System and method for manufacturing honeycomb body

A honeycomb body and equipment technology, applied in chemical instruments and methods, driving devices for metal rolling mills, mechanical equipment, etc., can solve problems such as high cost, inaccurate honeycomb body shape, and insufficient honeycomb body performance, and achieve precise rolling winding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

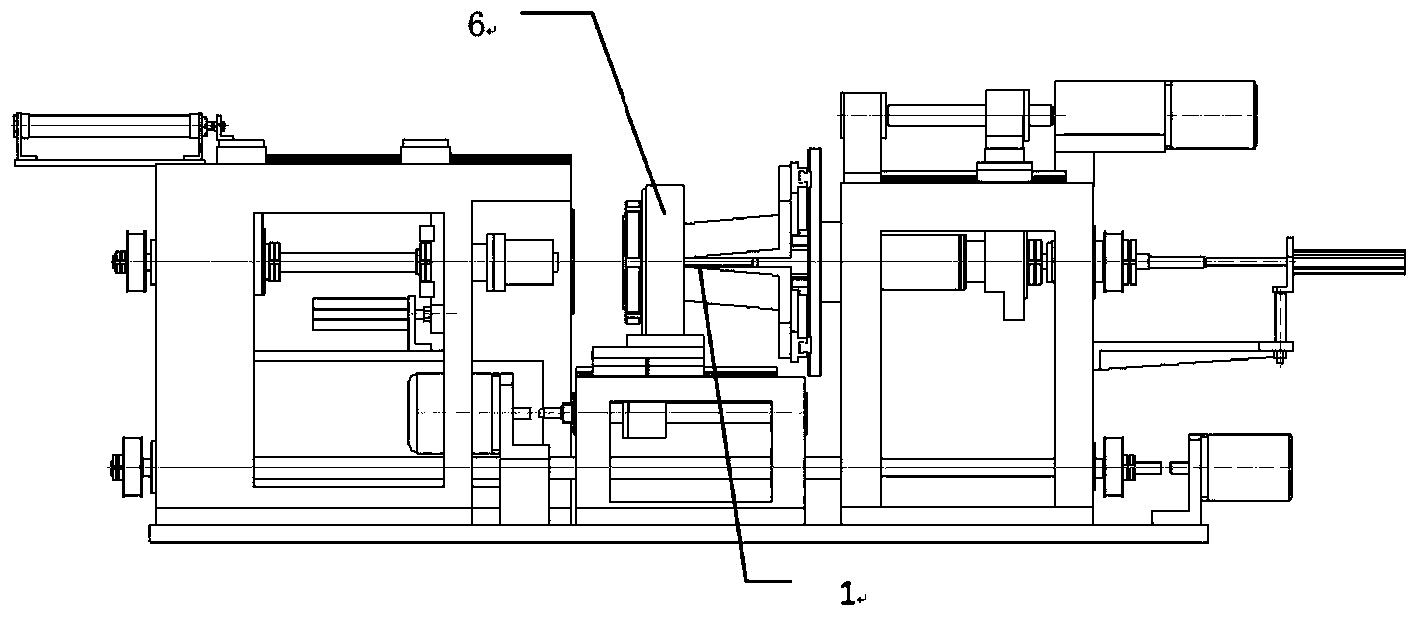

[0030] figure 1 An apparatus for rolling a honeycomb body according to the invention is shown. The equipment includes a frame, a transmission system, and a forming die 1 and a tightening die 6 for roll-forming the honeycomb body.

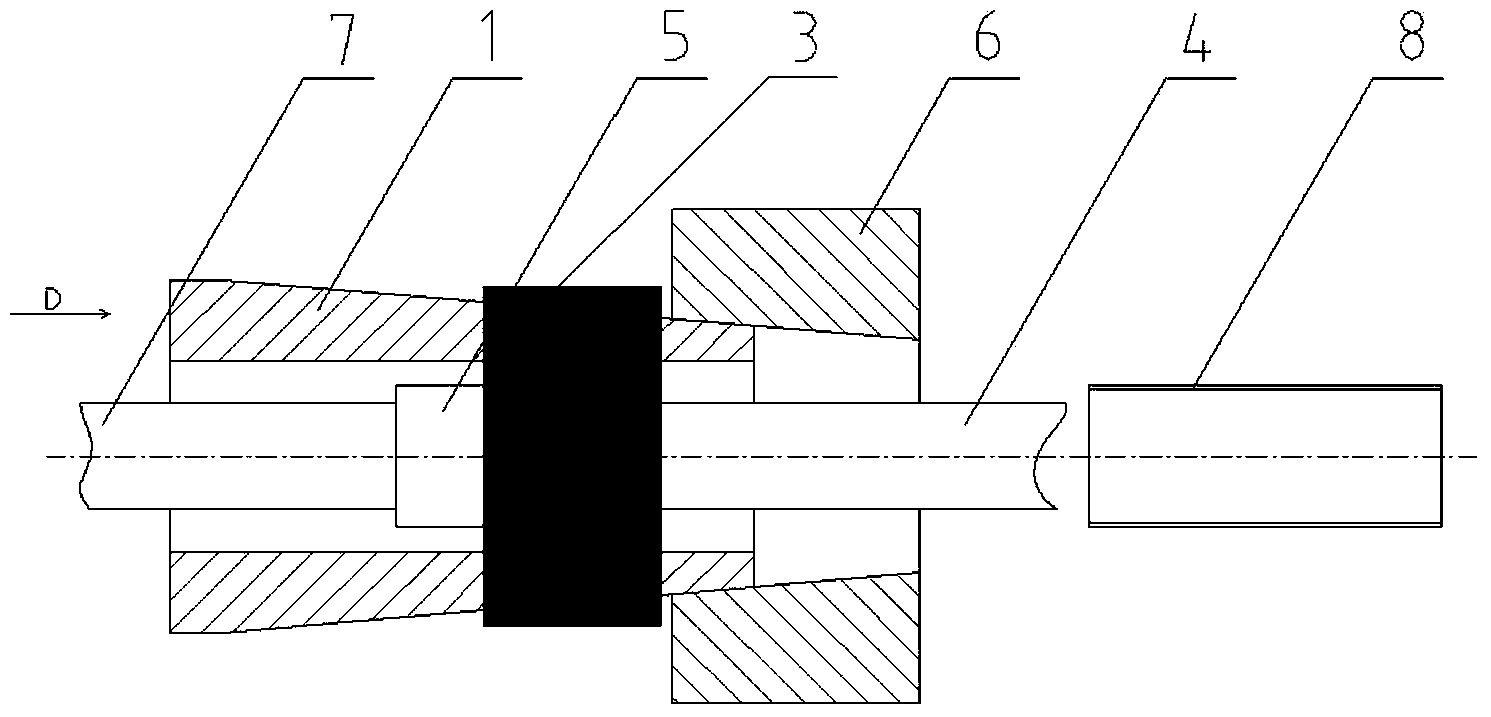

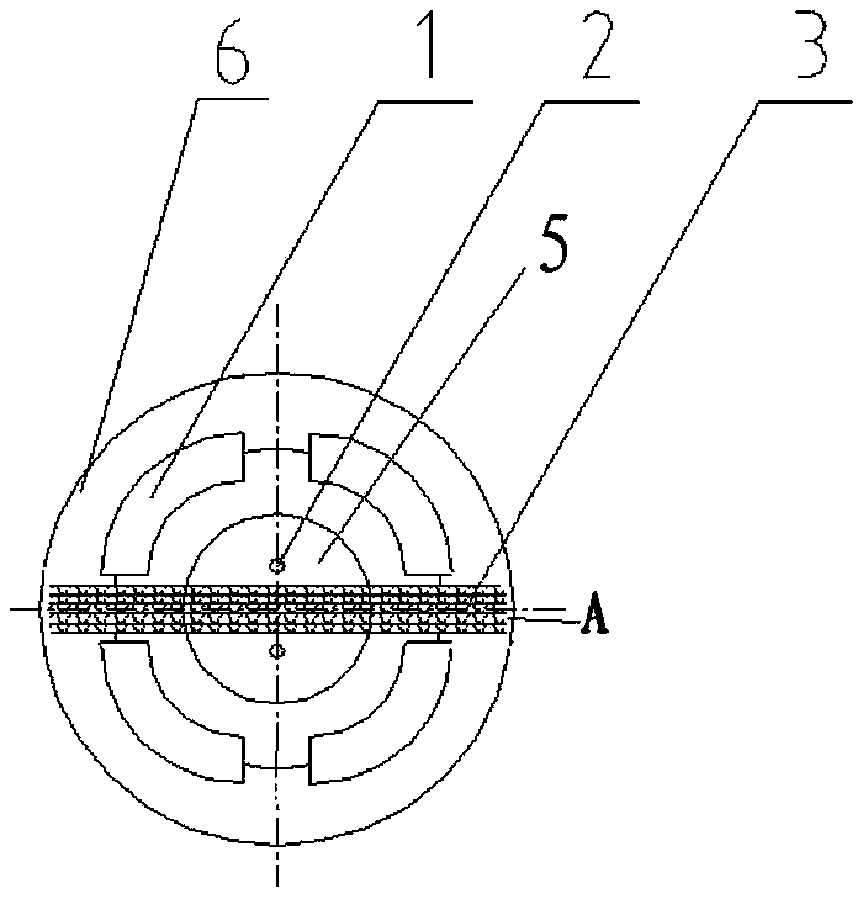

[0031] figure 2 and 3 A detail of an apparatus according to the invention for rolling a honeycomb body is shown. Forming mold 1 comprises four parting molds (see image 3 ), these four parts can be opened and closed. For example, the four parting molds are supported on the frame like four jaws of a four-jaw chuck. Preferably, each parting mold can slide radially in its own slideway. They are biased towards opening by elastic members. Of course, it is also feasible to arrange the parting molds in other known ways.

[0032] Depend on image 3 It can be seen that in the opened state of the forming die 1, there is a gap A between the four parting dies, through which the corrugated belt and flat belt assembly 3 to be rolled can be sent into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com