Photoelectric catalytic unit and photoelectric catalytic method

A technology of photoelectric catalysis and photocatalytic thin film, which is applied in the chemical/physical/physical chemical process of applying energy, etc., to achieve the effects of strong controllability, improved utilization of light energy, and improved photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Coat 1mL of 0.5g / L graphene oxide dispersed in water on the surface of the thermoelectric device and dry it in a constant temperature drying oven at 60°C; refer to the literature (J.Phys.Chem.C2012,116,19413–19418.) to prepare FTO / Bi 2 WO 6 nano film;

[0052] Connect one end of the thermoelectric device to the FTO / Bi through conductive glue 2 WO 6 Fabrication of photocatalytic devices on nanofilms.

[0053] figure 1 It is a schematic diagram of a photoelectric catalysis device using thermoelectric devices and photocatalytic materials in this embodiment.

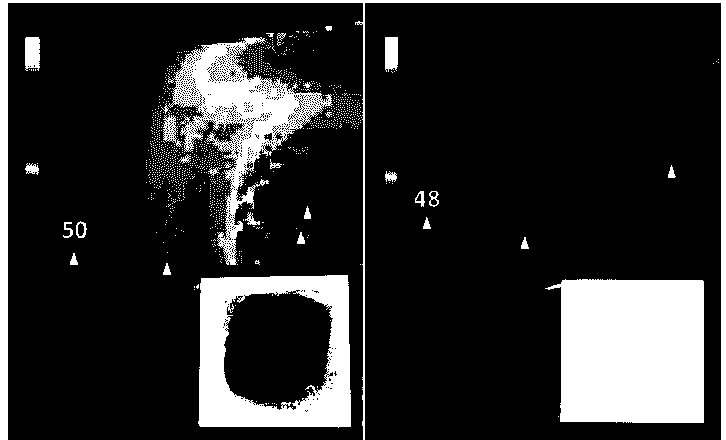

[0054] figure 2 It is the thermal imaging picture of the thermoelectric device in the present embodiment under the irradiation of infrared light, figure 2 In a is a thermoelectric device coated with a layer of graphene oxide, figure 2 where b represents an uncoated thermoelectric device. Depend on figure 2 It can be seen that after coating a layer of graphene oxide, the temperature difference between th...

Embodiment 2

[0059] The only difference between this embodiment and embodiment 1 is that the photocatalytic film adopted is commercialized TiO 2 (P25) deposited on the FTO film;

[0060] The rest of the content is exactly the same as described in Example 1.

[0061] After detection and analysis, it is known that: in this embodiment, the thermoelectric device and TiO 2 The photocatalytic degradation efficiency of phenol in water after photocatalytic film combined is higher than that of pure TiO 2 The photocatalytic degradation efficiency has been significantly improved.

Embodiment 3

[0063] The only difference between this embodiment and Embodiment 1 is that the surface coating of the thermoelectric device adopts CuS instead of graphene oxide;

[0064] The rest of the content is exactly the same as described in Example 1.

[0065] After detection and analysis, it is known that the temperature difference between the two ends of the thermoelectric device coated with CuS in this embodiment is significantly higher than that of the same condition without coating, and the temperature difference between the thermoelectric device and Bi 2 WO 6 The photocatalytic degradation efficiency of phenol in water after the combination of photocatalytic film is higher than that of pure Bi 2 WO 6 The photocatalytic degradation efficiency is also significantly improved.

[0066] The implementation of the invention does not require special equipment and harsh conditions, the process is simple, the controllability is strong, it is easy to realize large-scale production, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com