A Deformation Measurement Method of Tensile Specimen Based on Digital Image Correlation

A technique for tensile specimens and measurement methods, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of decreased tracking accuracy, image interference, deformation of marking points, etc., so as to improve the measurement speed and accuracy, and avoid sample marking. , The effect of simplifying the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

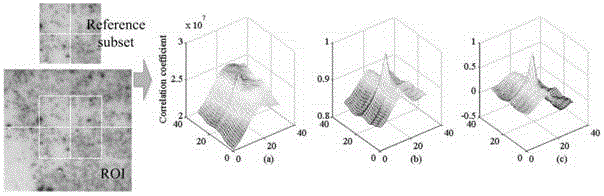

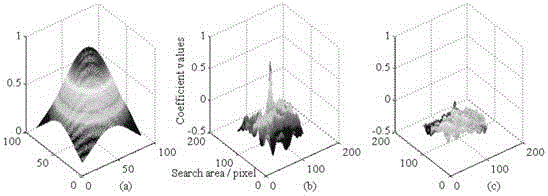

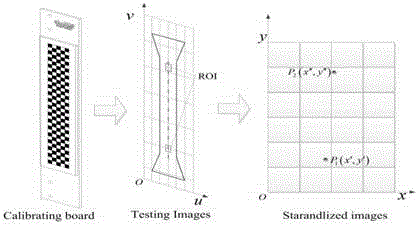

[0029] The digital image correlation-based tensile sample deformation measurement method of the present invention, in the video extensometer, in order to realize the high-speed precision measurement of the tensile sample deformation and simplify the previous sample marking method, the present invention focuses on using the image correlation method, combined with The measurement method based on the reference plane realizes the high-speed and high-precision measurement of the sample. It overcomes the shortcoming that the overall measurement accuracy of the system is limited in the traditional video extensometer measurement method. Such as figure 1 As shown, the algorithm implementation of this method is mainly divided into three parts, 1. Integer pixel positioning based on image correlation; 2. Sub-pixel positioning based on two-dimensional surface fitting; 3. Image mapping positioning based on reference plane. The organic combination of the three constitutes the main body of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com