Hot air drying technology and device for Chinese wolfberries

A technology of hot air drying and wolfberry, which is applied in the direction of drying gas arrangement, drying, drying machine, etc., can solve the problems of large difference in water change, too fast evaporation of fruit surface, cracking of fruit surface, etc., and achieve humidity balance and drying Good consistency and low mildew rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

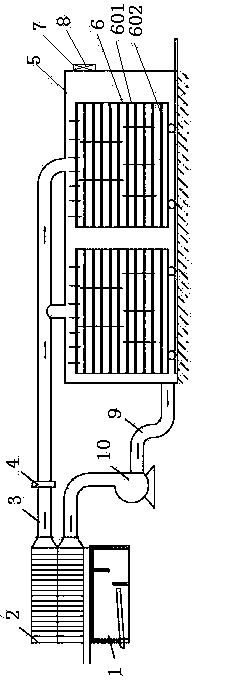

Image

Examples

Embodiment Construction

[0023] A hot-air drying process for wolfberry, comprising the following process steps:

[0024] 1) Selection of raw materials: After manual identification and screening, unfulfilled granules, impurities and mildewed goji berries are manually and screened to keep fresh goji berries with uniform particle size, no impurities and mildew;

[0025] 2) Cleaning: Wash with clean water to remove dust and other attached particles on the surface of wolfberry;

[0026] 3) Soaking in the dewaxing desiccation accelerator: Soak the cleaned wolfberries in the dewaxing desiccation accelerator for 10-20 seconds and then remove; the ratio of the dewaxing desiccation accelerator by weight is:

[0027] Vegetable oil: Ethanol: NaOH: Na 2 CO 3 : Na 2 S 2 o 5 =10:4:3:65:8;

[0028] 4) Drain: Put the taken out goji berries on the drying sieve to drain; spread the drained goji berries evenly and put them into the drying bed together with the drying sieve. The thickness of the fresh fruit is cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com