Hand riveter

A technology of rivets and rivet heads, applied in the field of manual rivets, to achieve the effect of increasing mechanical advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

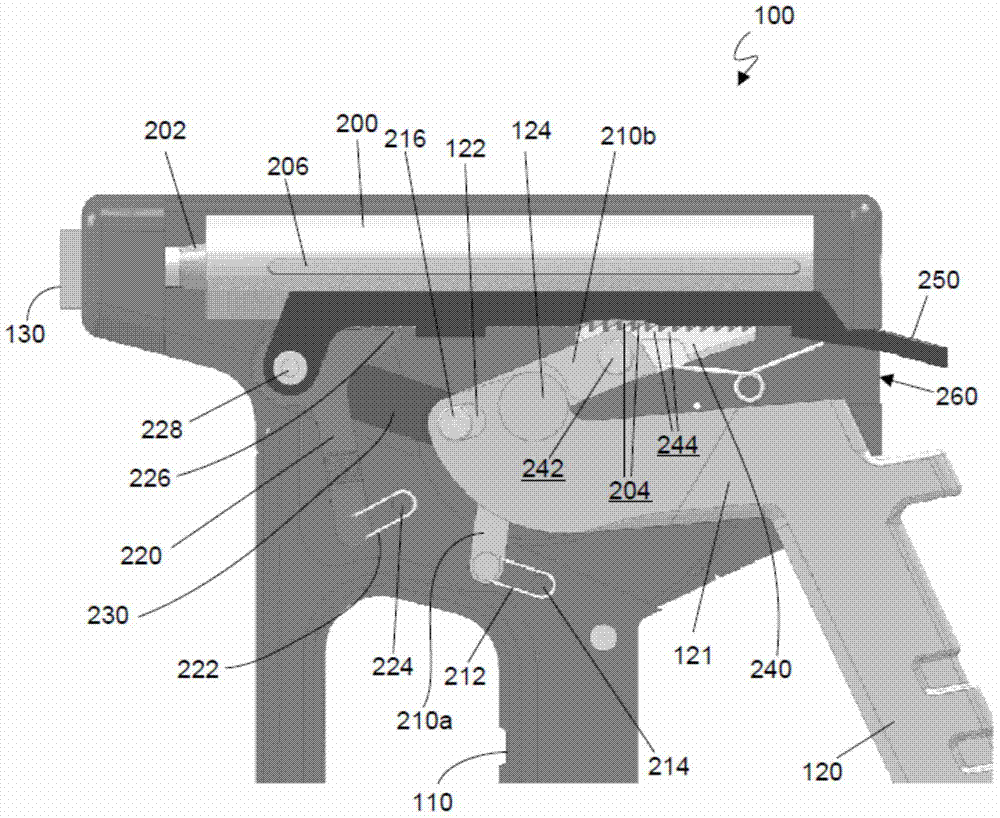

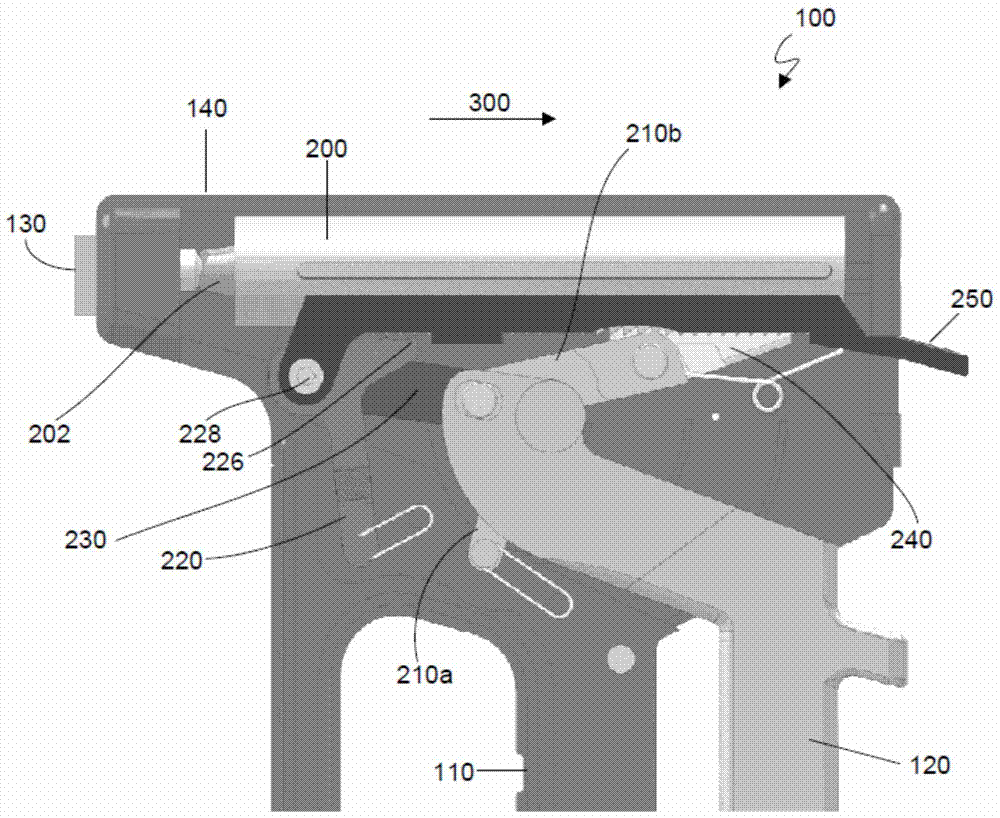

[0023] Referring to the drawings, hand riveter 100 includes a housing 140 having a mouth piece 130 for receiving a mandrel of a blind rivet. For simplicity, rivets are omitted from the drawings. The hand riveter 100 has a handle 110 and a handle 120 that can be squeezed to apply force to the mandrel. The handle 120 is mounted within the housing 140 and is capable of pivotal movement around a pivot point 124 ( figure 2 ).

[0024] The mandrel tensioning device mounted within the housing 140 includes a barrel 200 that houses a pair of jaws 202 that grip the mandrel. The jaws 202 are supported by compression springs within the barrel 200 . An inner cone located at the barrel opening allows the jaws to close the mandrel. Bucket 200 has elongated slots 206 that slide over tracks or other protrusions on the inner surface of housing 140 .

[0025] Helical teeth 204 located on the lower surface of bucket 200 and extending the main portion of its length are sized and shaped to ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com