Flanging and patting device for metal thin-walled cylindrical vessels

A thin metal and cylindrical technology, applied in the field of flanging and flattening devices for metal thin-walled cylindrical vessels, can solve the problems of expensive mold material processing costs, occupation of production time and labor, and long manufacturing cycle, so as to achieve convenient and rapid production and save Improvement in installation and commissioning time and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

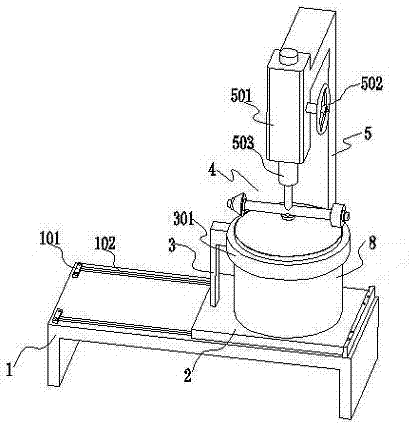

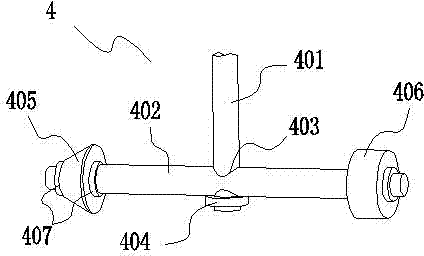

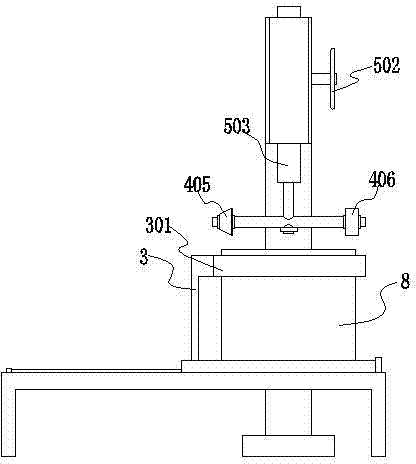

[0030] Such as Figure 1-4 As shown, the connection relationship of the present invention is: it includes a base 1, a base plate 2 is provided on the base 1, a support 3 is provided on the base plate 2, and a support ring 301 is provided on the support 3; A molded body 4 is arranged above the bracket ring 301, and the molded body 4 is arranged on the rotating device 5; the molded body 1 includes a rotating shaft 401 connected to the rotating device 5, and a cross bar 402 connected below the rotating shaft 401, the A forming head 405 and a flattening head 406 are respectively provided at both ends of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com