Inflating device with air storage barrel

A technology of air storage barrels and cylinders, which is applied in the direction of pump devices, liquid variable-capacity machines, variable-capacity pump components, etc., and can solve problems such as overall operation troubles, time-wasting, and inaccurate handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

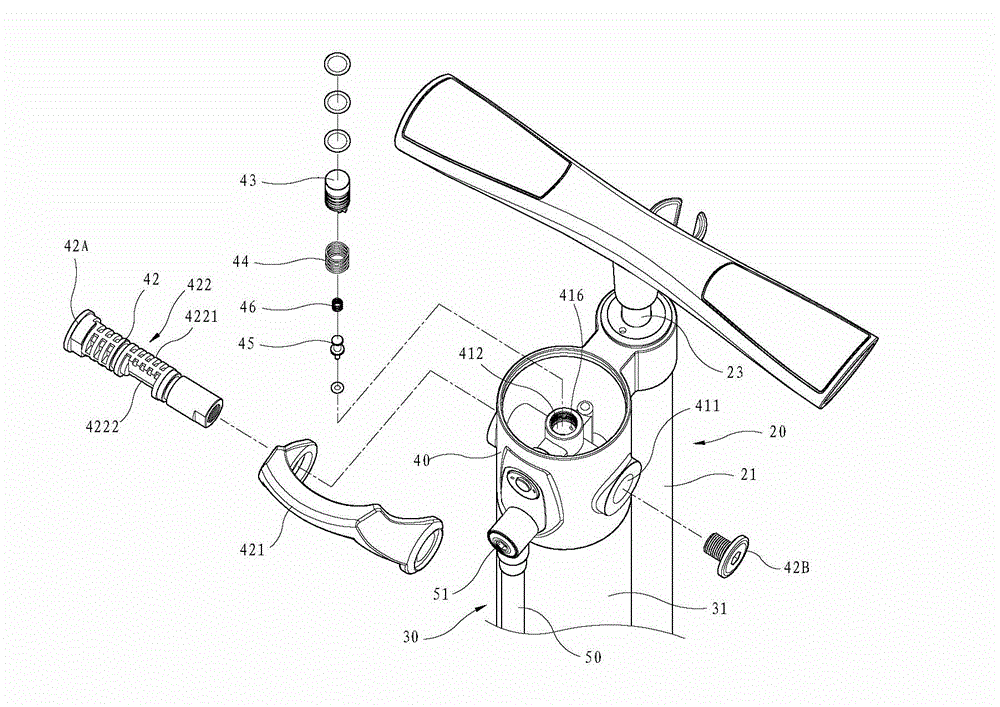

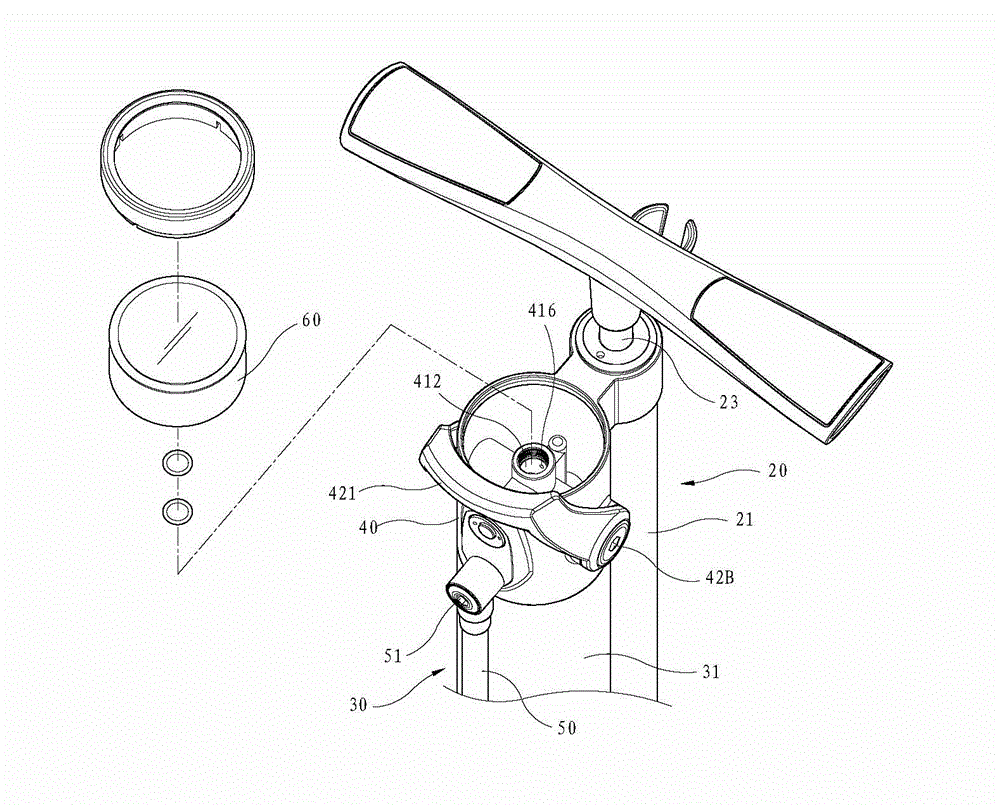

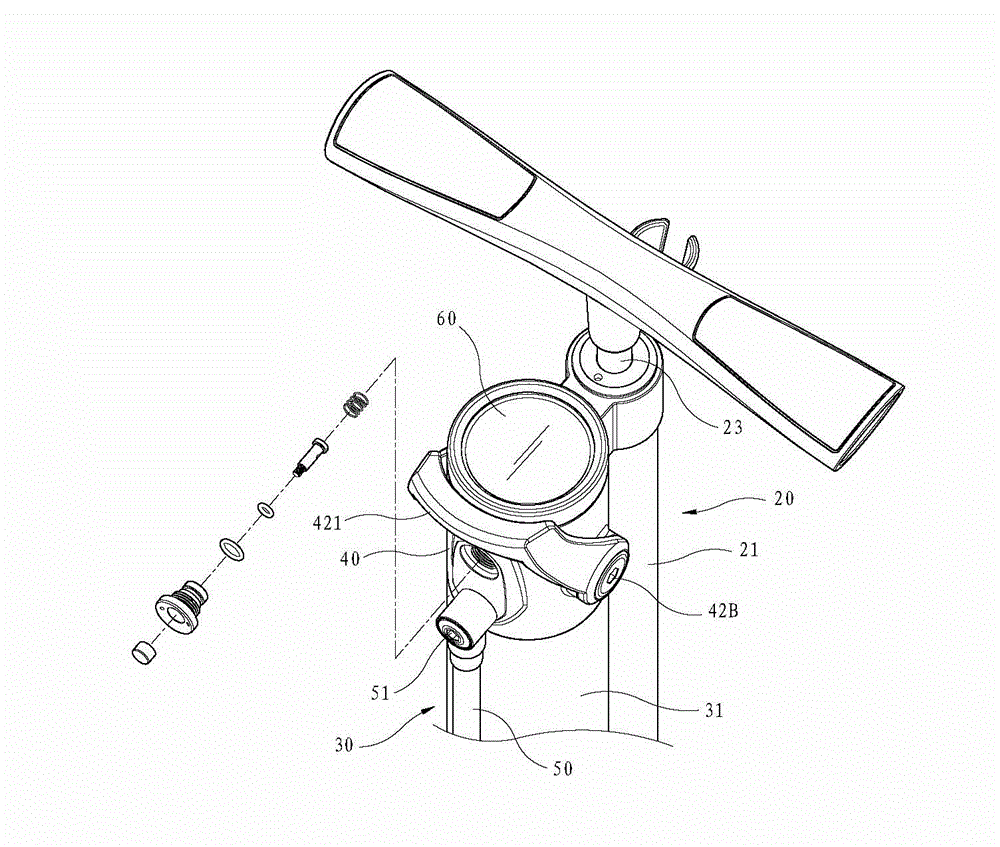

[0060] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

[0061] Please refer to Figure 1 to Figure 8 , the present invention includes:

[0062] A carrier 10, which is provided with a U-shaped approach 11 communicating with the inside and outside, and a socket 12 is provided at one end of the opposite approach 11, and a one-way valve 13 is installed;

[0063] An inflating device 20 has a hollow cylinder 21, the bottom of which is fixed to the socket 12 of the carrier 10, and a piston 22 is slidably arranged in the cylinder 21, which can be driven by a linkage rod 23 to move in the cylinder. Agitate the gas in 21, so that the pressurized gas can enter the approach 11 through the one-way valve 13;

[0064] A gas storage barrel 30, which has a barrel body 31 whose bottom end is airtightly fixed on the stage 10, a top plate 32 that closes the top edge of the barrel bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com