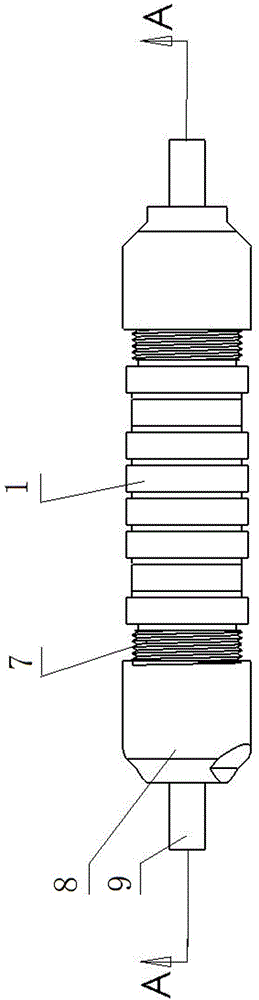

Watertight joint used for butt joint of underwater cables

A technology of watertight joints and underwater cables, which is applied in the direction of cable joints, etc., can solve the problems of performance degradation of underwater cables and threats to the safety of industrial projects, and achieve the effects of convenient maintenance, simple structure and strong pulling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

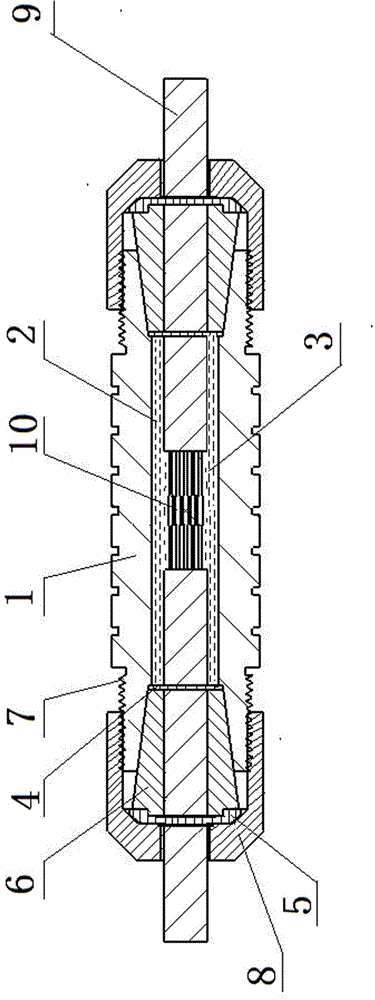

[0016] Example: The process of docking the cables 9 has the following steps: first press all the components figure 2 As shown, the components are respectively placed on the front end parts of the two sections of cables 9 to be connected, and the two cables 9 to be connected are connected to each other, and the connected cable joint 10 is moved into the middle position of the sealing chamber 2; The inner baffle 4, the tapered rubber pad 6, and the outer baffle 5 at one end of the cable joint 10 are pushed into the conical inner chamber of the end of the cylindrical barrel in sequence, and the inner baffle 4, the conical rubber pad 6, and the outer The baffles 5 are all in place, and the compression nut 8 is tightened; the sealant 3 is injected into the sealing cavity 2 from the other end of the joint body 1 of the cylindrical cylinder, and the exposed cable joint 10 is potted; the sealant 3 After solidification, the inner baffle 4, the tapered rubber pad 6 and the outer baff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com