Hollow anchor rod

A bolt and hollow technology, which is applied in the installation of bolts, sheet pile walls, mining equipment, etc., can solve problems such as weak anchoring force, small gripping force, and small ultimate tensile force, so as to improve the bearing capacity of the bolt and simplify construction steps, the effect of less prestress loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

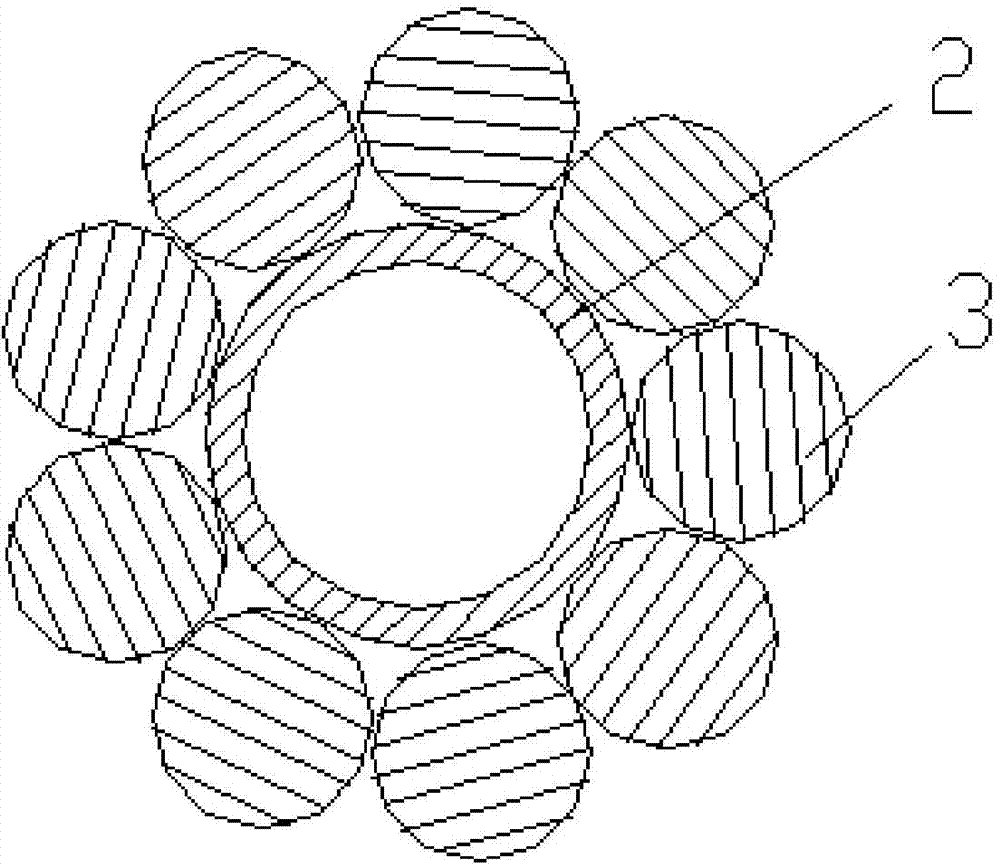

[0023] Such as Figure 1 to Figure 4 As shown, the present invention includes a rod body 1, and the rod body 1 includes a central casing 2 and nine spiral rib steel wires 3 on the periphery, and the steel wires 3 are helically wound on the periphery of the casing 2 at an angle of 7-8°. The casing 2 is provided with a grouting hole 4 . One end of the casing 2 has an annular groove 7 for fixing the slurry stopper placed in the casing 2 . During grouting, grouting can be performed from an opening at one end of the casing 2, and then overflow from the grouting hole 4, and the grout stopper can effectively prevent the grout from backflowing.

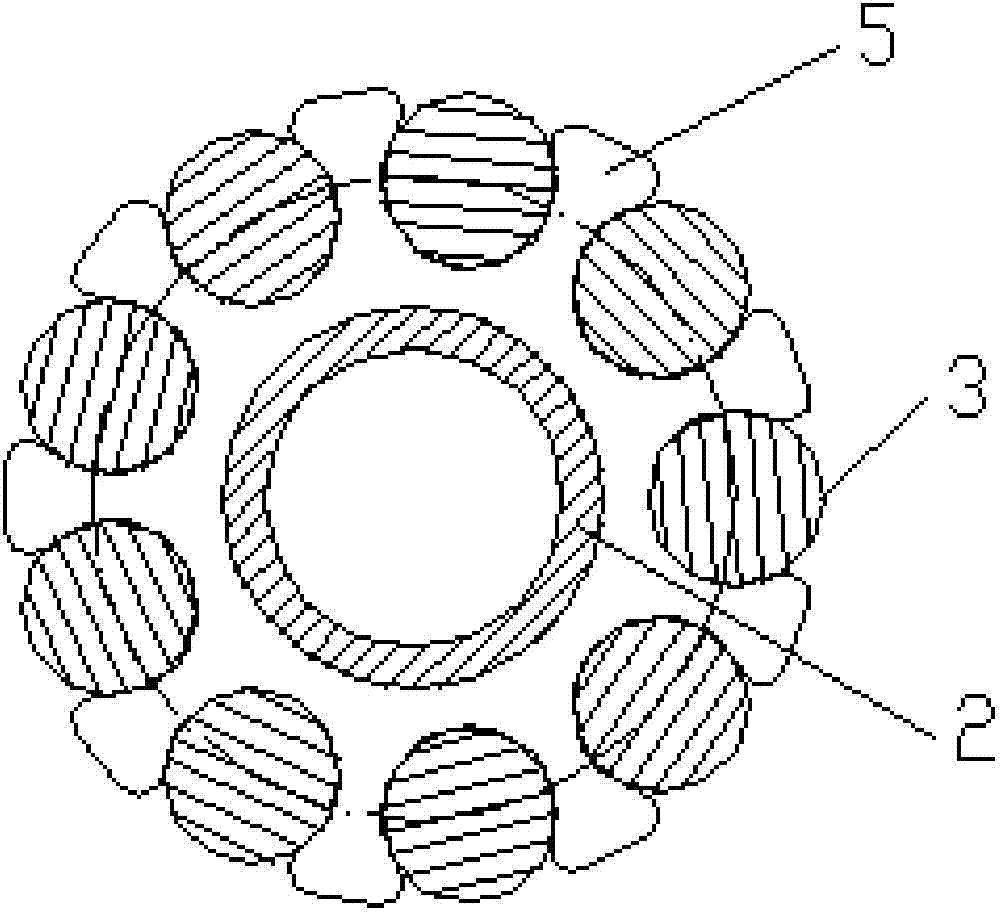

[0024] The rod body 1 also includes a number of annular locators 5 that are sleeved on the outside of the sleeve 2. The annular locators 5 are a spline structure, and the cross section of the keyway is an ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com