X-type open full-face tunnel boring machine

A tunnel boring machine, full-section technology, used in tunnels, mining equipment, earth-moving drilling and other directions, can solve the problems of a small number of support shoe plates, a limited support area, and the tunneling machine sinking, etc., to achieve high flexibility and support area. Large and adaptable to the effect of a wide range of surrounding rocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

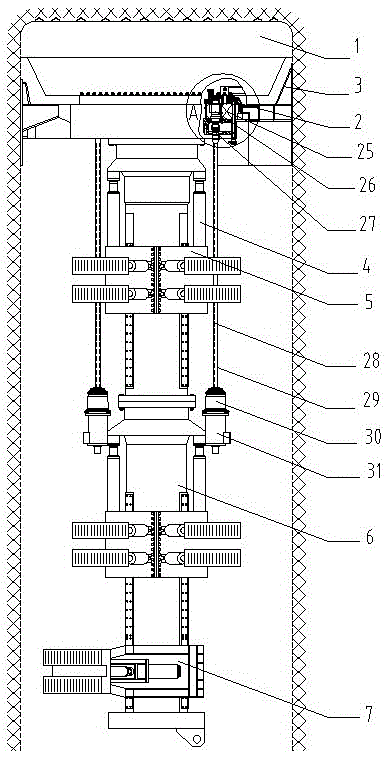

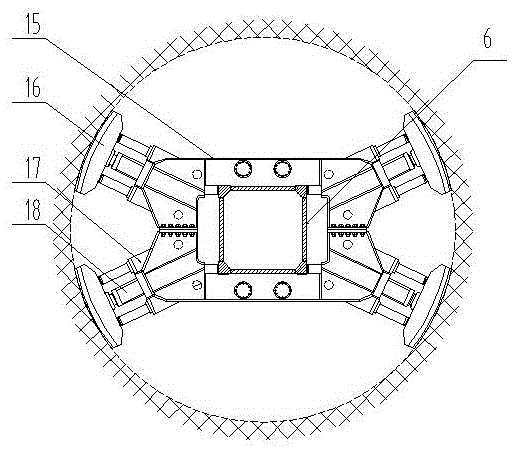

[0022] Such as Figures 1 to 5 As shown, the X-type open full-face tunnel boring machine of the present invention includes a drive system 2 and a cutter head 1 installed at the front end of the drive system. connection, the outer casing assembly 5 is installed on the inner casing assembly 6 through the propulsion system 4, and the center lines of the cutter head 1, the drive system 2, the shield system 3, the inner casing assembly 6 and the rear support assembly 7 are on the same axis , The cutter head 1, the drive system 2, the shield system 3, and the Nekai assembly 6 are connected by bolts in turn. The outer casing assembly 5 is installed on the slide rail of the inner casing assembly 6 , and under the action of the propulsion system 4 , it has a certain sliding capacity along the inner casing assembly 6 . One end of the propulsion system 4 is bolted to the inner casing assembly 6, and the other end is bolted to the outer casing assembly 5. The tail end of the inner casin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com