Improved type gas detector

A gas detector, an improved technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems that the gas to be detected cannot be sensed quickly, it is not easy to flow into the gas sensor vertically, and the sensitivity of the gas detector is affected, etc., to achieve rapid Inductive response, high inductive sensitivity, effect of enhanced inductive sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

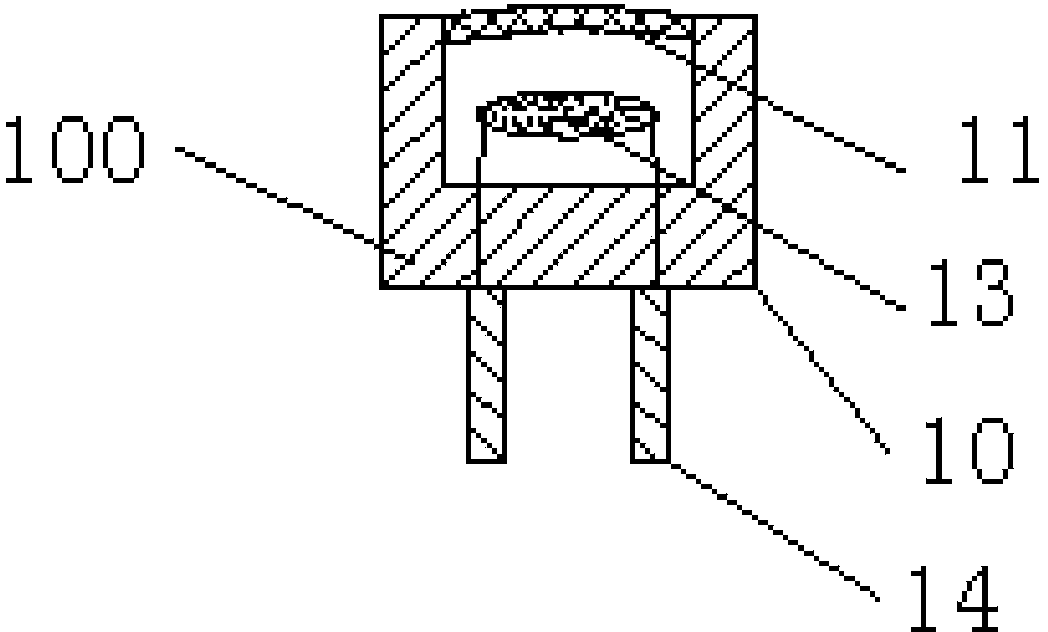

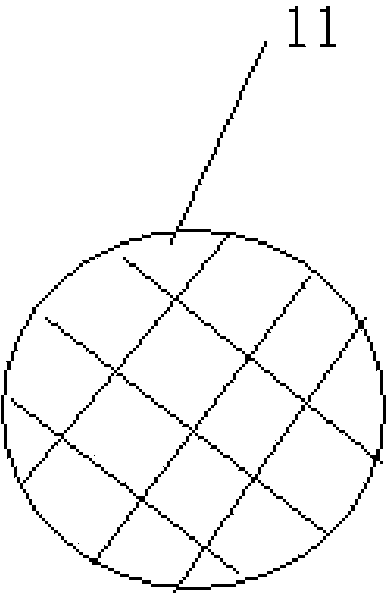

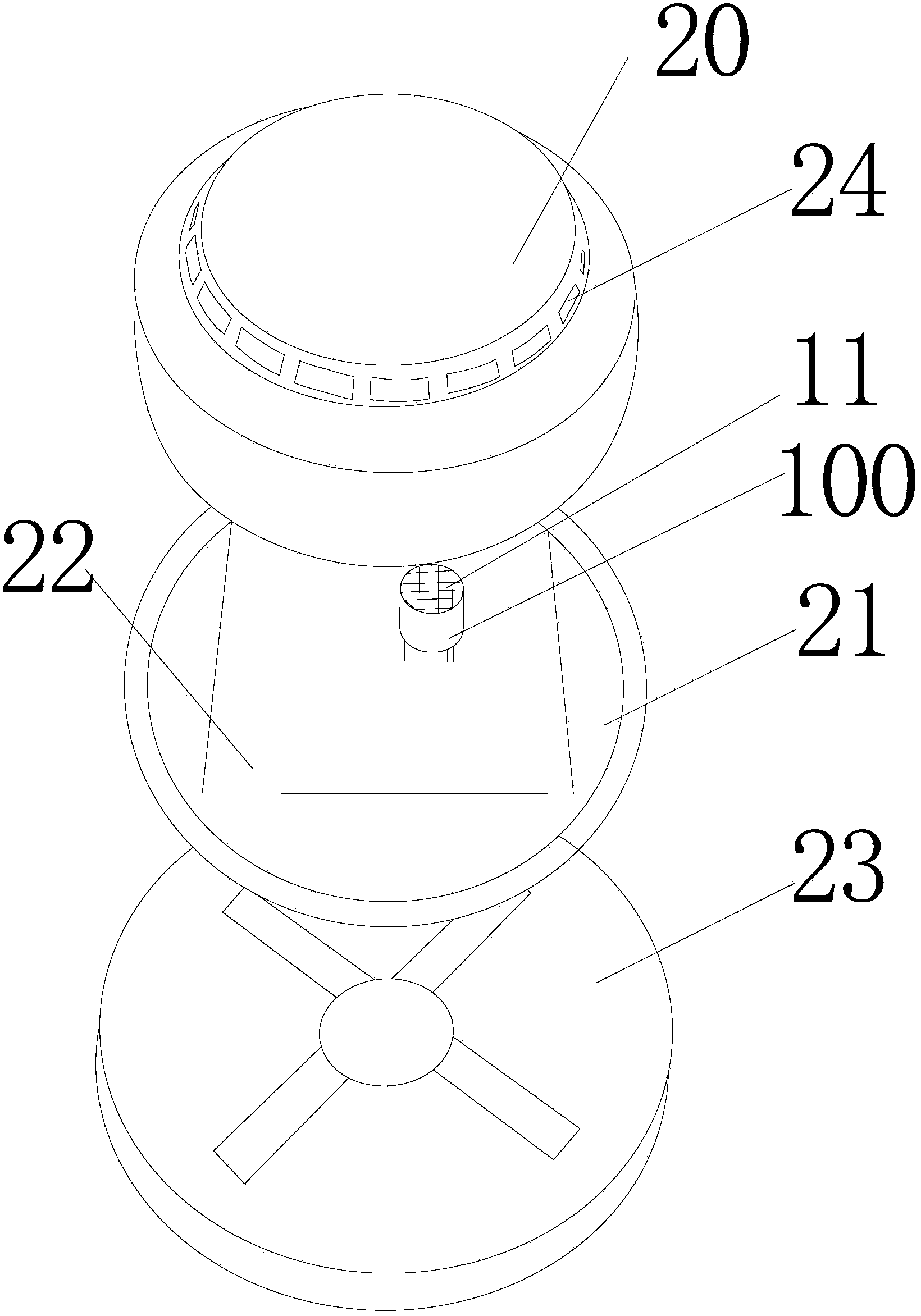

[0031] Embodiment 1 of the present invention provides an improved gas detector, which includes an outer cover 20 from top to bottom (attended Figure 4 ), middle gusset (not shown, same as figure 1 The structure of the prior art in) and the circuit core board ( Figure 4 not shown) and mounting base ( Figure 4 not shown); also includes a gas sensor mounted on the circuit core board of the middle gusset plate, the gas sensor is connected with the integrated circuit on the circuit core board; the diameter of the air inlet window at the top of the gas sensor is d; the outer cover is provided with a plurality of outer cover windows along the circumferential direction of the outer cover wall (the main improvement structure of the improved gas detector provided by the embodiment of the present invention is the improvement of the outer cover 20, and its inner bottom surface contains a plurality of V Shaped flow-guiding baffles constitute structural components, and the middle gusse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Opening width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com