Method for etching material longitudinally spaced from etch mask

一种蚀刻掩模、掩模的技术,应用在MEMS装置领域,能够解决表面微加工过程复杂性增加等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

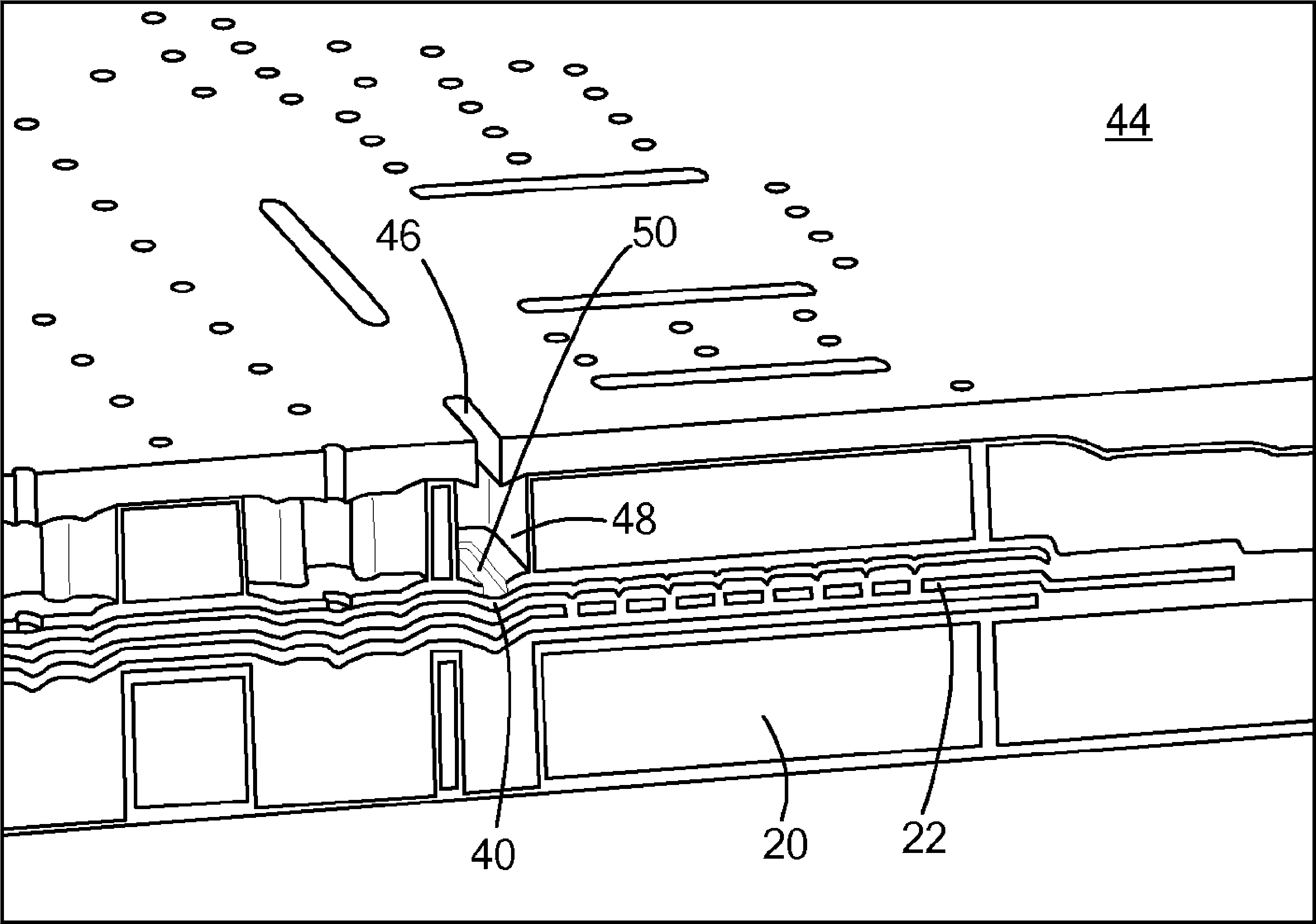

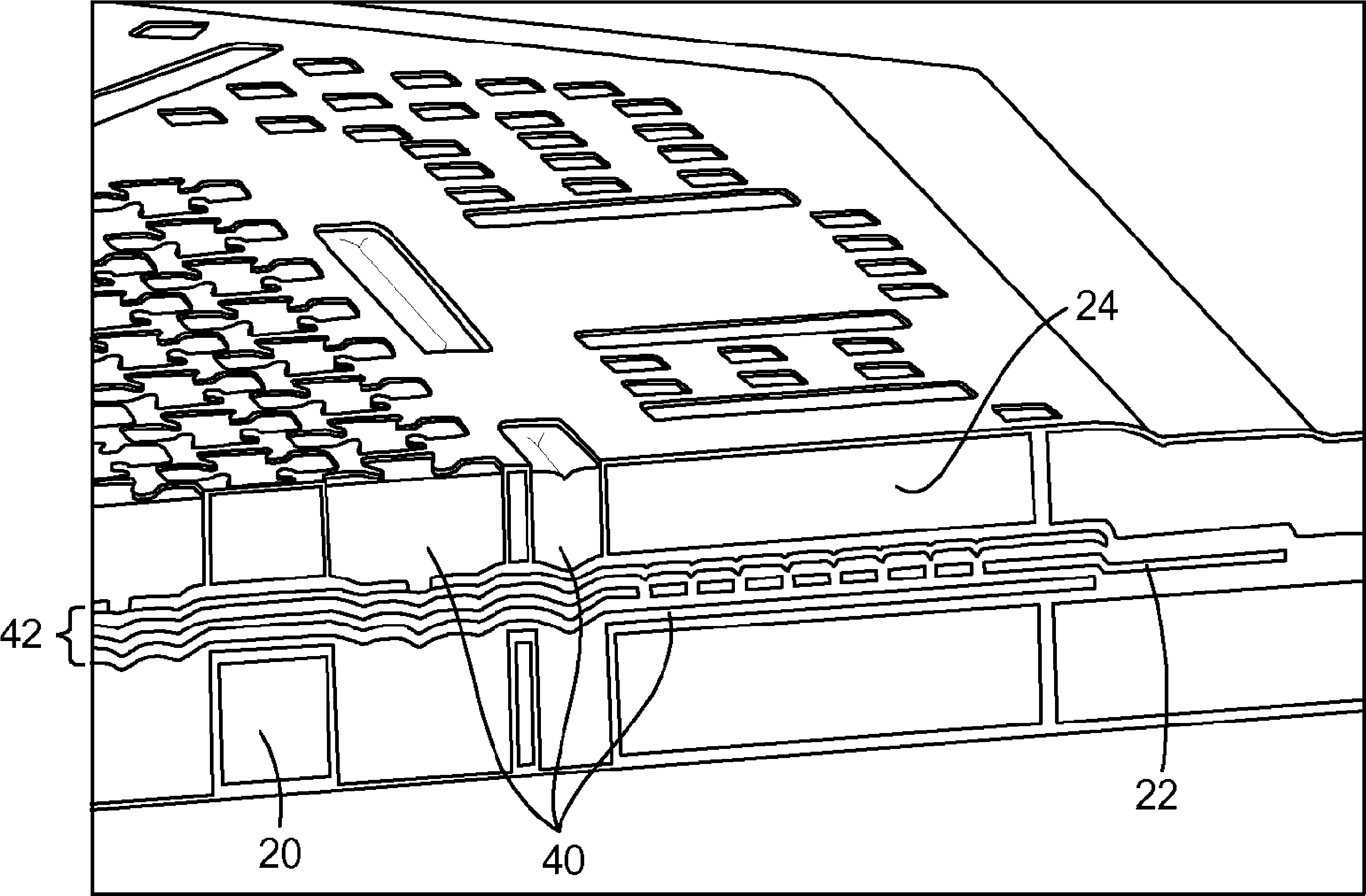

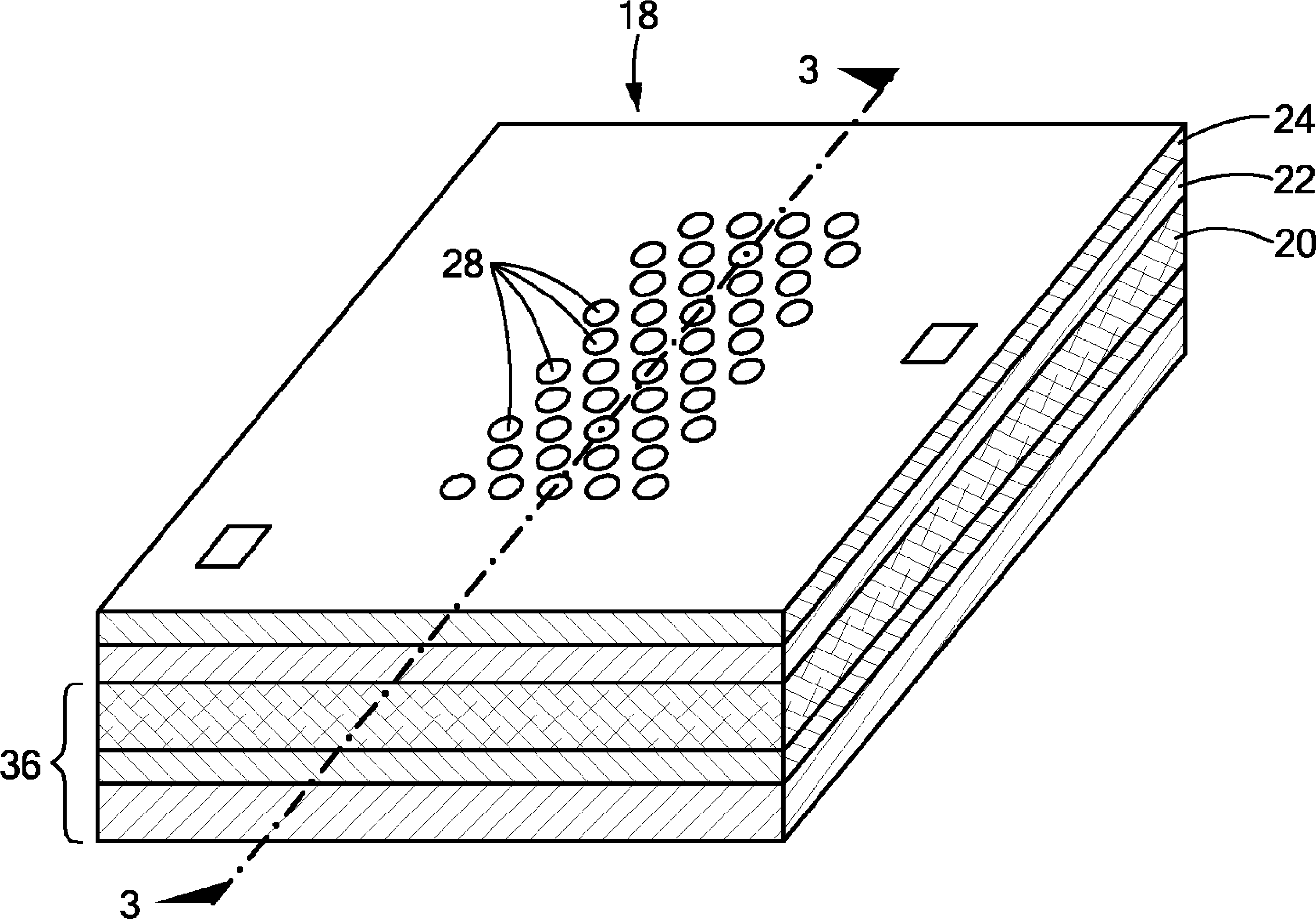

[0029] The illustrative embodiments enable micromachining processes to perform long-reach etching—that is, they mask openings spaced from the surface it etches. As a result, microfabrication processes can now fabricate improved and more robust MEMS devices. For example, the process improves state-of-the-art manufacturing processes to produce more robust dual-backplate MEMS microphones. Details of illustrative embodiments are discussed below.

[0030] figure 1 A mobile telephone 10 that may use a microphone configured and manufactured in accordance with an illustrative embodiment is schematically shown. It should be noted, however, that the discussion of the mobile phone 10 and the specific MEMS device (ie, microphone) is for illustration purposes only and thus is not intended to limit all embodiments of the invention. Accordingly, various embodiments are applicable to other microfabricated devices such as inertial sensors, gas detectors, network switches, etc...

[0031] B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com