Seed-dressing agent as well as preparation method and application thereof

A technology for seed dressing and raw materials, which is applied to the field of seed dressing with plant raw materials, can solve the problems of reducing drug efficacy and cannot be applied in large quantities, and achieves the effects of low cost, good extraction rate, and good disinfection and sterilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

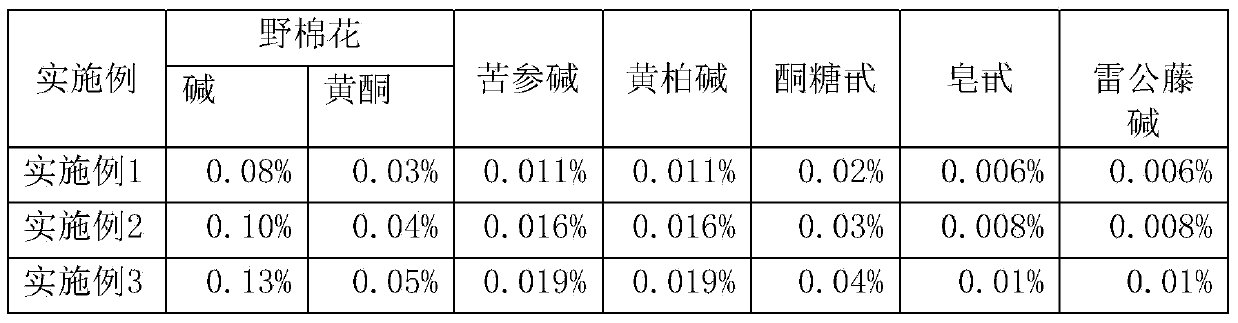

Embodiment 1-3

[0024] Prepare the seed dressing:

[0025] a, get the raw material according to the ratio listed in Table 1, crush through a 35 mesh sieve and cut into 2 cm long sections for subsequent use.

[0026] b. Take 1 part of the raw material prepared in the step a by weight and mix it with 20 parts of water, put it into a cooking tank and heat it under reduced pressure until the liquid boils, and then heat-preserve and extract for one hour, filter, discard the residue, and take the extract for subsequent use;

[0027] c. Pack the extract into a concentration tank and concentrate to saturation to obtain a concentrate;

[0028] D, in the concentrated solution that step c obtains, slowly add the 1% mass percent concentration of concentrated solution weight ratio and be 37% hydrochloric acid, the molybdic acid of 0.1% and the mass percent concentration of 0.2% are phosphoric acid, stir, then be warming up to liquid boiling , keep warm for 40 minutes, stir once every 20 minutes, stop th...

Embodiment 4-6

[0037] Prepare the seed dressing:

[0038] a, get the raw material according to the ratio listed in Table 1 and crush through a 50 mesh sieve and cut into 3 cm long sections for subsequent use.

[0039] b. Take 1 part of the raw material prepared in step a by weight and mix it with 30 parts of water, put it into a cooking tank and heat it at normal pressure until the liquid boils, then heat-preserve and extract for one hour, filter, discard the residue, and take the extract for subsequent use;

[0040] c. Pack the extract into a concentration tank and concentrate to saturation to obtain a concentrate;

[0041] d, in the concentrated solution that step c obtains, slowly add 2% mass percent concentration of concentrated solution weight ratio to be hydrochloric acid, 0.2% molybdic acid and 0.5% mass percent concentration to be 85% phosphoric acid, stir evenly, then be heated to liquid boiling , keep warm for 1 hour, stir once every 20 minutes, stop the extraction when crystals ...

Embodiment 7-9

[0052] Prepare the seed dressing:

[0053] a, get the raw material according to the ratio listed in Table 1 and crush through a 42 mesh sieve and cut into 3 cm long sections for subsequent use.

[0054] b. Take 1 part by weight of the raw material prepared in step a and mix it with 25 parts of water, put it into a cooking tank and heat it to a liquid boil under 0.15mpa, then keep it warm for leaching for one hour, filter, discard the residue, and take the leaching solution spare;

[0055] c. Pack the extract into a concentration tank and concentrate to saturation to obtain a concentrate;

[0056] D, in the concentrated solution that step c obtains, slowly add the 1.5% mass percent concentration of concentrated solution weight ratio and be 37% hydrochloric acid, the molybdic acid of 0.15% and the mass percent concentration of 0.35% be 85% phosphoric acid, stir evenly, then be heated up to Boil the liquid, keep it warm for 1 hour, stir once every 20 minutes, stop the extractio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com