Rotary single-arm crane

A rotary, single-arm technology, applied in the direction of load hanging components, track systems, cranes, etc., can solve the problems of long driving distance, low work efficiency, and small number of driving, and achieve high speed, reduce labor intensity, and short travel Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

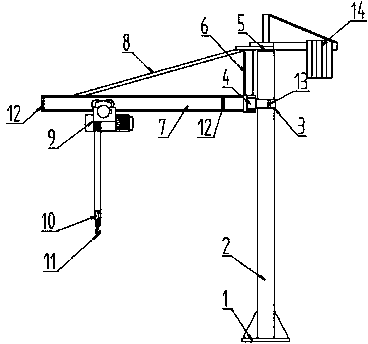

[0012] Such as figure 1 As shown, the present invention relates to a rotary single-arm crane, which is provided with a base 1, a column 2, a rotating shaft 5, a raceway 3, a support roller 4, a support plate 6, a beam 7, a tie bar 8, an electric hoist 9, and a pulley 10. The hook 11 and the counterweight iron 14 are characterized in that the base 1 and the lower end of the column 2 are welded together, the base 1 is fixed on the ground by bolts, the upper end of the support plate 6 is fixed with the rotating shaft 5, and the lower end is equipped with The support roller 4, the support roller 4 is installed on the raceway 3 and rolls around the column 2, the raceway 3 is fixed on the column 2, the end of the beam 7 close to the column 2 is welded on the support plate 6, and the other end is connected to the support plate through the tie bar 8 The upper ends of 6 are connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com