Automatic hub casting device and method

A wheel hub and traveling wheel technology, applied in casting equipment, manufacturing tools, equipment for feeding molten metal into casting molds, etc., can solve the problems of complex equipment structure, high equipment cost and difficult operation, and achieve simple and convenient operation, Low cost and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

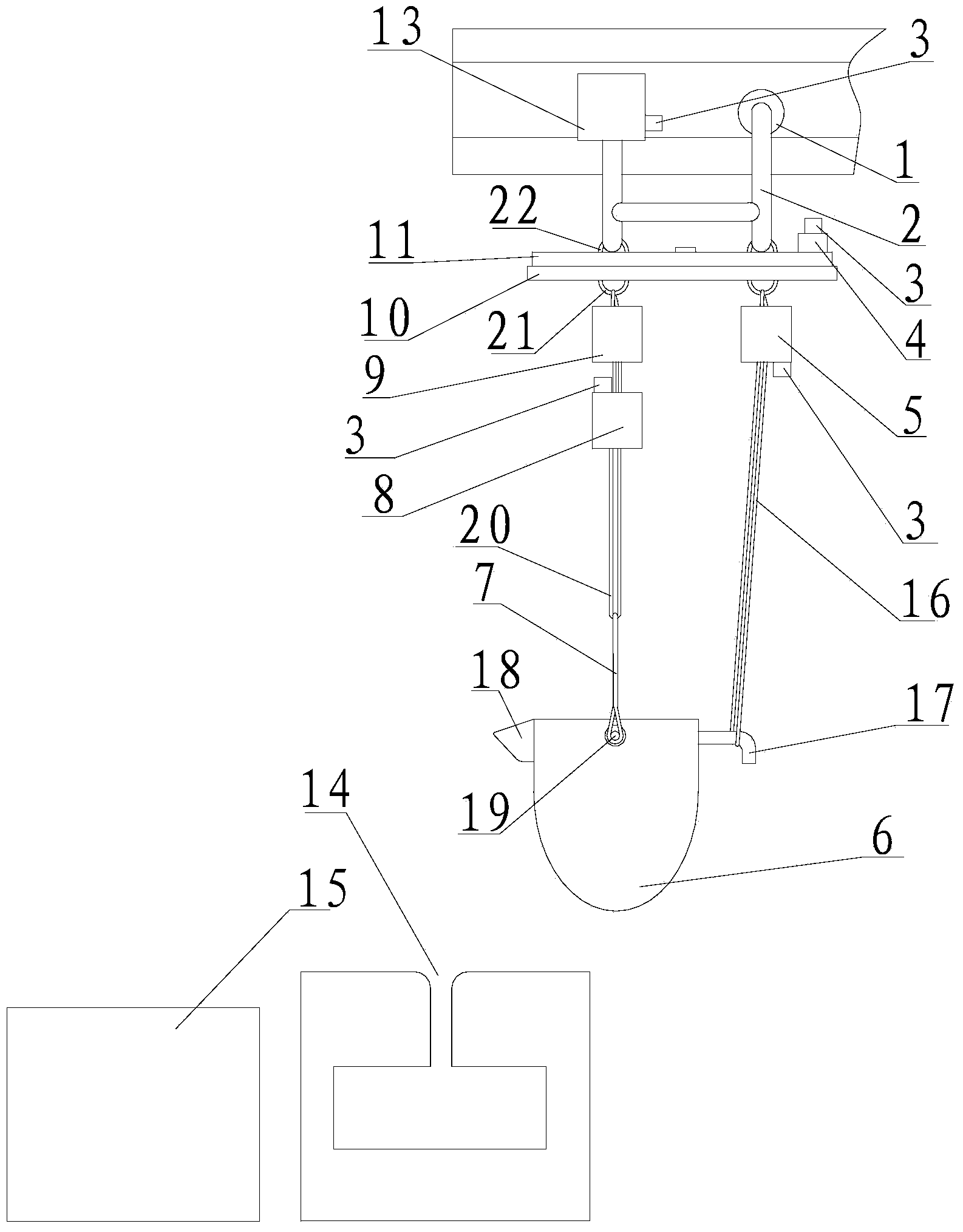

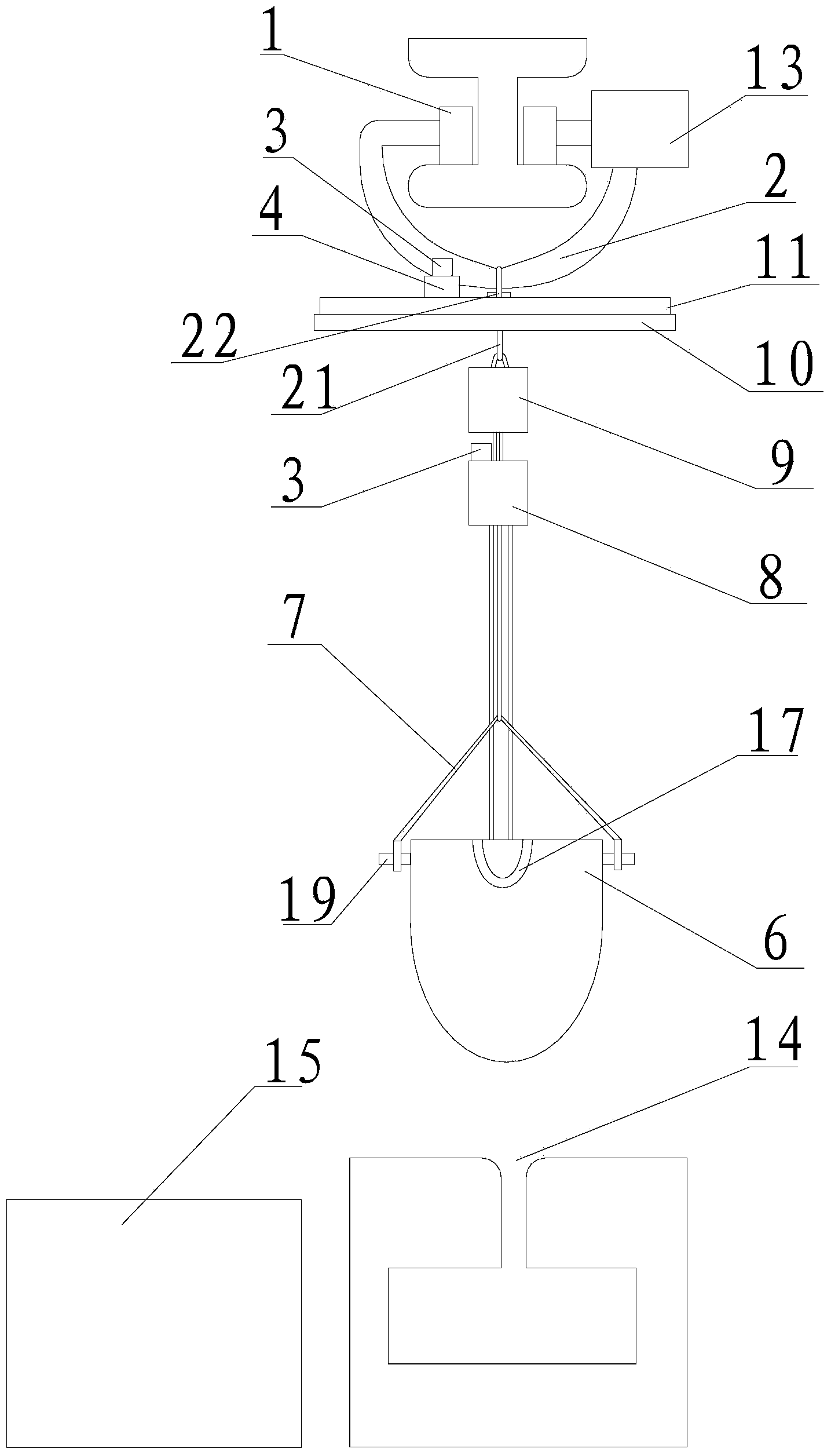

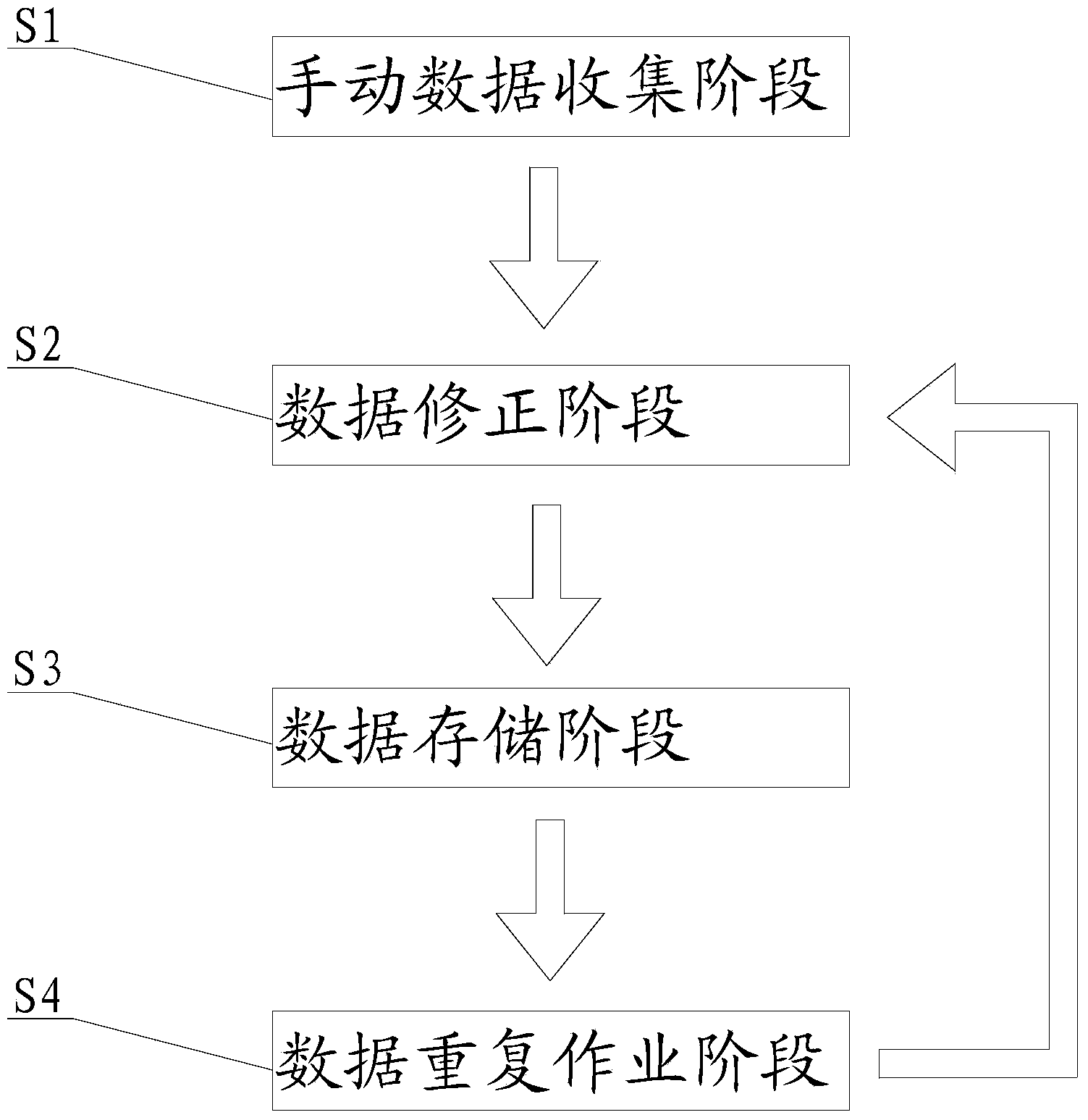

[0020] refer to figure 1 , figure 2 , an automatic casting device for hubs according to the present invention, comprising a traveling wheel 1, a lifting motor 8, a traveling motor 13, a frame 2, an upper turntable 11, a lower turntable 10, a steering motor 4, a pouring ladle 6, a pouring motor 5, lifting lugs 19, Lifting wire rope 20, lower hanging ring 21, speed measuring sensor 3 and electronic scale 9, described traveling wheel 1 is installed on the frame 2, and described traveling motor 13 is installed with frame 2, and described steering motor 4 is installed on the upper turntable 11 The upper part, the electronic scale 9 and the pouring motor 5 are fixedly installed with the lower hanging ring 21 and the lower loading plate, the lifting motor 8 is installed at the bottom of the electronic scale 9, the lifting lug 19 is located on the ladle 6, the lifting lug 19 Hingedly installed on the hanger 7, the hanger 7 is connected with the lifting motor 8 by a lifting wire rope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com