Continuous conveyor for transporting heavy bulk material or articles

A technology for conveyors and goods, applied in the direction of conveyors, synchronous motors for single-phase current, conveyor objects, etc., can solve the problem of high cost, and achieve the effect of eliminating deformation or even breakage, reducing load, and small impact torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

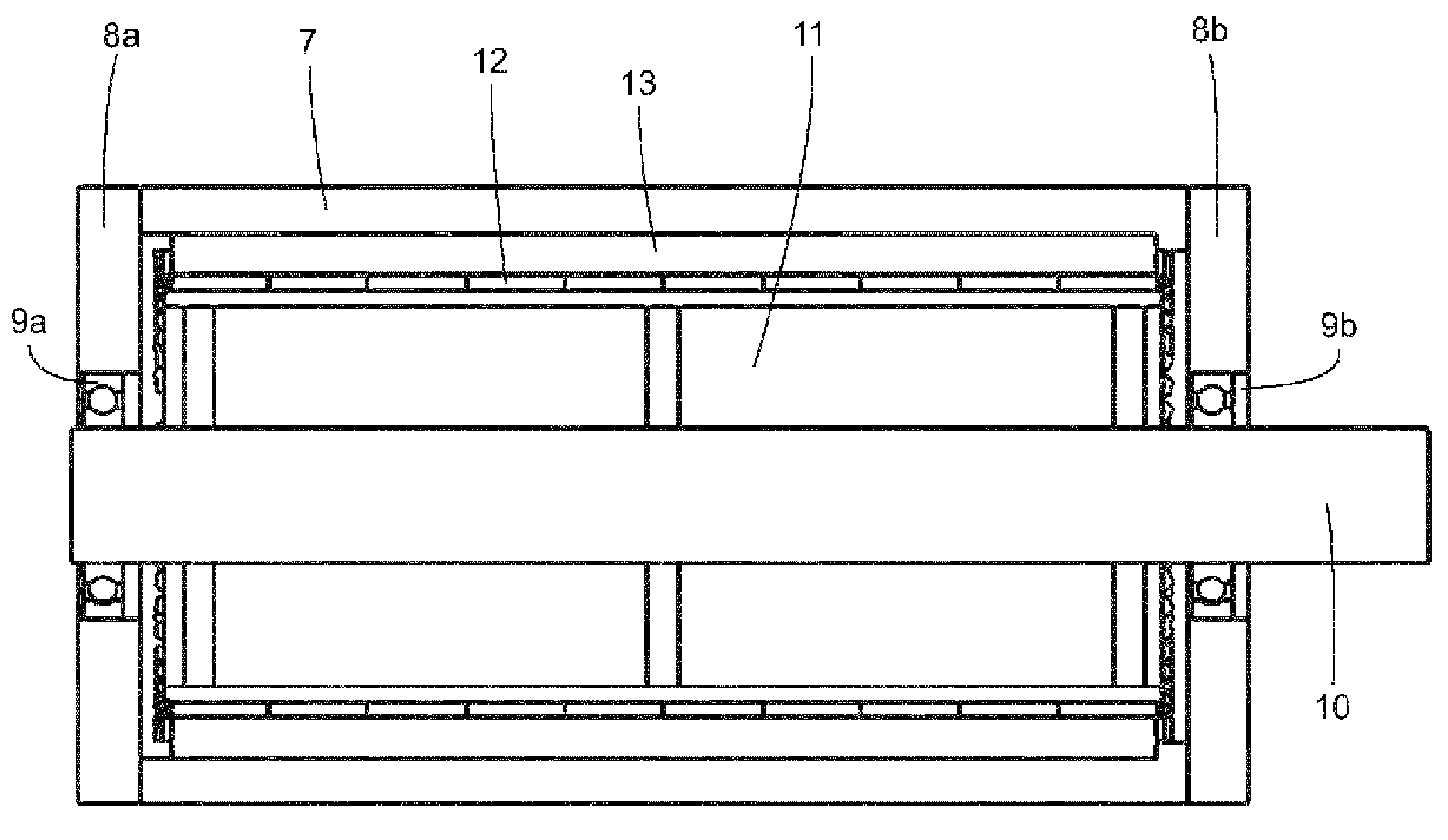

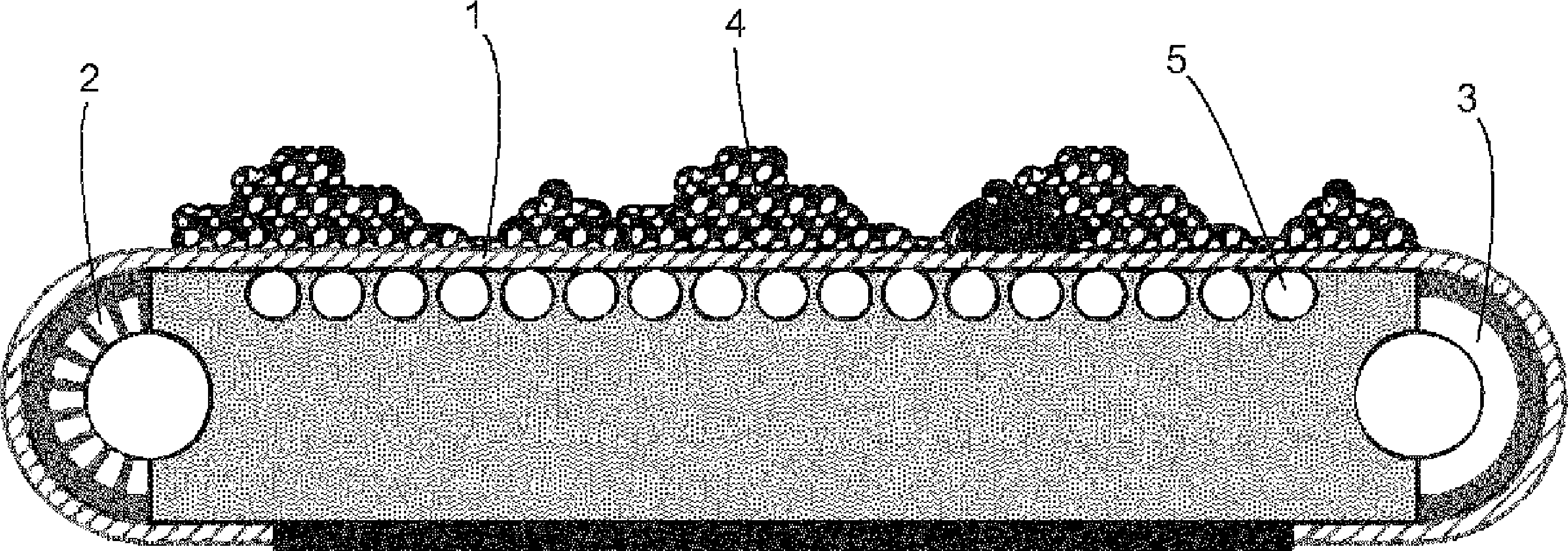

[0022] exist figure 1 A conveyor belt is schematically shown as an example of a continuous conveyor in . Its endless conveyor belt 1 runs in a loop between drive rollers 2 and guide rollers 3 . Heavy bulk goods 4 , such as ore or crushed rock, are delivered to the part of the conveyor belt 1 that just forms the upper run and are conveyed substantially horizontally from left to right in the drawing. Below the conveyor belt 1 are arranged idler rollers 5 which support the weight of the conveyor belt 1 and the bulk goods 4 .

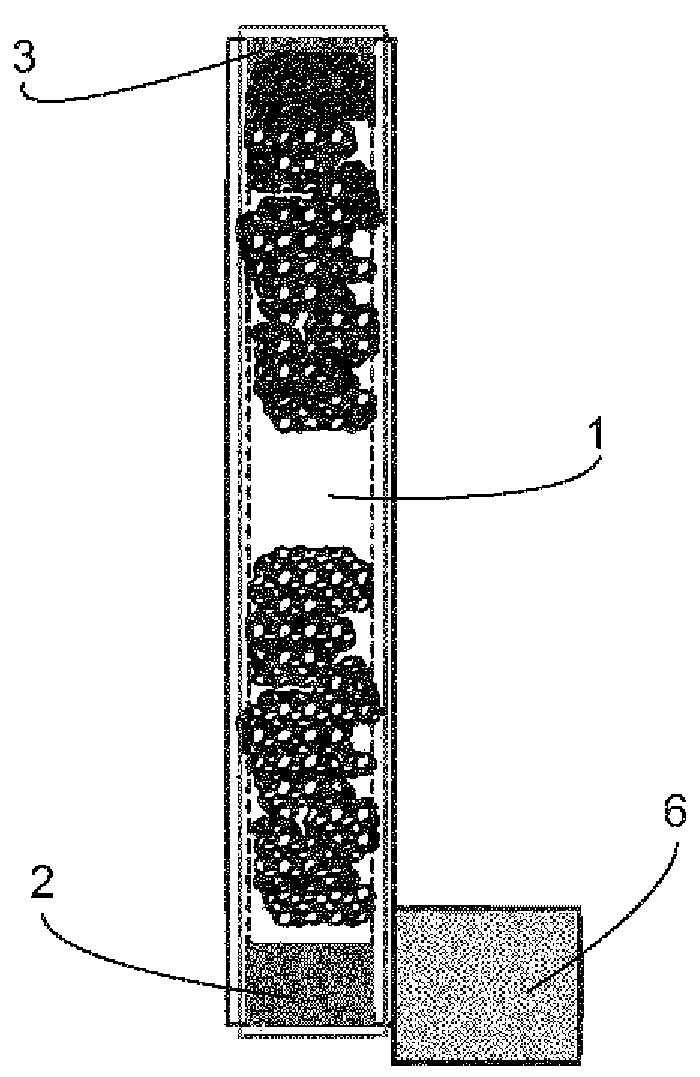

[0023] The conveyor belt is driven with a high torque by a slow-running multi-pole synchronous motor 6 . if available at figure 2 As can be seen in , the synchronous motor 6 directly drives the drive roller 2 of the conveyor belt, ie there is no intervening mechanical transmission. The operating speed of the drive roller 2 is approximately 40 U / min, so that the synchronous motor 6 also has a rated speed of 40 U / min. The synchronous motor 6 delivers a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com