A gas cooker burner with stable inner ring flame

A gas cooker and flame stabilization technology, which is applied to gas fuel burners, burners, combustion methods, etc., can solve the problems of thermocouple automatic flameout, failure, difficulty in gas ignition, etc., and achieves the effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

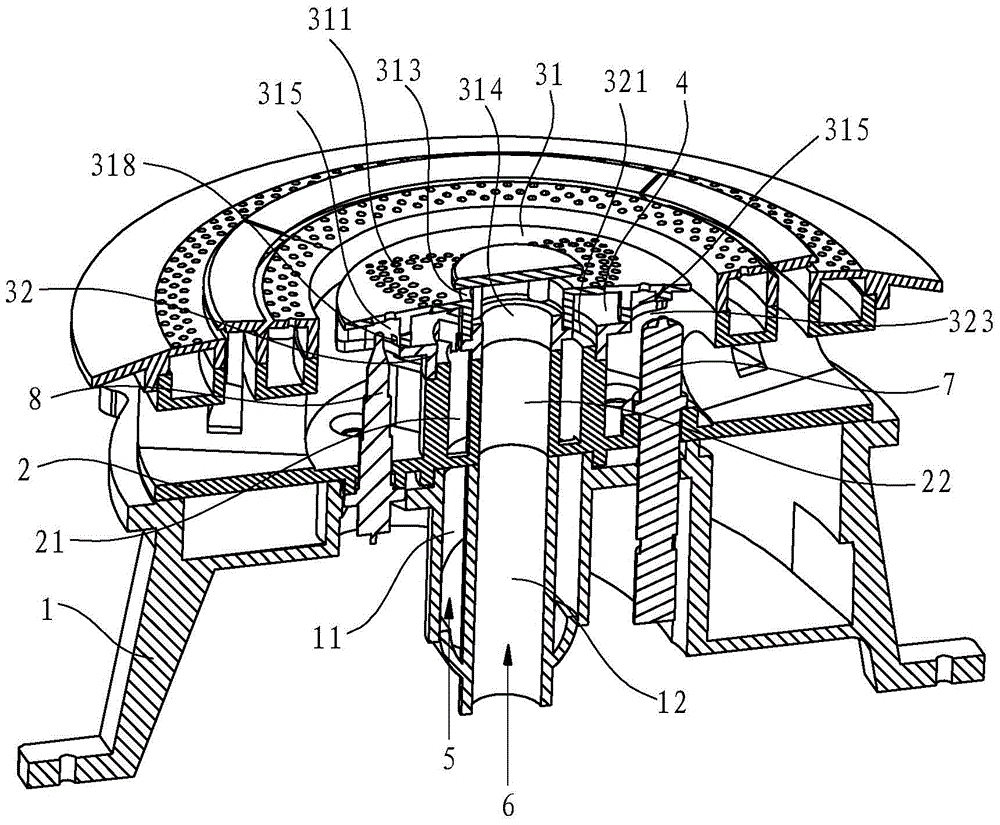

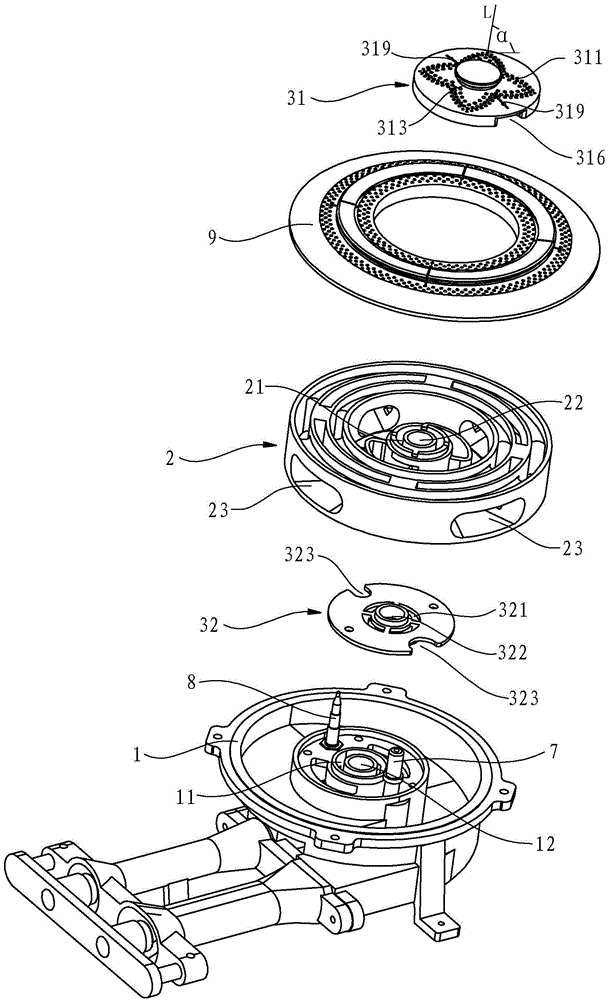

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

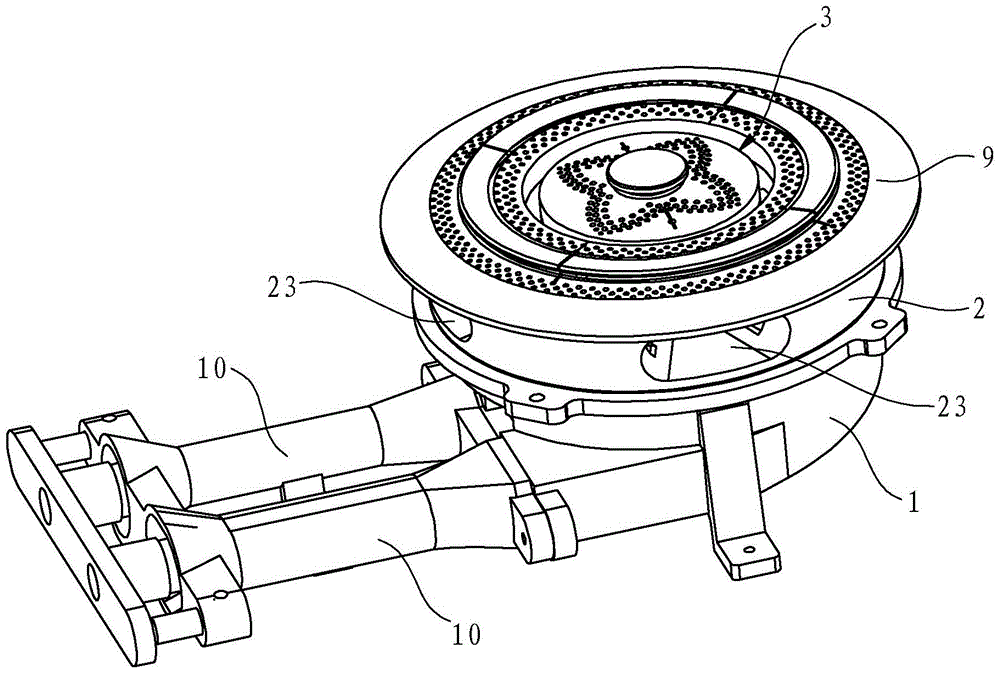

[0023] like Figure 1 to Figure 5 As shown, the gas cooker burner in this embodiment includes a base 1, an air mixing chamber 2 and an inner ring fire cover 3, wherein the base 1 is installed on the injection pipe 10, and the air mixing chamber 2 is installed on the base 1 On, the inner ring fire cover 3 and the outer ring fire cover 9 are installed on the mixing chamber 2. The base 1 and the gas mixing chamber 2 have an inner ring gas channel 5 that penetrates up and down. The inner ring fire cover 3 forms an annular cavity 4 that communicates with the inner ring gas channel 5. The central part of the bottom of the annular cavity 4 is connected to the inner ring gas channel. Channel 5 is connected.

[0024] Inner ring fire cover 3 comprises fire cover body 31 and is located at the fire cover body lower sealing plate 32 below the fire cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com