Method for pasting on side of light-leaking prevention paster of light guide plate

A light guide plate, anti-light leakage technology, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve problems such as excessively long steps, reduced adhesion, and inability to effectively control the quality of pasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

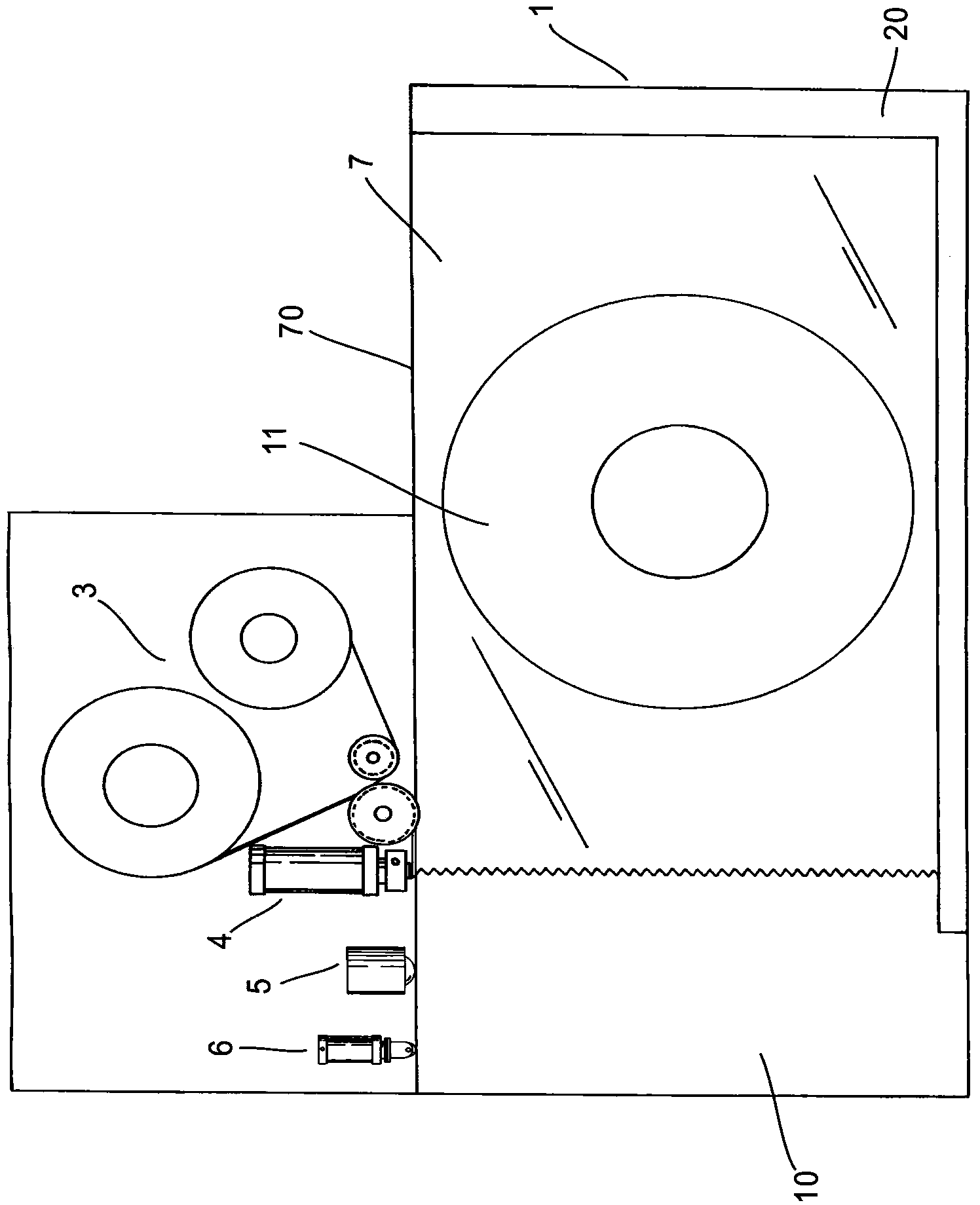

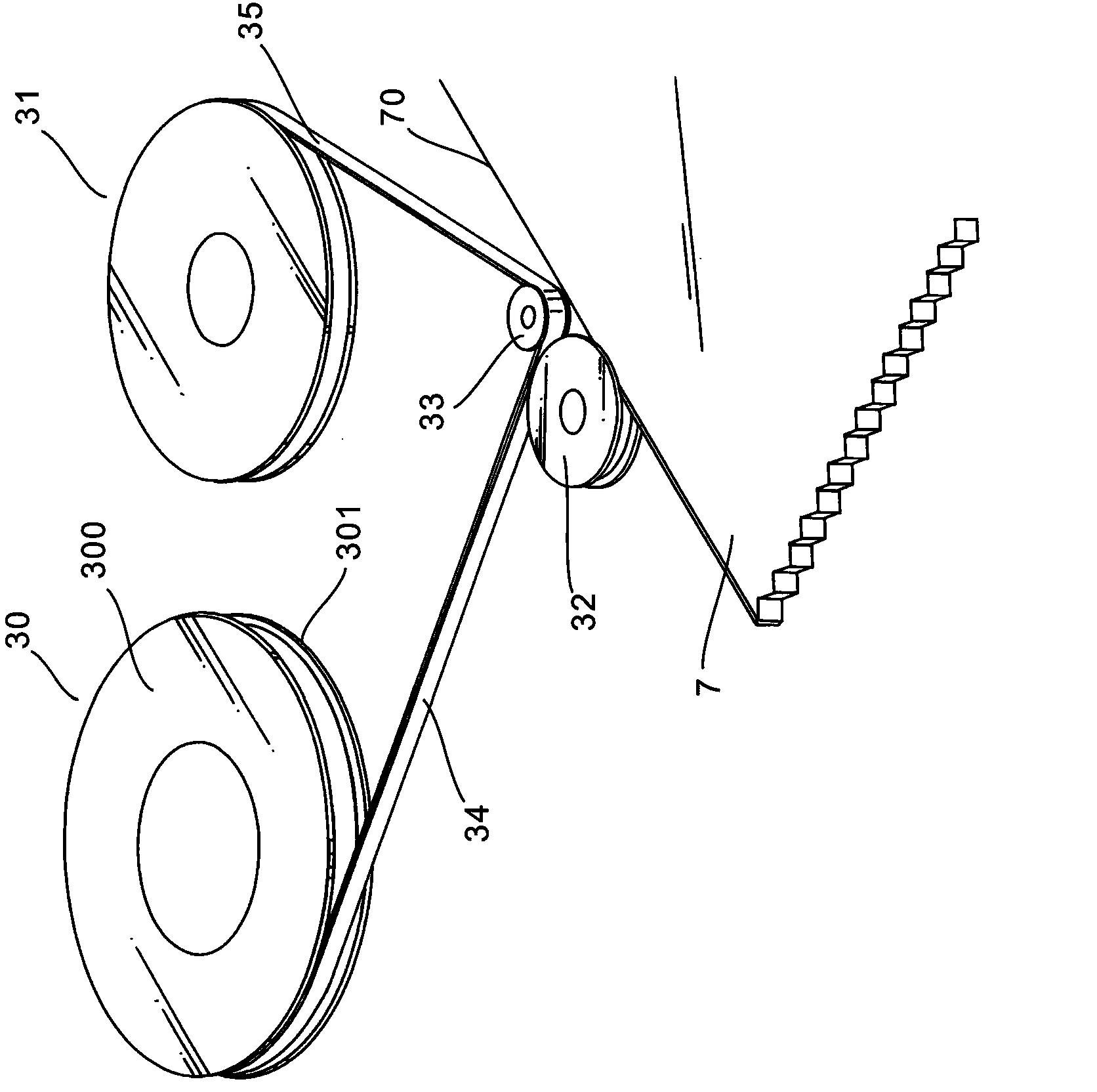

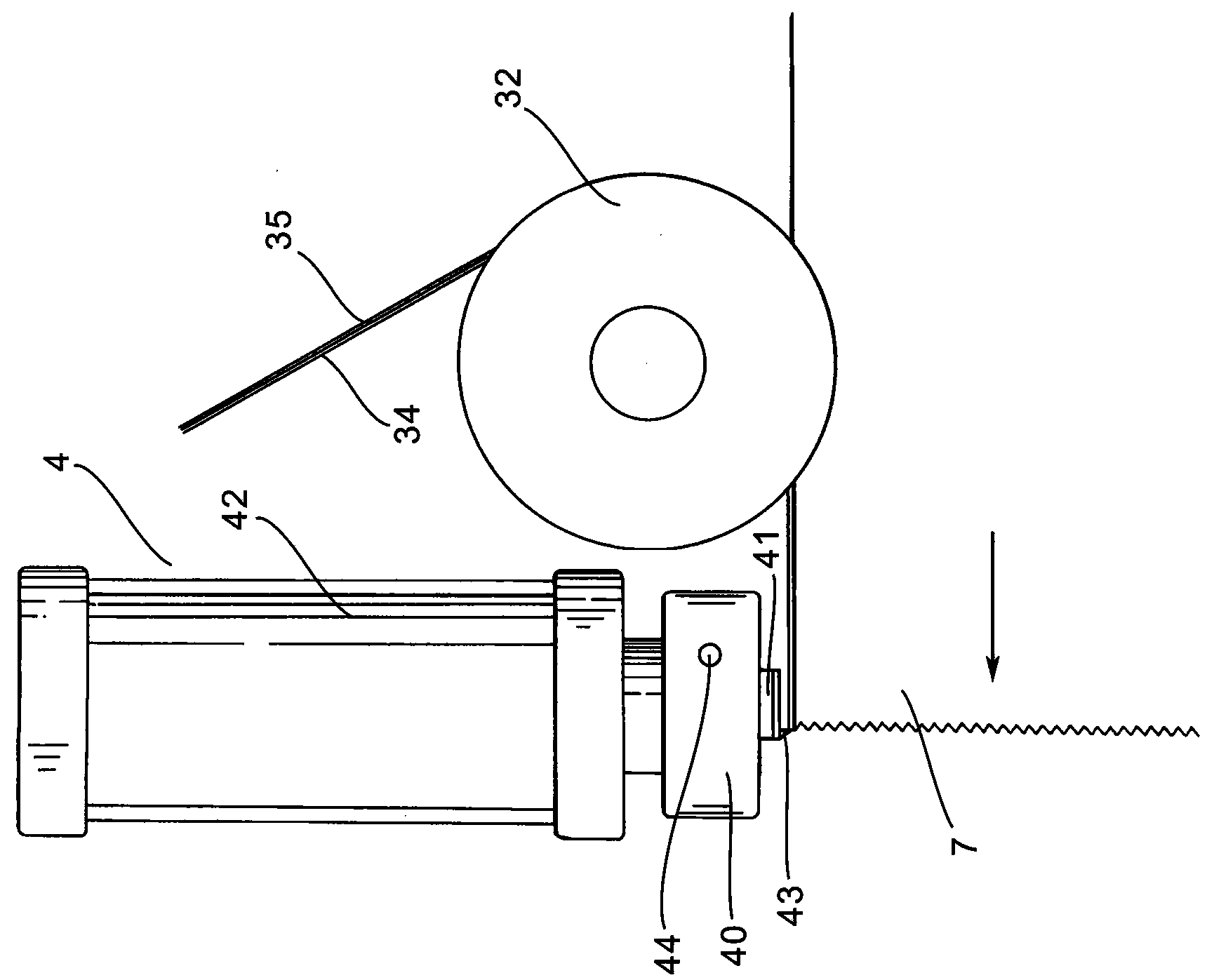

[0025] refer to figure 1 As shown, the light guide plate anti-leakage sticker side-attaching equipment used in the method for attaching the light guide plate anti-leakage sticker to the side of the present invention mainly includes a platform mechanism 1, a retaining device 2, a separation device 3, an alignment cutting device 4, and a pressing and sticking device 5 and leveling device 6; wherein the platform mechanism (such as figure 1 ) cooperate with a platform, the platform includes a transport base 10, on which a retaining device 2 is arranged, and the retaining device 2 has an L-shaped reference frame 20 for positioning and aligning the light guide plate 7, so that The side end surface 70 of the light guide plate 7 is accurately aligned with each device, and then pressed down with the positioning plate group 11; and the separating device 3 (such as figure 2 (shown) includes a sticker wheel 30, a delivery wheel 31 and two tear-off rollers 32, 33, wherein the sticker whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com