Fatigue test method and device for large parts of rail vehicle body structure

A technology for car body structure and fatigue testing, which is applied in railway vehicle testing, material analysis using radiation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

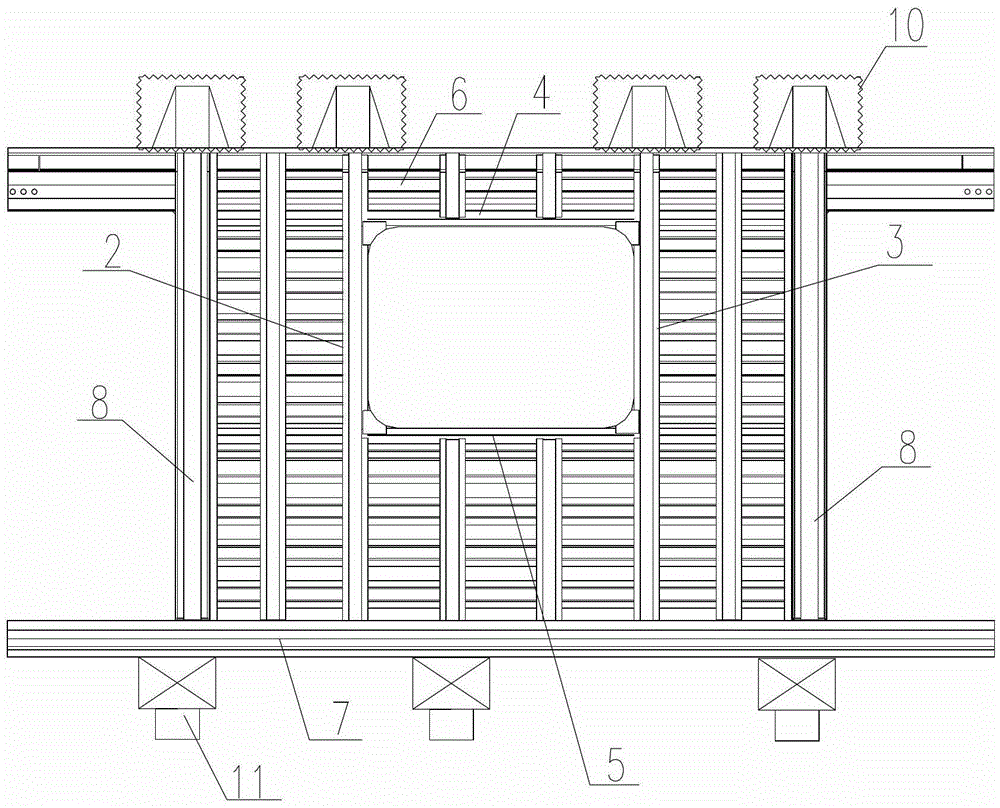

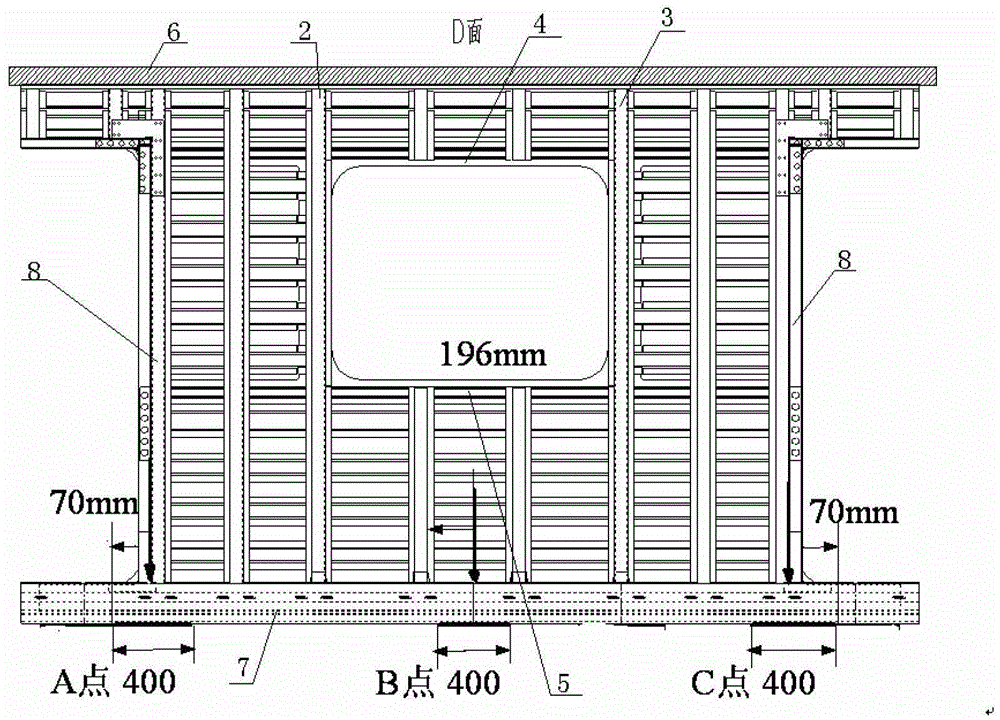

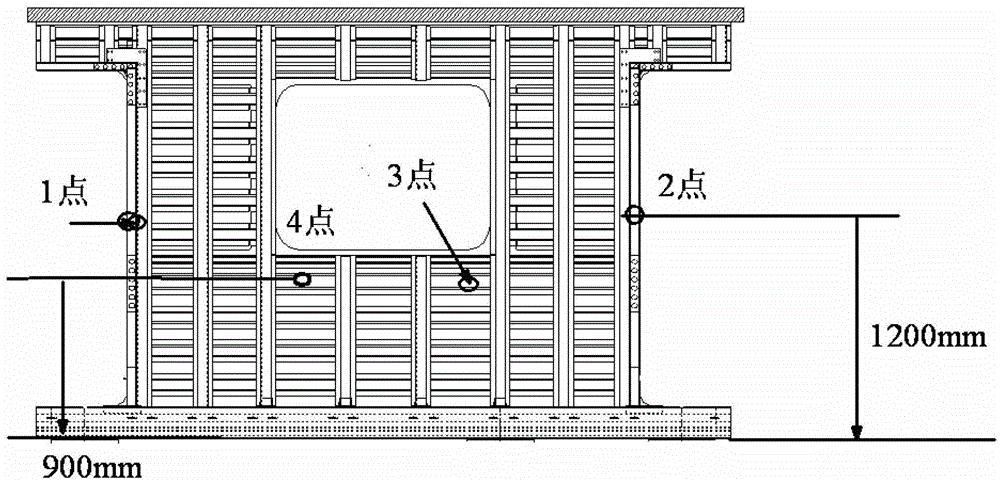

[0039] Such as figure 1 As shown, the fatigue test device for large parts of rail vehicle body structure according to the present invention takes the stainless steel laser welding subway car body structure as the test object to test the fatigue strength of the weld, such as large parts such as side walls and end walls of the subway. , which can be widely used in laser-welded car body tests operating in China.

[0040] In this embodiment, the side wall 1 is used as the vehicle body structure to be tested for testing. The side wall 1 is welded by the left window column 2, the right window column 3, the upper beam of the window 4, the lower beam of the window 5, the side beam of the side wall 6, the lower beam of the side wall 7, the door column 8 and the side wall panel 9. 1 is a stainless steel material, and each weld seam is welded by laser we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com