Automobile skylight pressurized sealing system

A technology for automobile sunroof and air pressure sealing, which is applied to sealing devices, engine sealing, vehicle components, etc., can solve the problems of large opening and closing resistance, tearing, poor sealing effect, etc., and achieve the effect of small opening and closing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

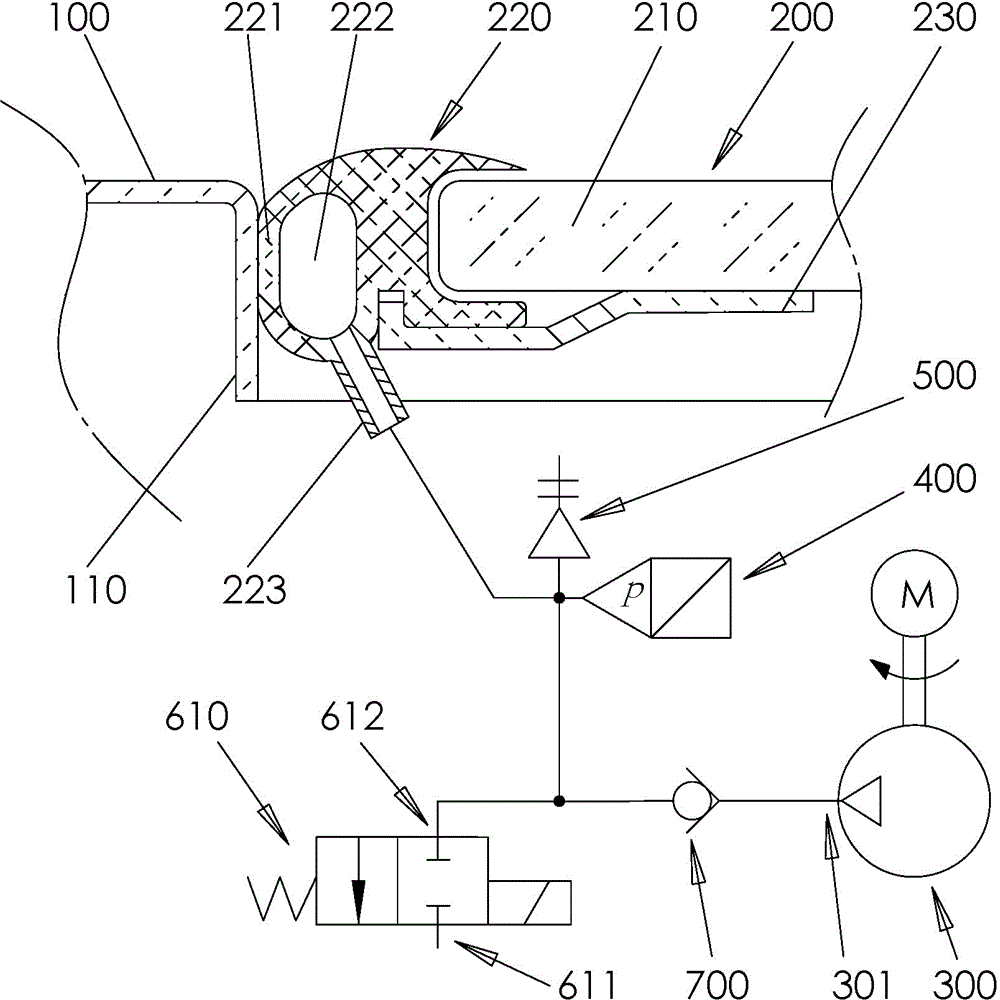

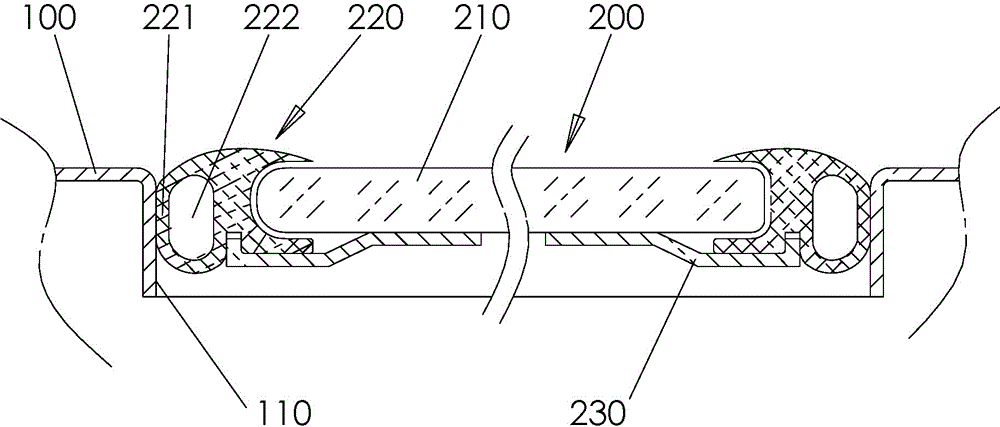

[0035] figure 1 It is Embodiment 1 of the present invention. This example automobile sunroof air pressure sealing system includes a car roof 100, a flange 110 around the sunroof opening, a sunroof glass assembly 200, a pressure sensor 400, a safety valve 500 and an air charging and discharging device. The sunroof glass assembly 200 includes a sunroof glass 210 and a sealing ring 220. The sealing ring 220 surrounds and is fixed on the edge of the sunroof glass 210 and is in an annular closed state. The sealing ring 220 is provided with a cavity 222 inside. There is an interface 223 communicating with the cavity 222; the air charging and discharging device can be installed on the skylight glass support plate 230 of the skylight glass assembly 200, and the air charging and discharging device in this example includes an electric air pump 300 and a one-way valve 700 , Two-position two-way solenoid valve 610, the electric air pump 300 is a speed type air pump, the air outlet 301 of ...

Embodiment 2

[0037] figure 2 It is embodiment 2 of the present invention, except that the air charging and discharging device is different from embodiment 1 in this embodiment, the rest is the same as embodiment 1, which can be directly quoted and will not be repeated here; the air in this embodiment The charging and discharging device includes an electric air pump 300 and a three-position three-way solenoid valve 620. The air outlet 301 of the air pump 300 is connected to the P port 622 of the three-position three-way solenoid valve 620, and the A port 621 of the three-position three-way solenoid valve 620 is connected to The interface 223 of the sealing ring 220 is connected, and the T port 623 of the three-position three-way solenoid valve 620 and the air inlet of the air pump 300 are communicated with the atmosphere; When the spool is at the right position, the T port 623 communicates with the A port 621, and the compressed air in the sealing ring 220 can be discharged into the atmosp...

Embodiment 3

[0038] image 3 It is the embodiment 3 of the present invention, except that the air charging and discharging device is different from the embodiment 1 in the present embodiment, the remaining parts are the same as the embodiment 1, which can be directly quoted and will not be repeated here; the air in this embodiment The charging and discharging device includes an electric air pump 300 and a three-position four-way solenoid valve 630. The air outlet 301 of the air pump 300 is connected to the P port 632 of the three-position four-way solenoid valve 630, and the A port 631 of the three-position four-way solenoid valve 630 is connected to The interface 223 of the sealing ring 220 is connected, the T port 633 of the three-position four-way solenoid valve 630 is connected with the air inlet 302 of the air pump 300, and the B port 634 of the three-position four-way solenoid valve 630 is communicated with the atmosphere; Or when closing the car sunroof, put the spool of the three-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com