Ink-jet printing organic electroluminescence display and manufacture method thereof

An inkjet printing and display technology, which is applied in the fields of electrical solid devices, semiconductor/solid device manufacturing, circuits, etc., can solve the problems of difficulty in obtaining uniformity, small surface tension, and easy crystallization and separation, and shorten the fracture length of the liquid column Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

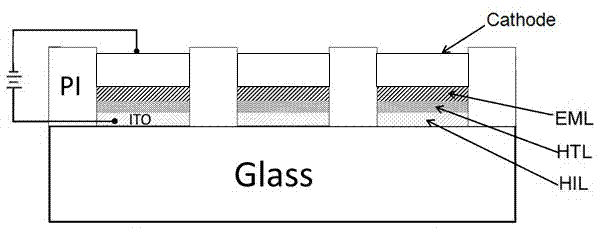

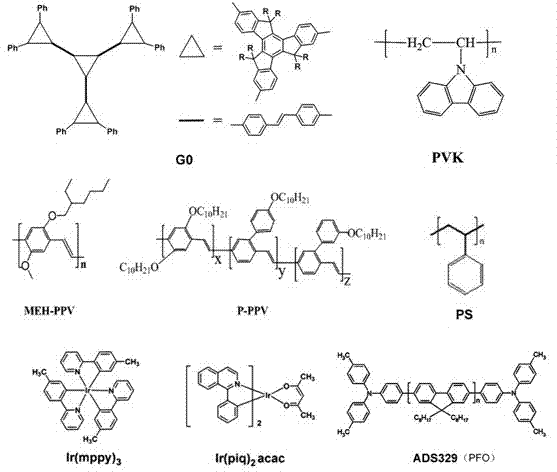

[0027] select figure 1 The inkjet printing display structure shown uses the patterned ITO transparent conductive glass as the substrate, cleans the surface pollutants with deionized water, blows them dry with high-pressure nitrogen, and uses ultraviolet light to irradiate them for surface modification, and then Prepare the PEDOT:PSS (polyaniline derivative) hole injection layer by spin coating on a 100-class ultra-clean bench, with a thickness of 40-80nm, heat at 200 degrees Celsius for 10 minutes in a nitrogen environment, and place it in a nitrogen glove box after cooling Spin coating PVK (polyvinyl carbazole, structure see figure 2 ) hole transport layer, the solvent is chlorobenzene, and the film thickness is about 40nm. Then spin-coat the blue light buffer layer (buffer layer), that is, the blue light-emitting layer film. The material of the buffer layer is dendritic compound G0 and blue light polyfluorene PFO (see the structure of figure 2 ) blended according to the ...

Embodiment 2

[0029] Repeat Example 1, the ratio used for inkjet printing red luminous solution is G0: Ir(piq) 2 acac:PS=100:10:1 (mass ratio), the ratio used for the green luminescent solution is G0: Ir(mppy) 3 :PS=100:10:1 (mass ratio), other conditions remain unchanged.

Embodiment 3

[0031] Repeat Example 1, the red luminescent solution used for inkjet printing is G0: MEH-PPV=10:1 (mass ratio), the green luminescent solution is G0: P-PPV=10:1 (mass ratio), and other conditions remain unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com