A fixing device for connecting the grounding wire of the secondary terminal port of the high-voltage transformer

A high-voltage transformer and secondary terminal technology, which is applied in the direction of connection, conductive connection, electrical component connection, etc., can solve the problem of small size, achieve small structure size, reduce the probability of damage, and save installation and fixing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

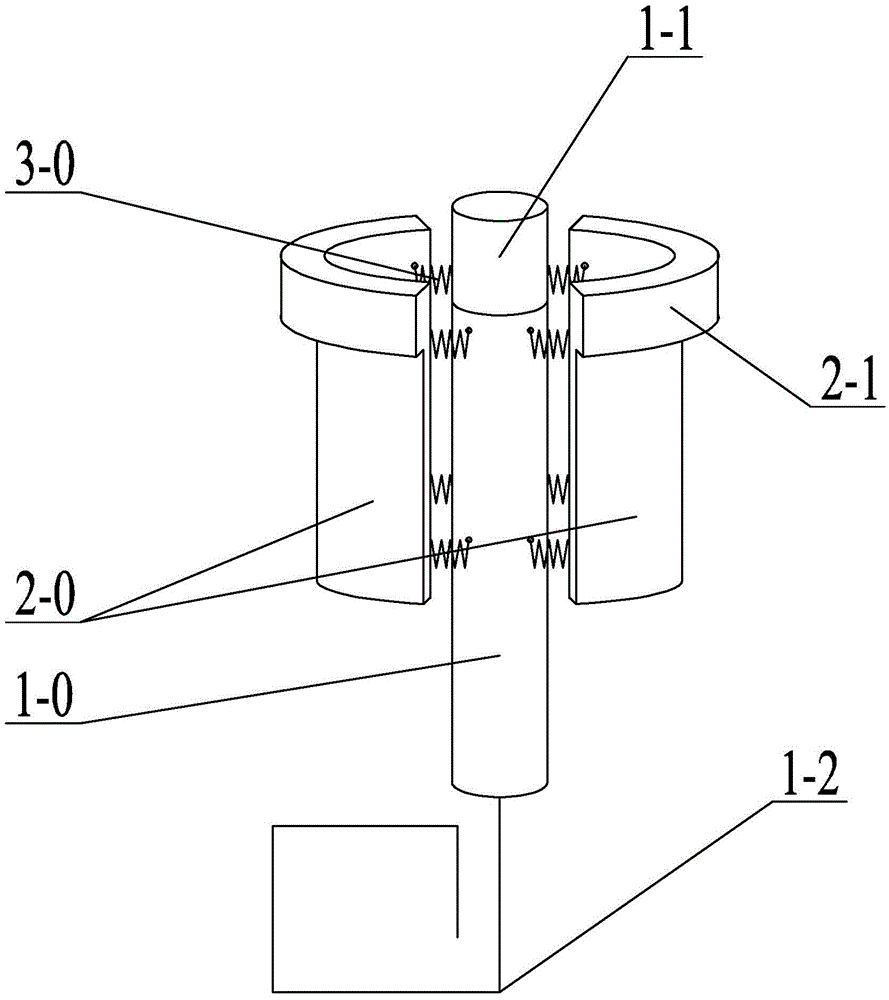

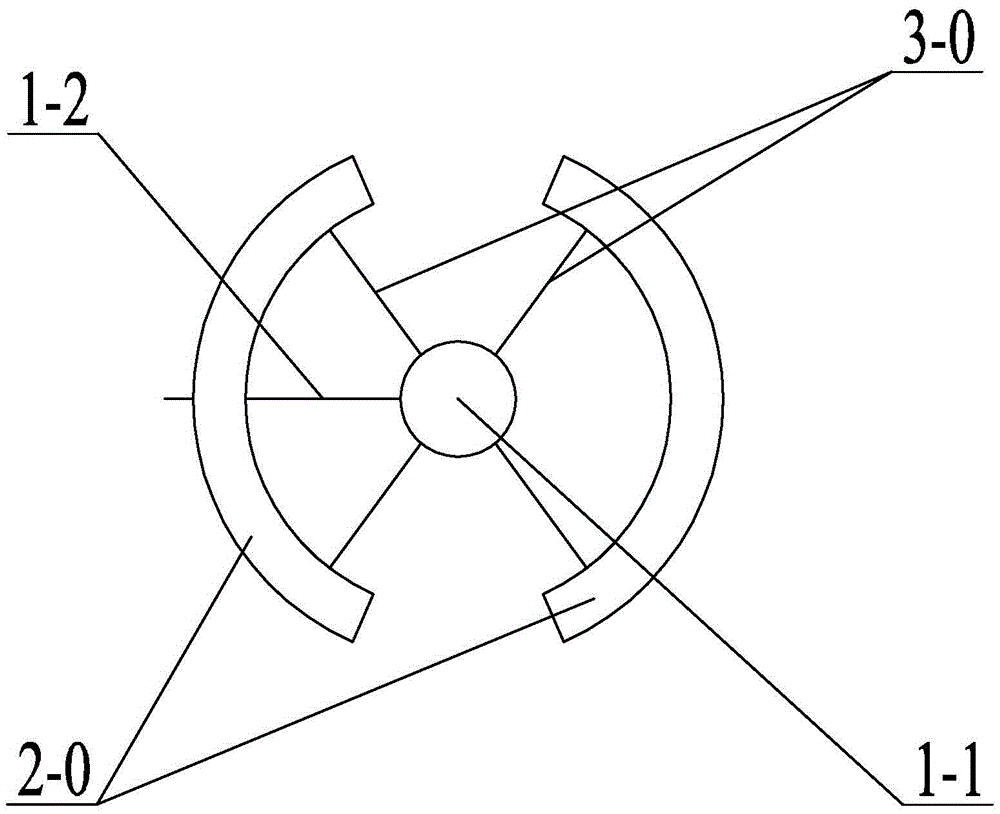

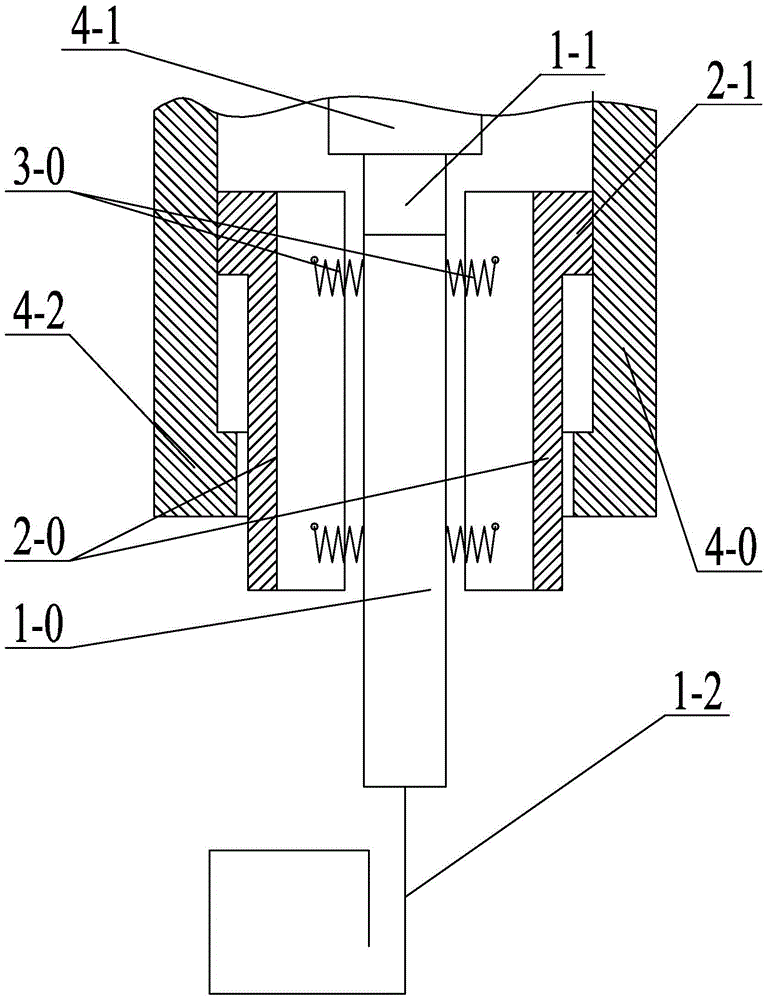

[0009] Specific implementation mode one: combine Figure 1 to Figure 3 Note that the fixing device in this embodiment includes a conductive rod 1-0, a magnet 1-1, a hook 1-2, two arc-shaped support pieces 2-0 and at least four springs 3-0,

[0010] The magnet 1-1 is fixed on one end of the conductive rod 1-0, the crotch 1-2 is fixed on the other end of the conductive rod 1-0, the concave arc surfaces of the two arc-shaped supporting pieces 2-0 are arranged oppositely, and the conductive rod 1-0 0 is vertically arranged between two arc-shaped support pieces 2-0, and the concave arc surface of each arc-shaped support piece 2-0 and the side wall of the conductive rod 1-0 are fixed by at least two springs 3-0 To connect, an arc-shaped boss 2-1 is affixed to the one end of the convex arc surface of the arc-shaped support piece 2-0 close to the conductive rod 1-0.

specific Embodiment approach 2

[0011] Specific implementation mode two: combination Figure 1 to Figure 3 Explain that the number of the springs 3-0 in this embodiment is eight, and four springs 3-0 form a group, and one end of each group of springs 3-0 is connected with the concave arc surface of an arc support piece 2-0 respectively. The four corners of the springs 3-0 are affixed to each other, and the other ends of the set of springs 3-0 are respectively affixed to the side walls of the conductive rod 1-0.

[0012] The eight springs 3-0 increase the supporting force of the two arc-shaped support pieces 2-0 on the inner wall of the secondary terminal port, making the fixing of the connection and fixing device of the present invention more reliable and meeting the needs of use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com