Prefabricated assembly type anti-buckling steel plate shear wall tall building structure system

A steel plate shear wall and prefabricated assembly technology, applied in building components, building structures, buildings, etc., can solve problems such as affecting construction speed and performance, labor-intensive construction workers, and inability to adapt to houses, etc., and achieve convenient construction sites. Simple work and connection structure, realizing the effect of building energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

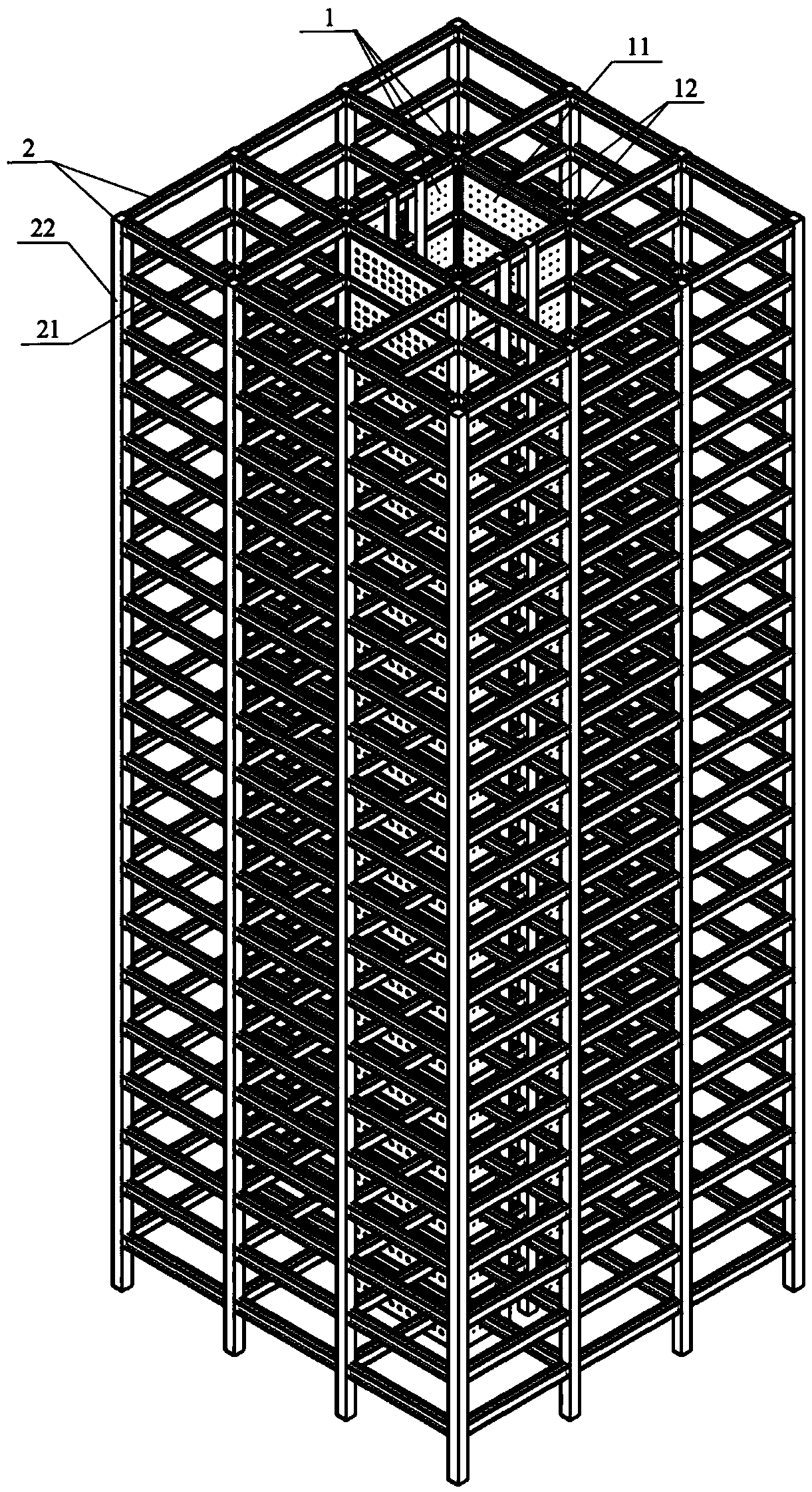

[0029] Such as figure 1 As shown, a prefabricated prefabricated anti-buckling steel plate shear wall high-rise building structure system includes a prefabricated frame beam 21 for a high-rise building structure system, a prefabricated frame column 22 for a high-rise building structure, and edge members 12 and the anti-buckling steel plate wall 11 used for the lateral force energy dissipation of the building structure. The anti-buckling steel plate wall 11 is prefabricated at the production site and assembled at the production site.

[0030] Such as Figure 3-4 As shown, the anti-buckling steel plate wall 11 includes an embedded steel plate 111, an anti-buckling member 112, and a connecting member 113. The anti-buckling member 112 is arranged on both sides of the embedded steel plate 111. It is a concrete plate structure and is used to suppress the embedded steel plate 111. Buckling, the anti-buckling member 112 is connected as a whole by the anti-buckling member 112 penetrating on...

Embodiment 2

[0039] The rest is the same as embodiment 1, the difference is that, as figure 2 As shown, the prefabricated anti-buckling steel plate shear wall 1 and the prefabricated frame beam 21 in the prefabricated frame structure 2 are spliced to each other to form a prefabricated anti-buckling steel plate frame-shear wall high-rise building structure system. It is not only located in the center of the high-rise building structure or the elevator shaft, but can also be located at the edge or any part of the high-rise building structure, as the first seismic line of defense of the structure, yield first, play the role of energy dissipation and shock absorption, and protect the safety of the main structure .

[0040] The embedded steel plate 111 is a flat steel plate without grooves, which can be directly used as a yield steel plate to increase the lateral rigidity of the building structure.

[0041] Such as Image 6 As shown, in order to make the connecting member 113 have better mechanic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com