Flame retardant impregnation device for foamed plastic board

A technology of foam plastic board and dipping device, which is applied in the direction of coating, etc., can solve the problems of low strength, poor fireproof effect, impregnation of dipping device, etc., and achieve the effect of small equipment volume, energy consumption and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below through specific examples.

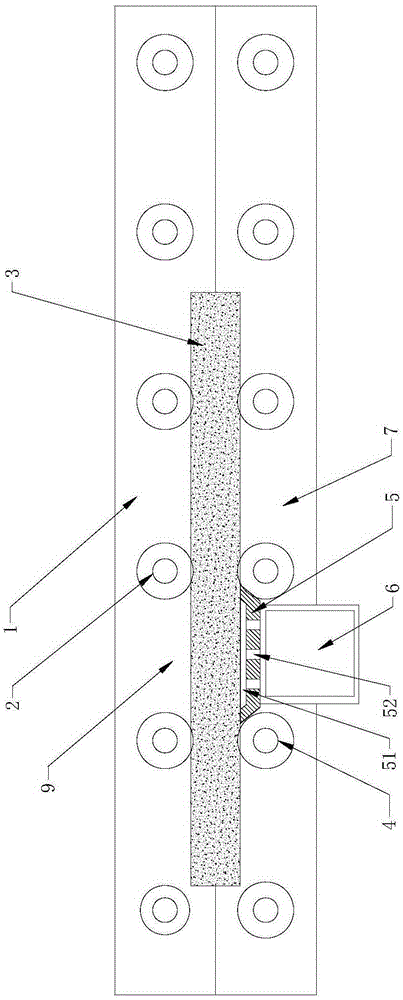

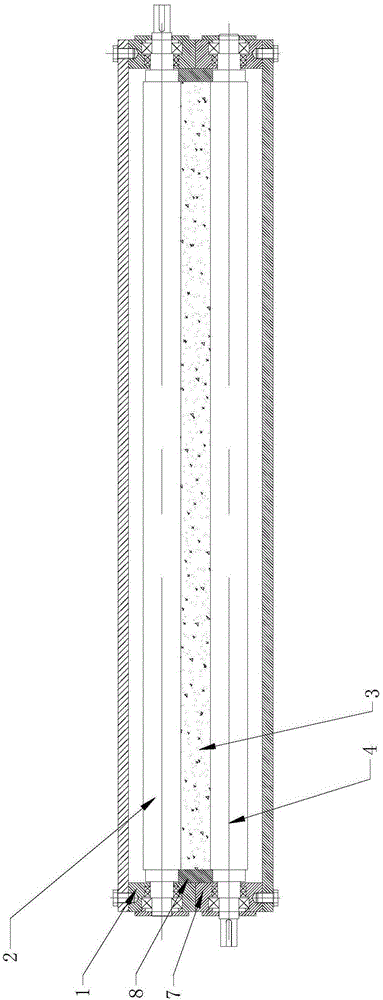

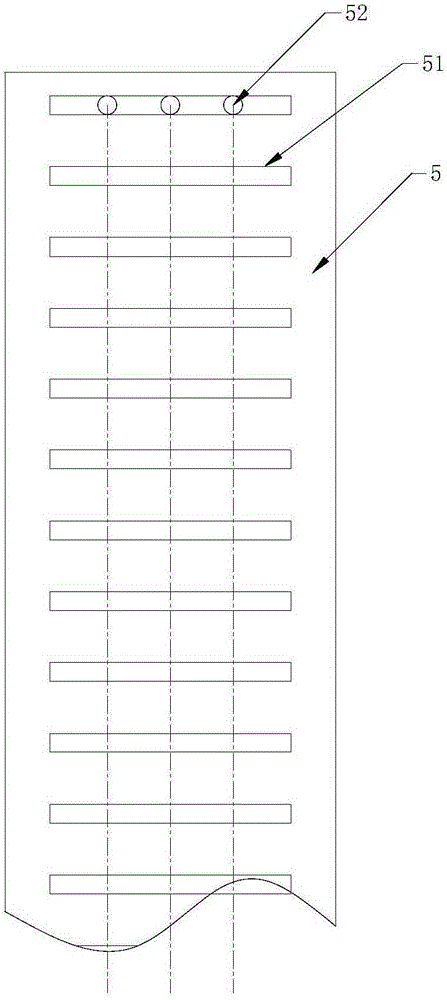

[0022] Such as figure 1 , 2 , As shown in 3, a flame retardant impregnation device for foamed plastic boards, including a frame, an upper conveying roller set, a lower conveying roller set, and a vacuum impregnation mechanism. Of course, the number of the vacuum impregnation mechanism can also be multiple, and it is arranged on the frame along the conveying direction of the conveying roller group, then the foamed plastic board will pass through each vacuum impregnation mechanism in turn during operation, so that the customer can choose how many to use. A vacuum impregnation mechanism achieves the best penetration effect.

[0023] Two parallel side roller frames are installed on the frame, and the side roller frames are used as fixed supports for the upper and lower conveyor roller groups, and the side roller frames include an upper roller frame 1 and a lower roller frame 7, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com