A material distribution mechanism of an injection molding product feeder

A technology of injection molding products and material distribution mechanism, which is applied in the direction of conveyors, transportation and packaging, etc., can solve the problems of no solution, inability to use valve blanking and material distribution mechanism, and inability to copy and copy sleeves, etc., to achieve the goal of improving material distribution efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with drawings and embodiments.

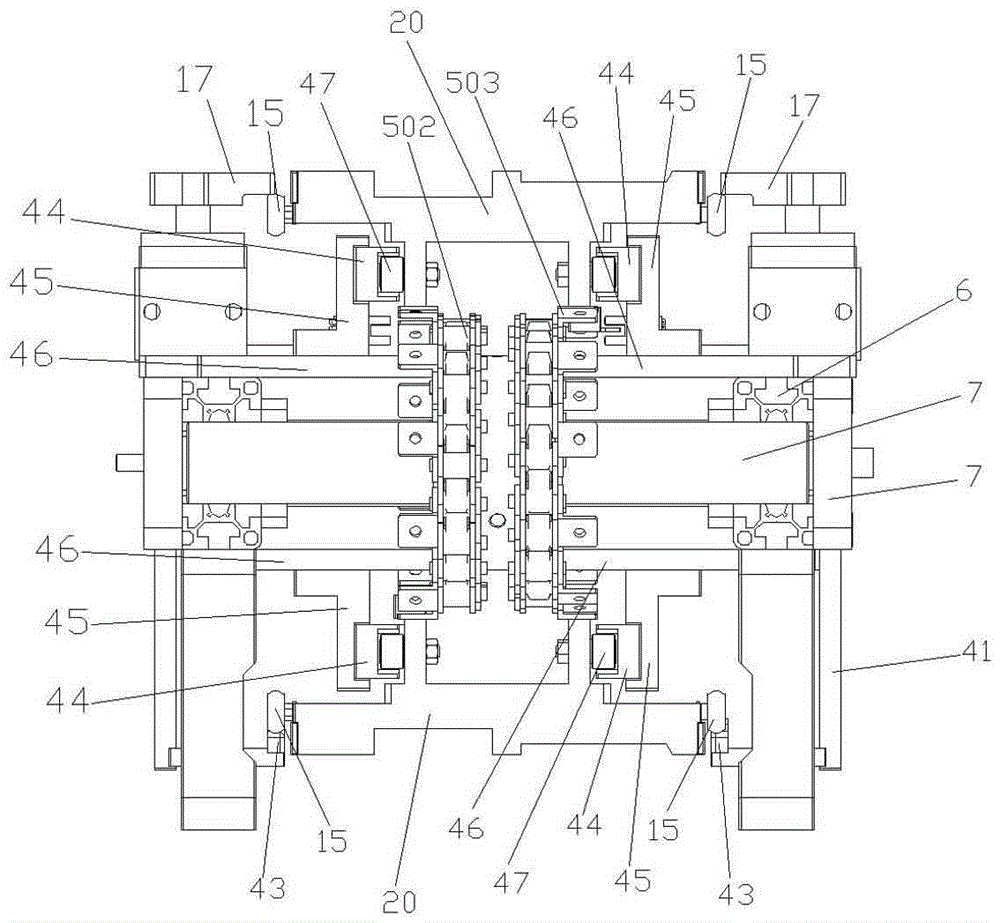

[0031] like Figure 4 As shown, the cross-section of the support rod 6 is a square, and there are installation grooves on the four sides. Two vertical and two horizontal support columns 7 form a frame-shaped structure. There are four fixed plates 8 with shaft holes 801 on them, which are fixedly installed on the two ends of the support rod 6 respectively; On the surface, there are four supporting feet 9.

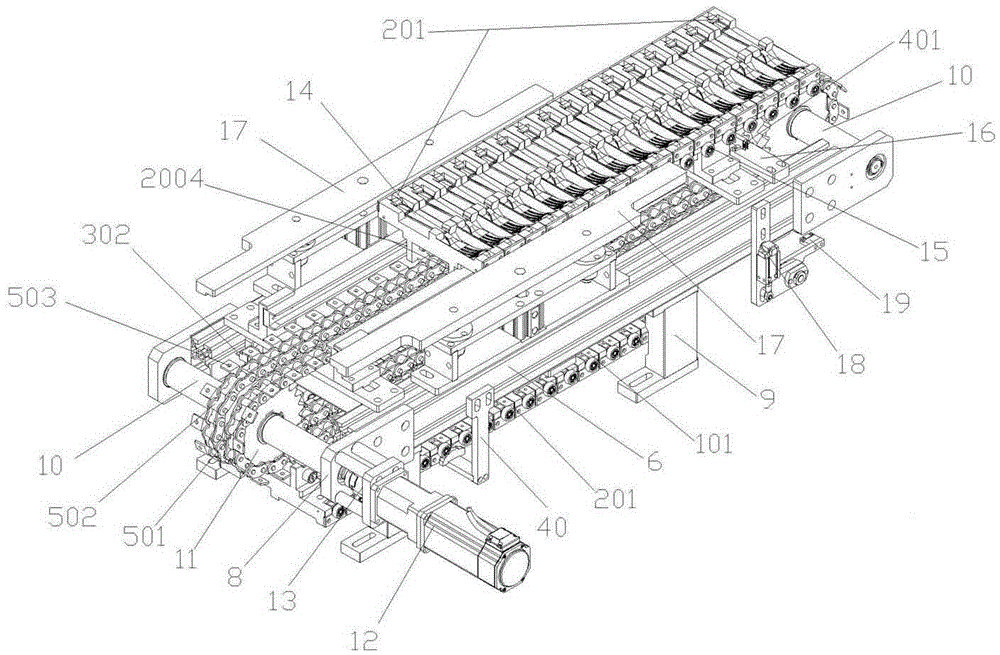

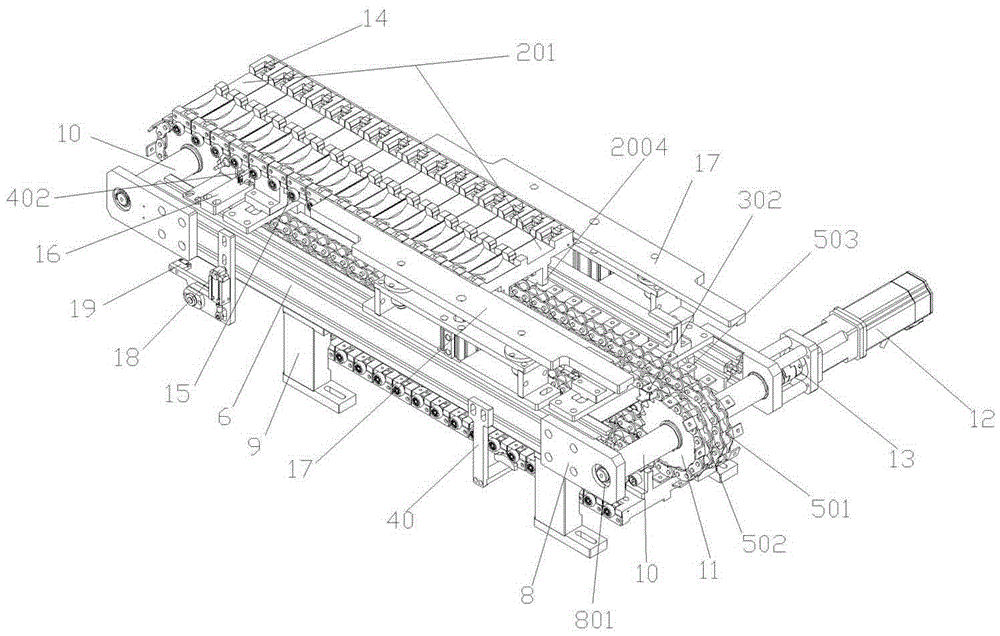

[0032] like figure 1 , 2 , 5, there are two rotating shafts 10, which are respectively installed in the shaft hole 801 of the fixed plate 8 at the two ends of the support rod 6, and the sprocket wheel 11 is a single double row sprocket wheel, and there are two, which are respectively installed on the rotating shaft 10, There are two chains, arranged in parallel on the left and right, the first chain 501 on the right, and the second chain 502 on the left. Both chai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com