Anti-floating and waterstop construction method for small-area deep foundation pit of building

A construction method and small-area technology, which is applied in construction, infrastructure engineering, excavation, etc., can solve the problems of long construction period, limited range of precipitation influence, and influence on precipitation effect, and achieve good precipitation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the examples, and the purpose is only to better understand the content of the present invention.

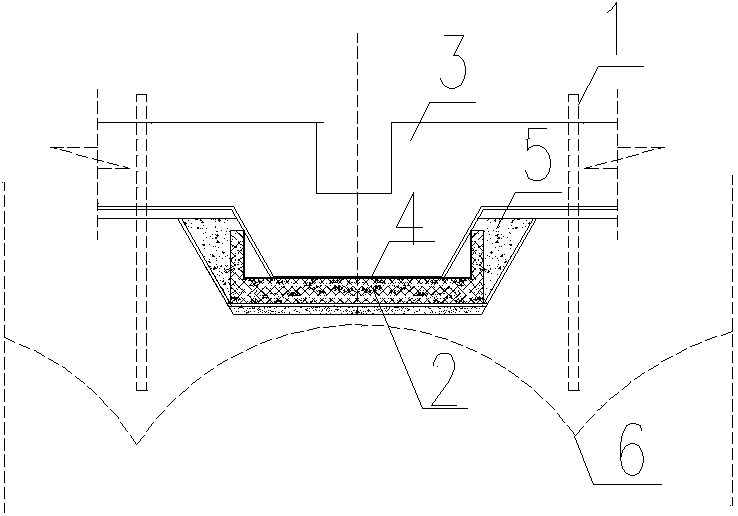

[0021] see figure 1 , figure 2 , the anti-floating and water-stop construction method of the small-area deep foundation pit of the building described in the present embodiment is carried out according to the following steps:

[0022] 1. Carry out well point dewatering around the small-area deep foundation pit, drill the dewatering well 1, pump water with a vacuum pump or submersible pump, and lower the groundwater level 6 to 500mm below the raft 3.

[0023] 2. Excavate a small area of deep foundation pit earthwork.

[0024] 3. The buoyancy is calculated according to the volume of water displaced by the raft 3, the concrete anti-floating protective shell 2 is designed, and then the concrete anti-floating protective shell 2 is constructed.

[0025] 4. The waterproof membrane 4 is laid inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com