Reticle increment calibration method for laser galvanometer system

A technology of laser galvanometer and calibration method, which is applied in the direction of measuring device, optical instrument test, machine/structural component test, etc. Accuracy and other issues to achieve the effect of reducing workload and reducing the impact of human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0022] A crosshair incremental calibration method for a laser galvanometer system, comprising the following steps:

[0023] 1) First, open the calibration software and related files on the industrial computer of the laser galvanometer system that needs to be calibrated;

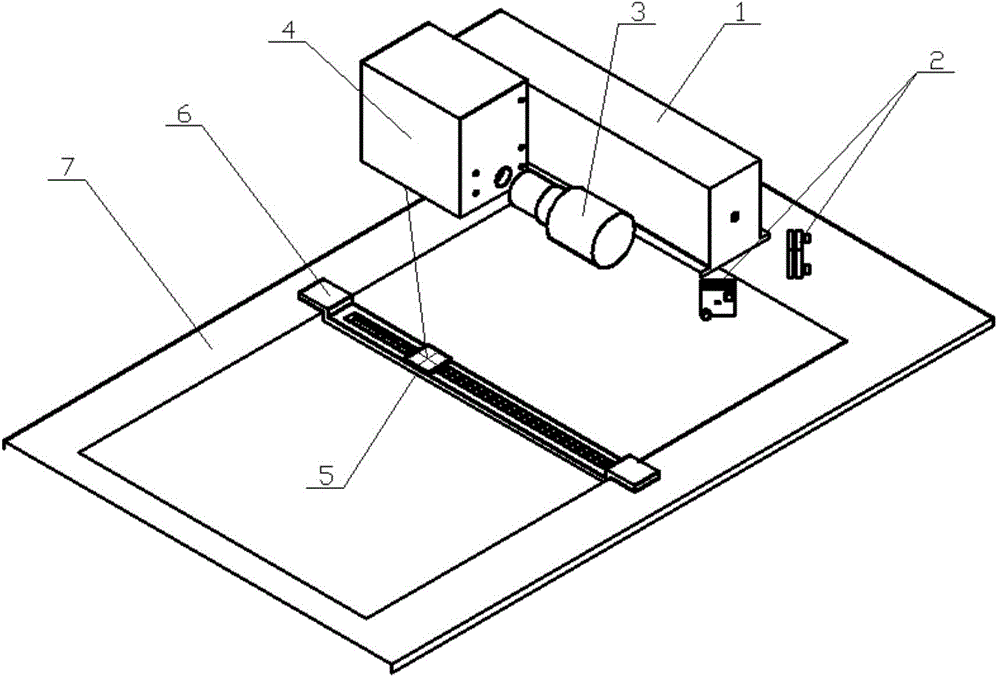

[0024] 2) Refer to figure 1 , turn on the power of the laser 1 to make it emit a laser beam, the laser beam enters the dynamic focus mirror 3 after being reflected by two reflectors 2, and then enters the scanning galvanometer system 4, adjusts the reflector 2, the dynamic focus mirror 3 and the scanning The installation position of the galvanometer system 4 enables the laser beam to be ideally focused on the plane 7;

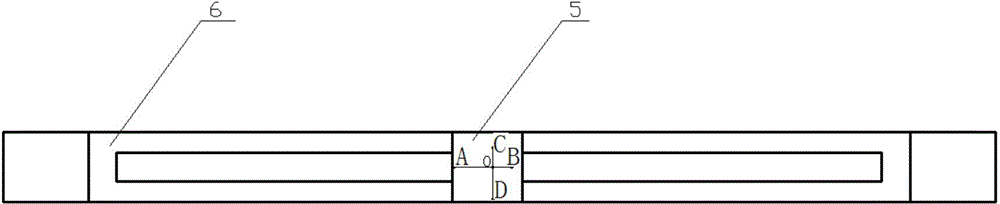

[0025] 3) Install the calibration device support frame 6 and the optical sensor 5 on the plane 7, and use gaskets to repeatedly adjust the height of the calibration device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com