MEMS switch contact system

A switch and contact technology, applied in the field of MEMS switches, can solve the problems of reducing switch life, reducing conductivity, reducing effectiveness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

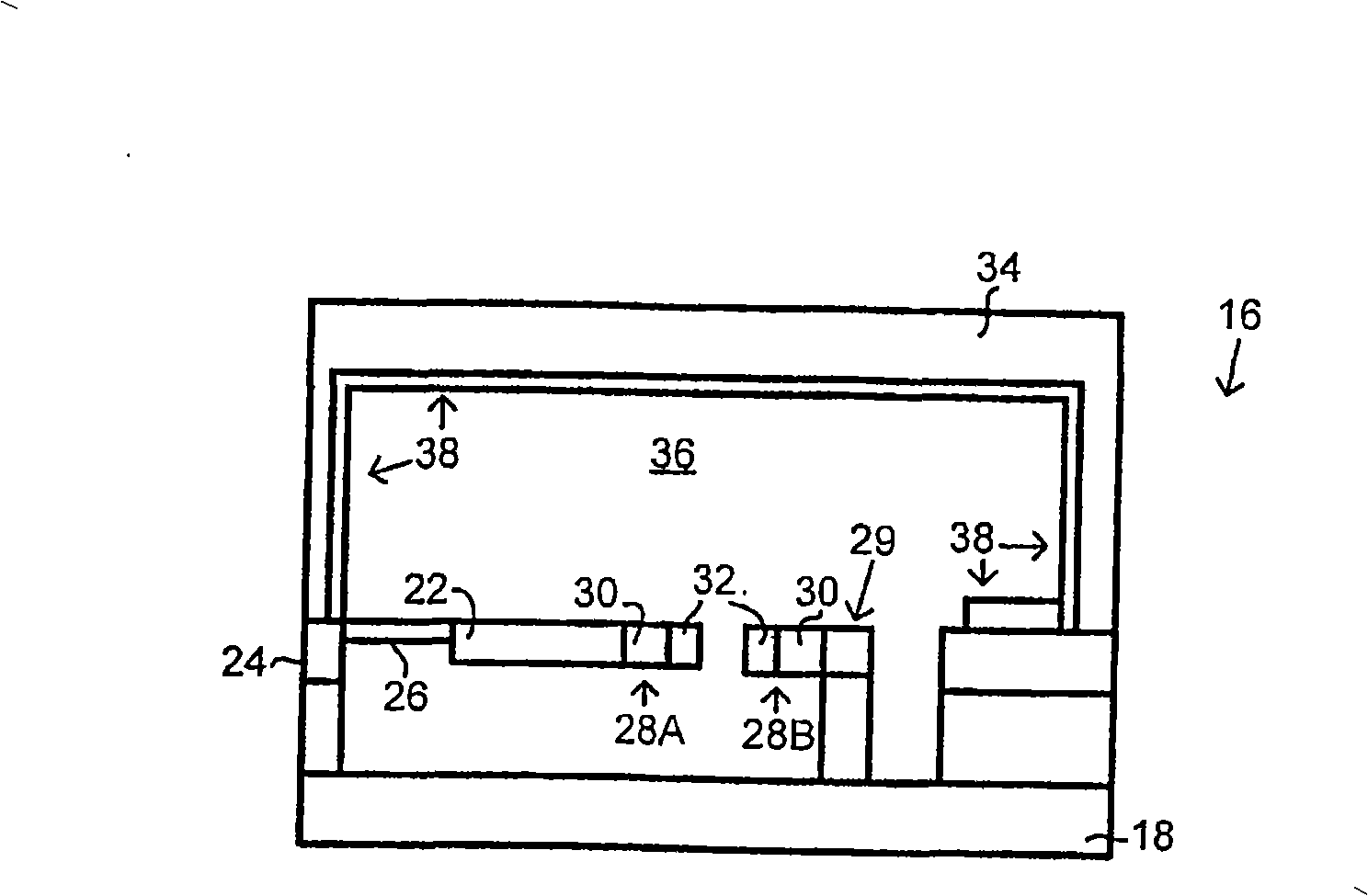

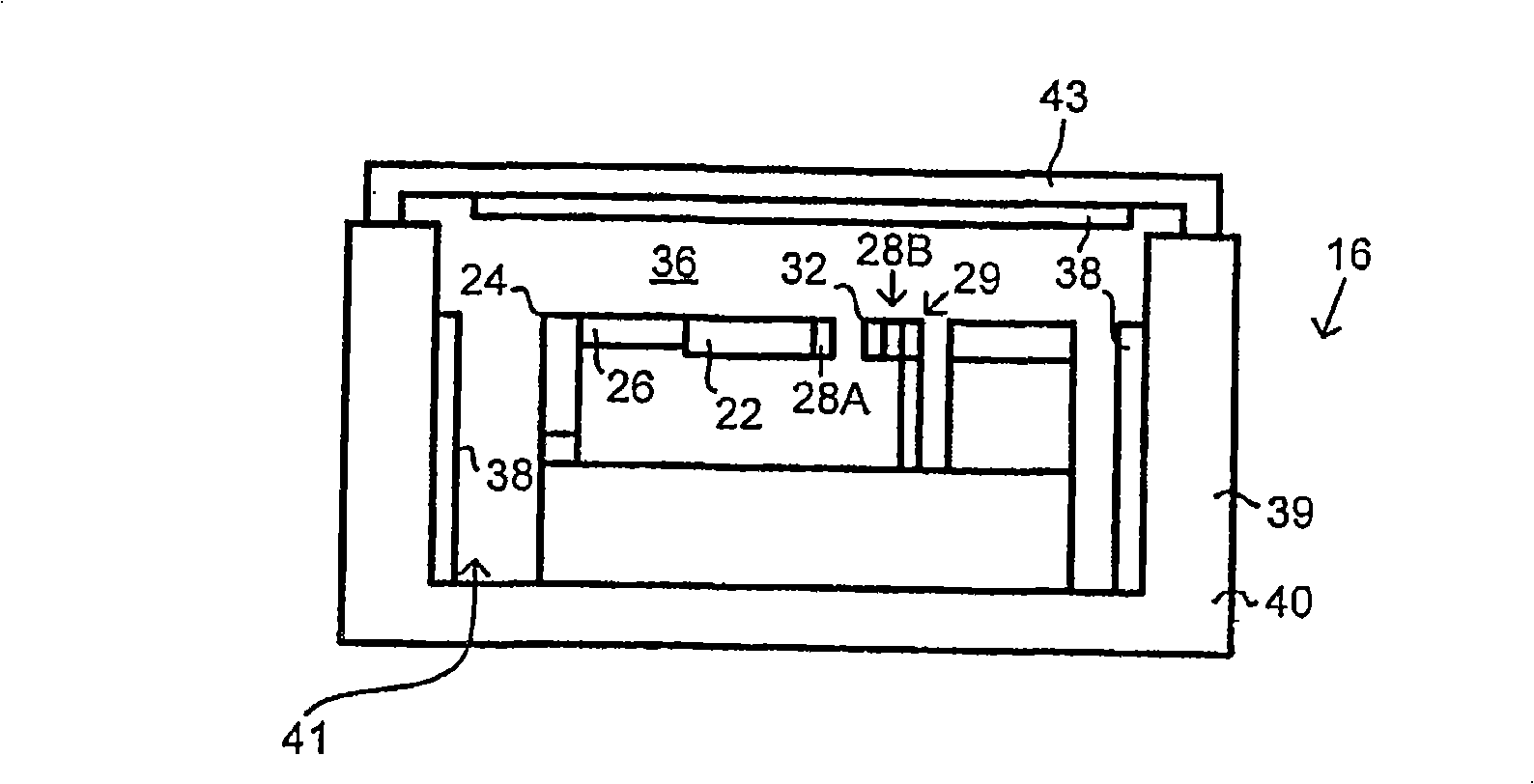

[0016] In an exemplary embodiment, a MEMS switch has contacts formed from a platinum-series-based material. For example, the contact may be formed of ruthenium metal (hereinafter simply referred to as "ruthenium"), ruthenium dioxide, or both. Contacts of this type should have material properties that provide the desired electrical resistance and durability while minimizing undesirable surface contamination layers of the insulation that could degrade switching performance. Details of exemplary embodiments are discussed below.

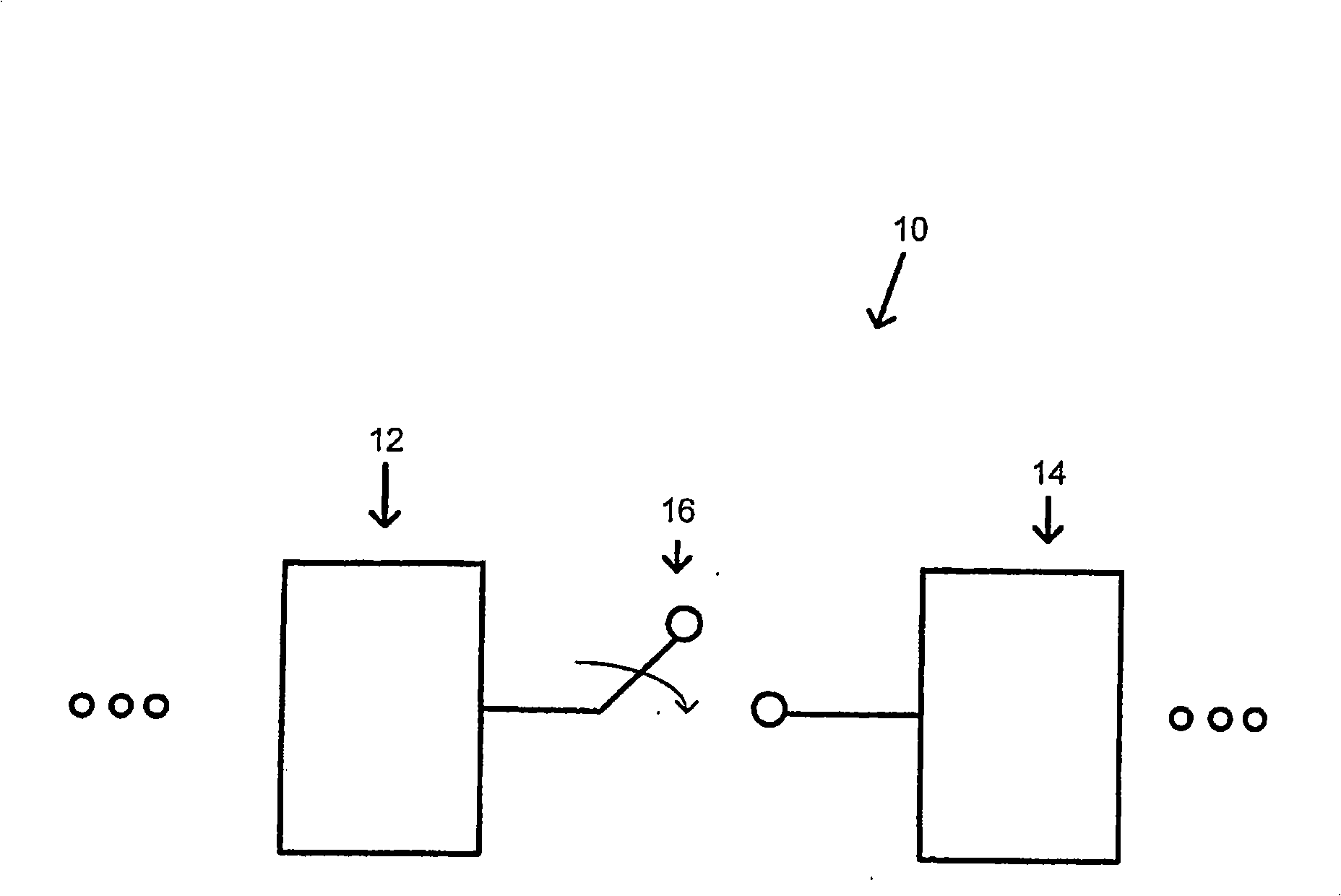

[0017] figure 1 An electronic system 10 is schematically shown utilizing a switch that may be implemented in accordance with an exemplary embodiment of the present invention. Briefly, the electronic system 10 has a first set of components 12 represented by blocks on the left side of the figure, a second set of components 14 represented by blocks on the right side of the figure, and alternately connecting the first and second Switch 16 for group assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com