Current sampling circuit with temperature drifting compensation function

A current sampling and acquisition circuit technology, applied in the direction of temperature compensation and modification, can solve the problems of large sampling value, multi-single-chip program space and data space, inaccurate power control, etc., and achieve the effect of accurate power control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

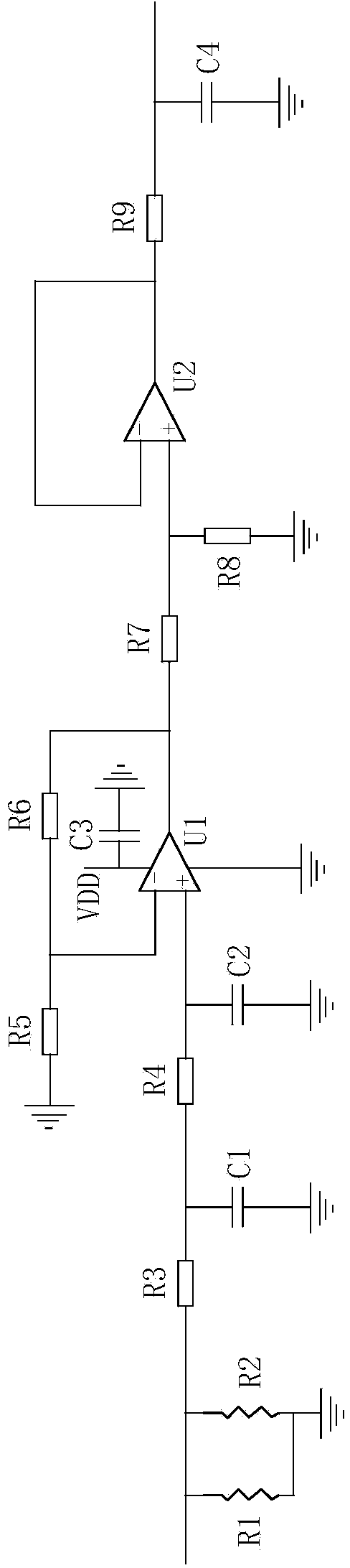

[0021] The present invention will be further described below in conjunction with drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only parts related to the present invention are shown in the drawings but not all content.

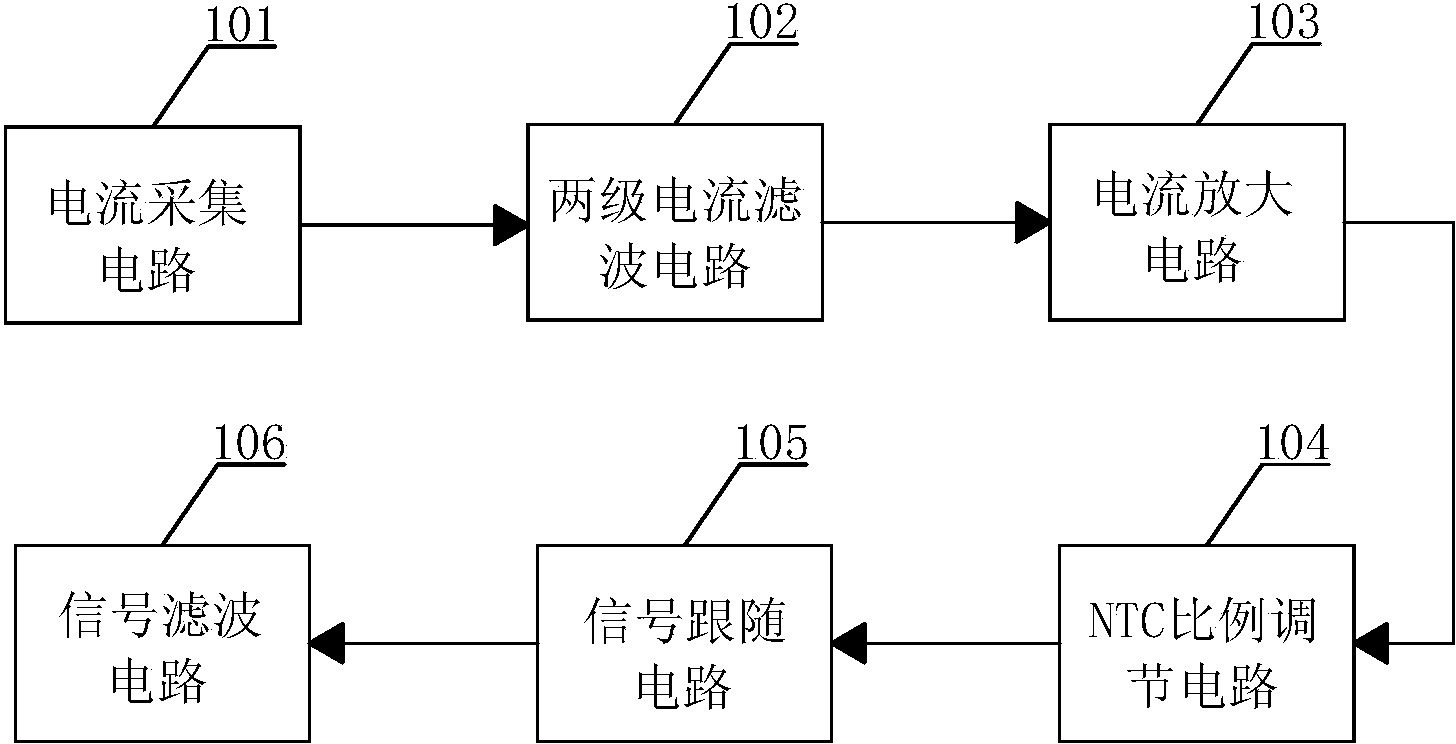

[0022] Please refer to figure 1 as shown, figure 1 A structural block diagram of a current sampling circuit with temperature drift compensation provided by an embodiment of the present invention.

[0023] The current sampling circuit with temperature drift compensation in this embodiment specifically includes: a current acquisition circuit 101 , a two-stage current filter circuit 102 , a current amplification circuit 103 , an NTC ratio adjustment circuit 104 , a signal follower circuit 105 and a signal filter circuit 106 .

[0024] The output end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com