Method for Measuring the Shock Vibration State of Downhole Instruments While Drilling

A downhole instrument and shock vibration technology, which is applied in the field of oil drilling, can solve the problems of deformation of the joints of downhole sub joints, reduce operation safety, inconvenient use, etc., to prevent accidents, have high operation safety, and ensure continuity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

[0029] In this specification, the term "upper, upper end, above" refers to the side away from the center of the earth along the longitudinal direction of the drill string; the term "lower part, lower end, below" refers to the side toward the center of the earth along the longitudinal direction of the drill string.

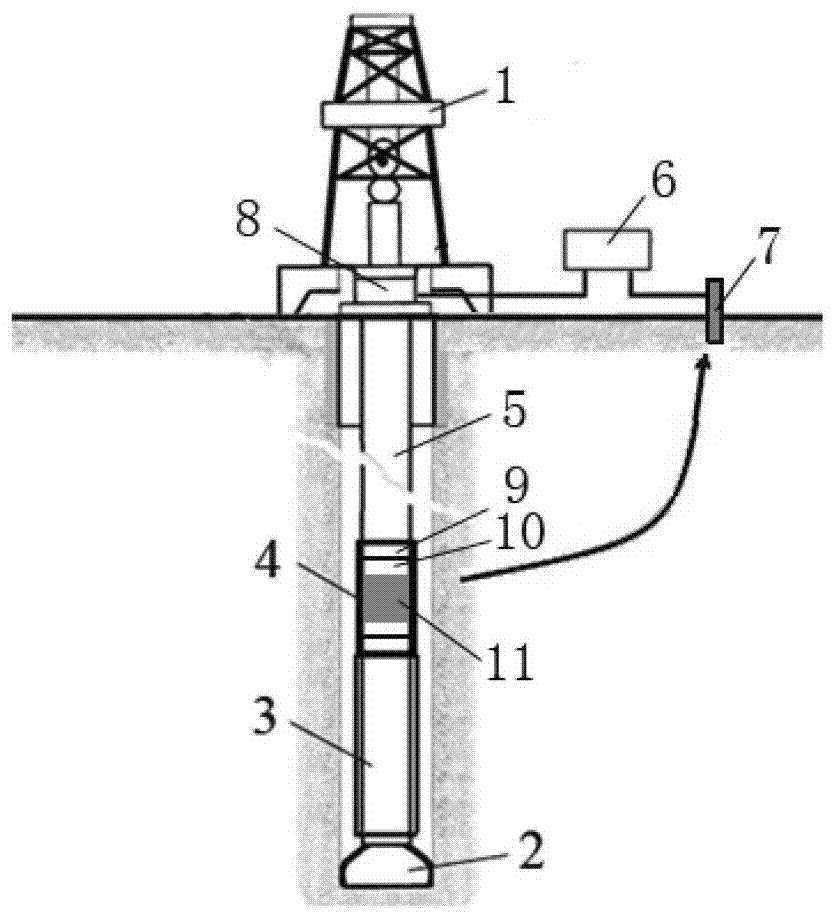

[0030] figure 1 Shows the conventional drilling equipment installed with the system for measuring the shock vibration state of downhole instruments while drilling according to the present invention, including a derrick 1, a drill bit 2, an instrument to be tested 3, a drill string 5, etc., since the above structure is a common drilling The structure in the device is easily understood by those skilled in the art, and the markings in the drawings are only for the convenience of understanding the present invention, and will not be introduced in detail i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com