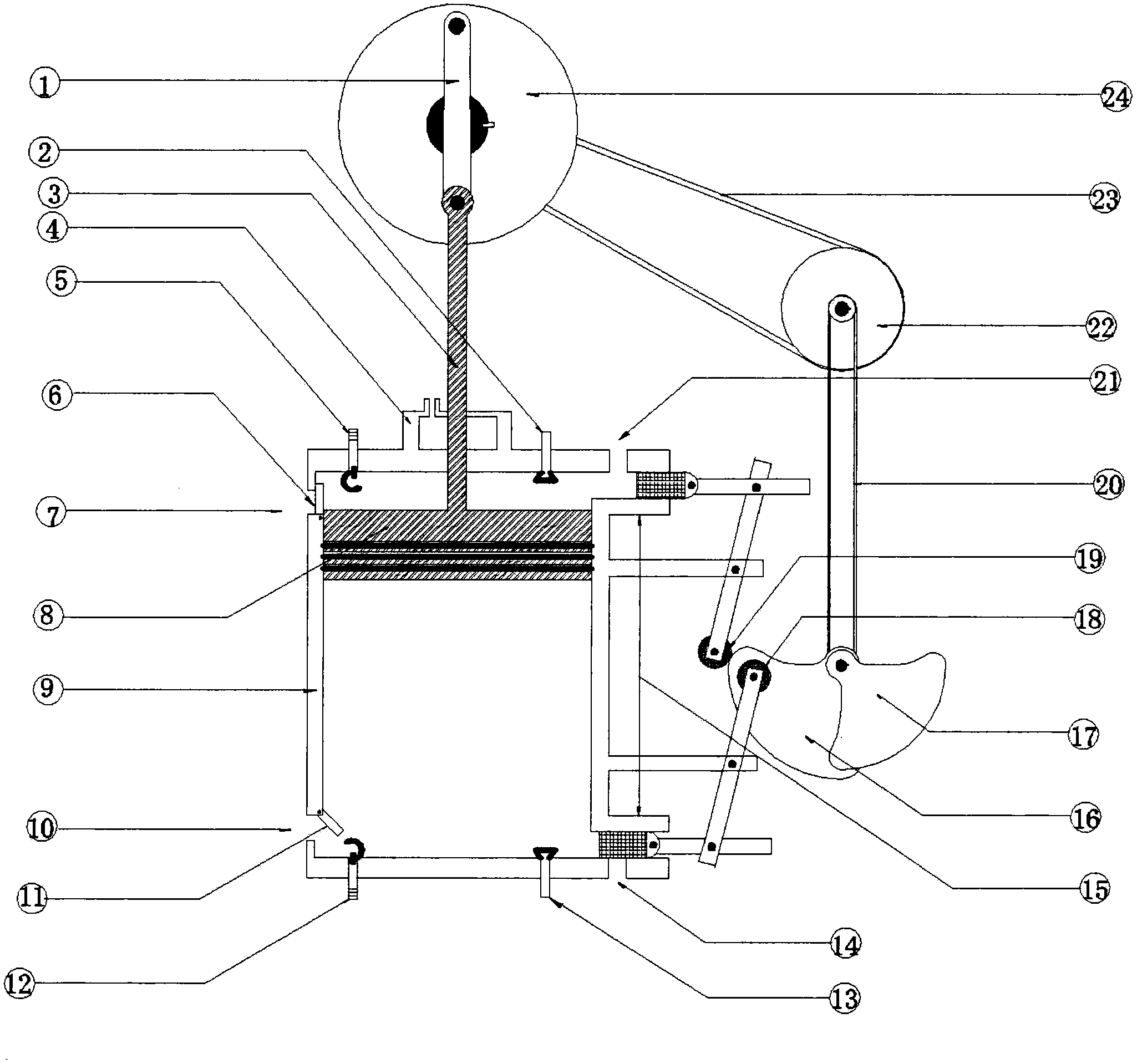

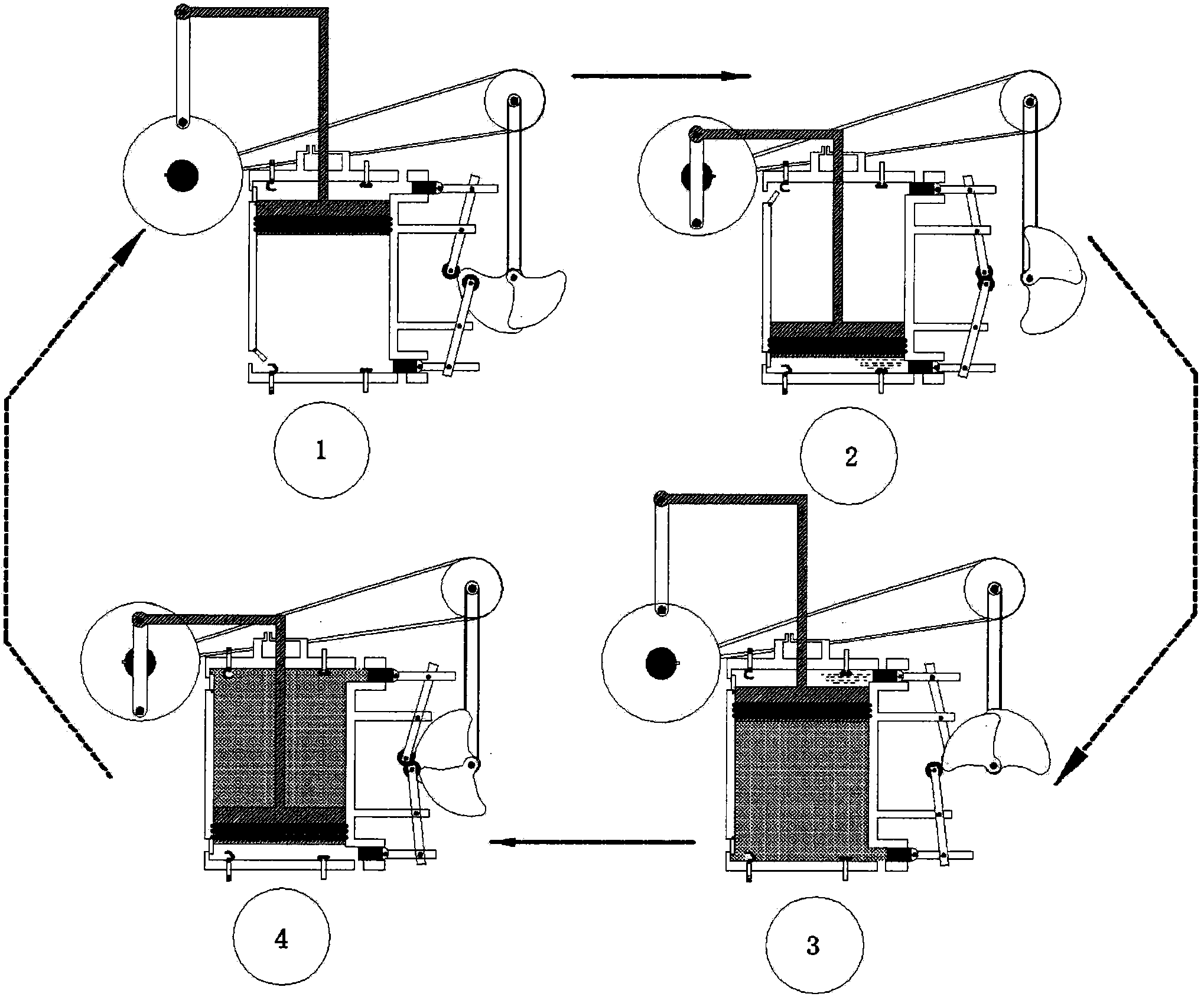

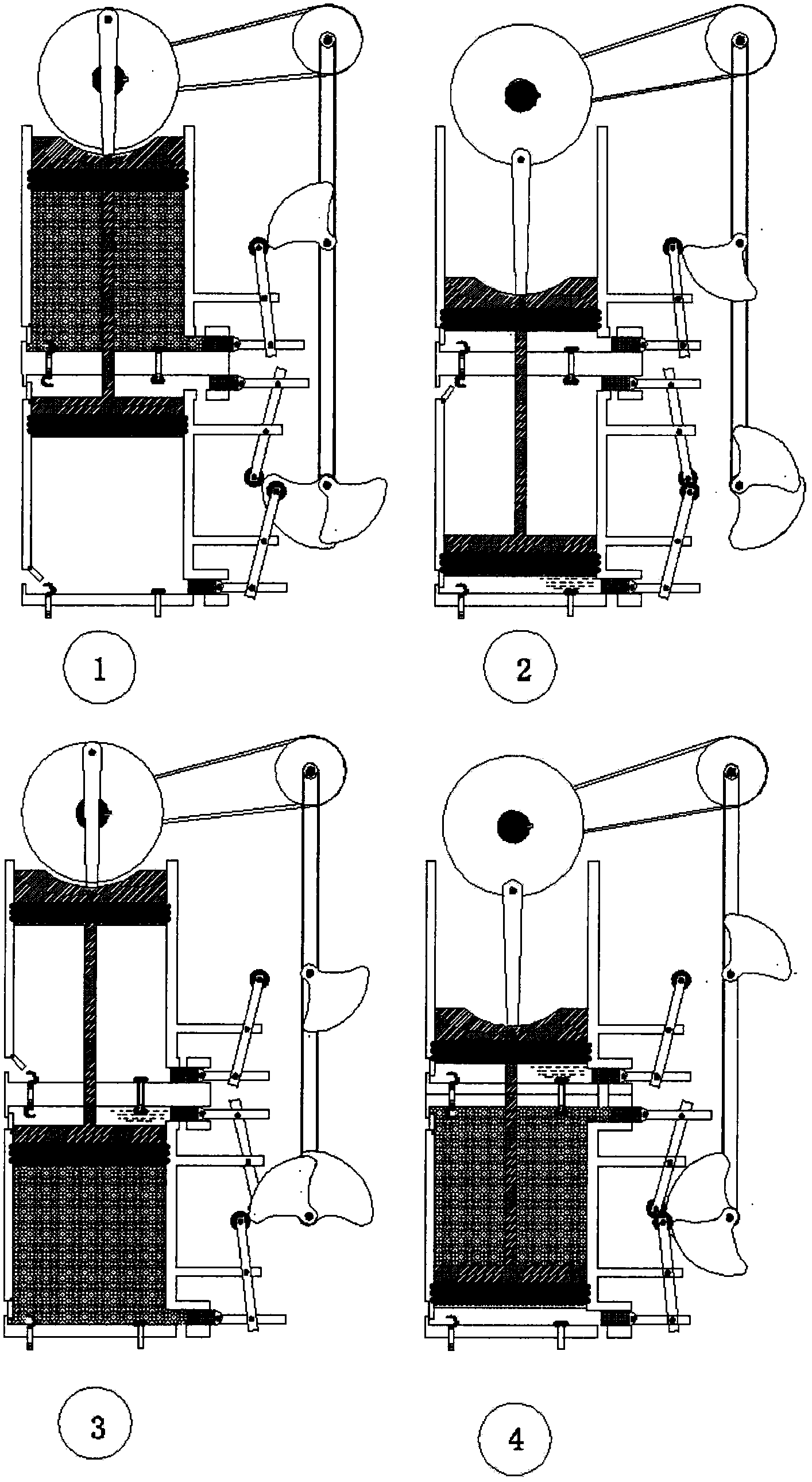

Multi-cycle internal combustion engine

An internal combustion engine and multi-cycle technology, applied to the internal combustion engine cycle principle and the field of high-power internal combustion engines, can solve problems such as technical difficulties, small torque, and difficulty in repairing large-scale markets, and achieve increased power density, reduced volume, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Rely on external force, rotate Flywheel, flywheel drives ⑧ piston and 1 / 2 reduction wheel Sport, 1 / 2 reduction wheel via 90° eccentric wheel The movement controls the state of each intake and exhaust switch, and controls the switch of the igniter and the fuel injection head, so that it can complete several arbitrary groups of four-stroke cycles. After the stable cycle of each four-stroke cycle in the machine, the external force is removed, and the internal combustion engine will work normally. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com