A kind of preparation method of feed

A feed and material technology, applied in animal feed, animal feed, applications, etc., can solve the problems of unreasonable utilization of feathers and animal hair, low production efficiency, high cost, etc., to promote decomposition and conversion rate, increase content, and improve palatability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

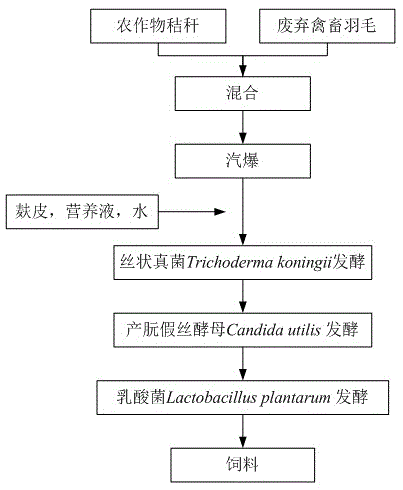

Method used

Image

Examples

Embodiment 1

[0045] Crush the crop corn stalks, the length is 5cm, mix the crushed corn stalks with chicken feathers, according to the mass ratio of corn stalks and chicken feathers is 10:1, the mixture is sent into the steam explosion tank for steam explosion treatment, at a pressure of 0.8MPa Maintain the temperature for 20 minutes, and obtain steam explosion materials after treatment. After the steam explosion material and the bran are mixed in a mass ratio of 7:1, add (NH 4 ) 2 SO 4 5%, glucose 2%, H 3 PO 4 1%. , adjust the water content of the mixture to 40%, and the pH is 4.0, inoculate 30% of the filamentous fungus Trichodermakoningiiz at 28°C for 7 days, then inoculate 30% of Candidautilis at 28°C for 5 days, and finally inoculate 30% The lactic acid bacteria Lactobacillus plantarum were cultured at 28° C. for 5 days.

[0046] After the fermentation, the mixture is dried at 60°C until the water content is less than 12% to obtain the feed product. Use the Kjeldahl method to m...

Embodiment 2

[0048] Crush the wheat straw of the crops, the length is 5cm, mix the crushed wheat straw with chicken feathers, according to the mass ratio of wheat straw to chicken feathers is 5:1, send the mixture into the steam explosion tank for steam explosion treatment, at a pressure of 1.5MPa Maintain the temperature for 10 minutes, and obtain the steam explosion material after treatment. After the steam explosion material and the bran are mixed in a mass ratio of 7:1, add (NH 4 ) 2 SO 4 5%, glucose 2%, H 3 PO 4 1%. , adjust the water content of the mixture to 40%, and the pH is 4.0, inoculate 30% of the filamentous fungus Trichodermakoningiiz at 28°C for 7 days, then inoculate 30% of Candidautilis at 28°C for 5 days, and finally inoculate 30% The lactic acid bacteria Lactobacillus plantarum were cultured at 28° C. for 5 days.

[0049] After the fermentation, the mixture is dried at 60°C until the water content is less than 12% to obtain the feed product. Use the Kjeldahl metho...

Embodiment 3

[0051] Crush the crop rice stalks with a length of 5cm, mix the crushed rice stalks with chicken feathers, and send the mixture into a steam explosion tank for steam explosion treatment according to the mass ratio of rice stalks and chicken feathers at a pressure of 2MPa. Maintain it for 8 minutes, and obtain steam explosion material after treatment. After mixing the steam explosion material and the bran in a mass ratio of 8:1, add (NH 4 ) 2 SO 4 3%, Glucose 1%, H 3 PO 4 1%. , adjust the water content of the mixture to 50%, PH is 4.5, inoculate 20% filamentous fungus Trichodermakoningiiz at 28°C for 7 days, then inoculate 20% Candidautilis at 28°C for 5 days, and finally inoculate 30% The lactic acid bacteria Lactobacillus plantarum were cultured at 28° C. for 5 days.

[0052] After the fermentation, the mixture is dried at 60°C until the water content is less than 12% to obtain the feed product. Use the Kjeldahl method to measure the crude protein content in the feed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com