Adjustable device for temporarily stabilizing the material to be cut on the cutting table

A cutting material, adjustable technology, applied in fur cutting, application, leather punching/punching/cutting, etc., can solve problems such as increased production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

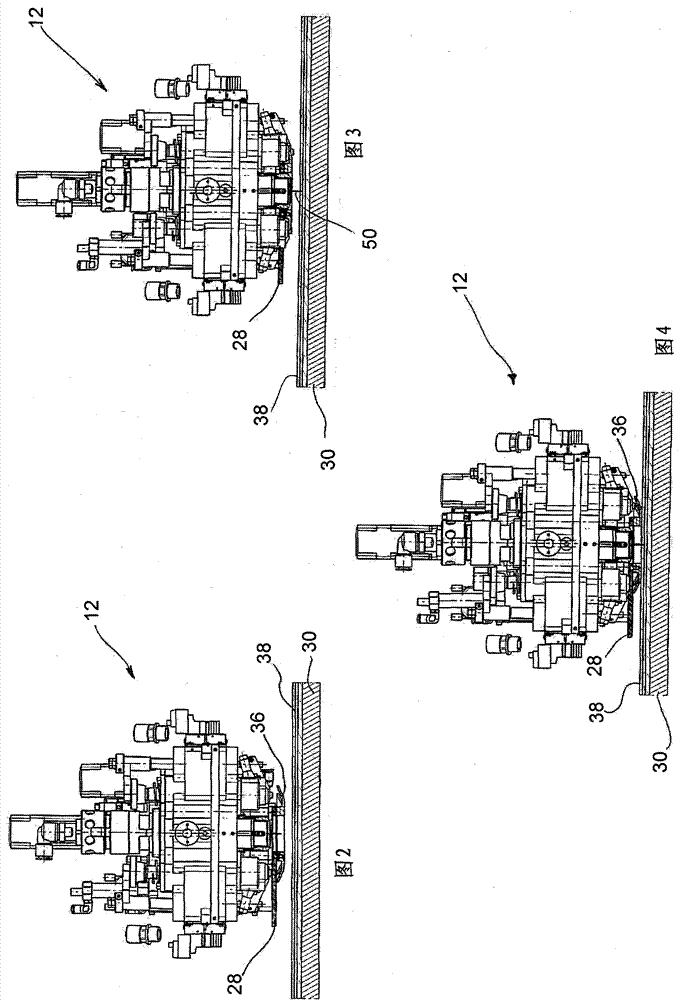

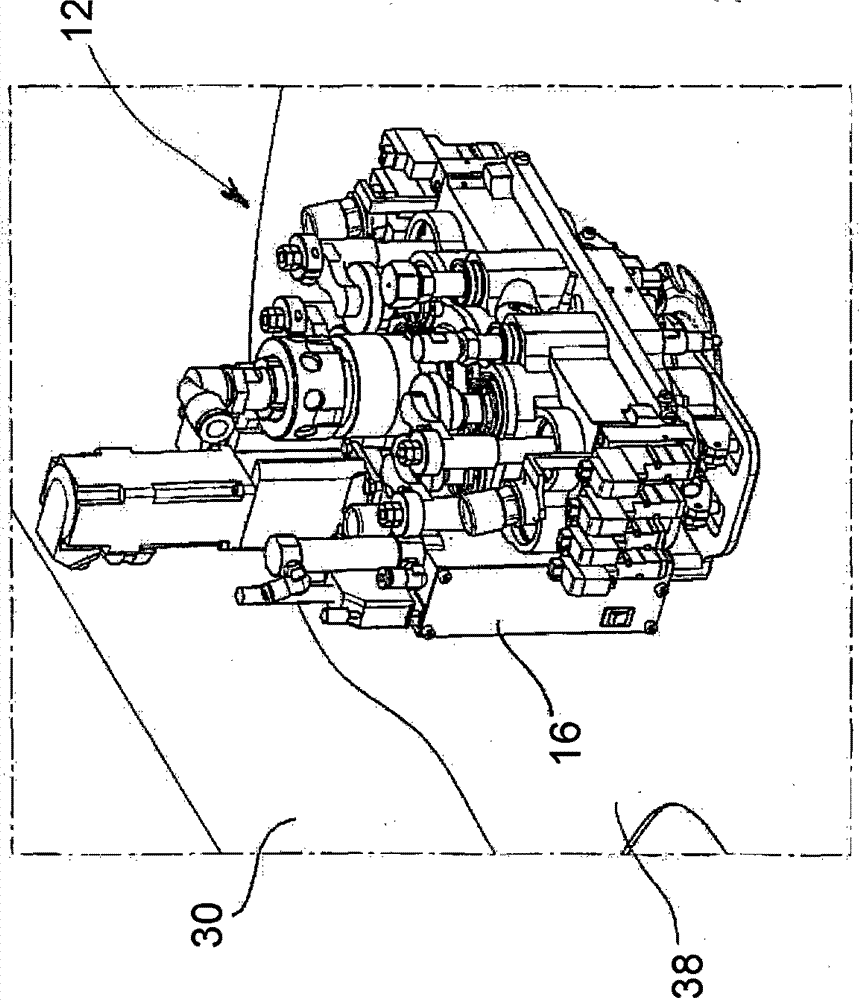

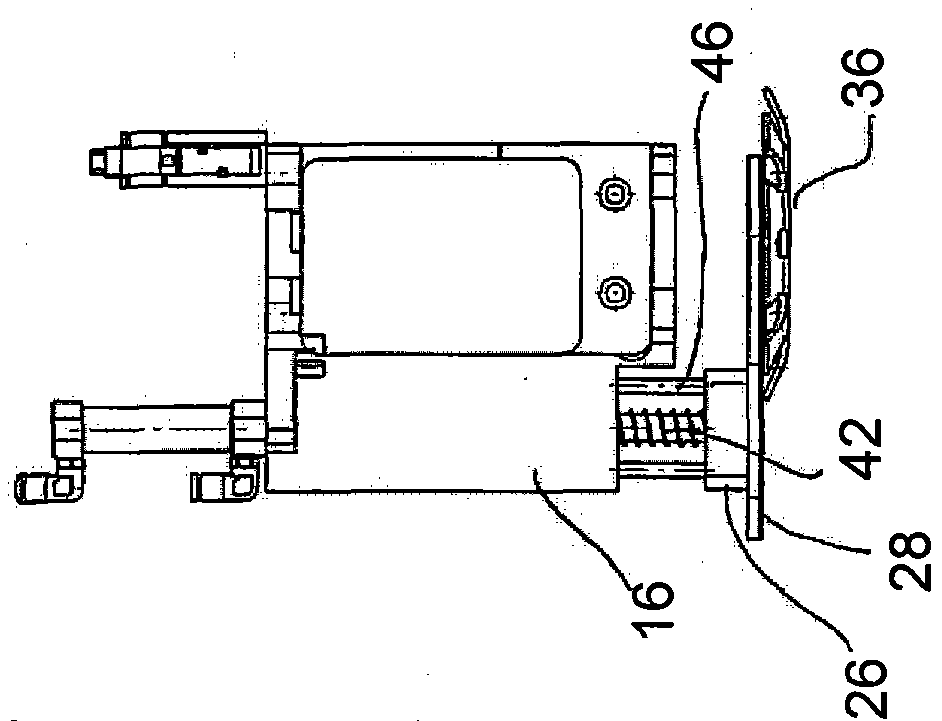

[0022] first reference figure 1 with Image 6 , an adjustable device for temporarily stabilizing the material to be cut on the cutting table Image 6 The reference number 10 in indicates that the device is combined with a cutting unit known per se, which is in figure 1 Indicated by reference numeral 12. The device 10 comprises a frame 14 carrying a pneumatic cylinder 18 or equivalent within a housing 16, in Figure 7 with Figure 8 are shown in more detail. Said pneumatic cylinder is combined with a double-acting solenoid valve 20 which produces movement and causes the cylinder rod 22 to rise and fall. The cylinder rod 22 is integral with a shaft 24, the lower end of which (lower end) engages a substantially annular body 26; the latter constitutes a support for a plate 28 projecting from the frame 14 and extending parallel to the working surface of the cutting table. face extension, in figure 1 , Figure 7 with Figure 8 The middle working surface is indicated by refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com