Suspension type movable branch cutting device

A hanging and pruning technology, applied in cutting tools, cutting equipment, gardening, etc., can solve the problems of waste of manpower and material resources, slow speed, and branches affecting the safety of wires, etc., to achieve high work efficiency and ensure safe power supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

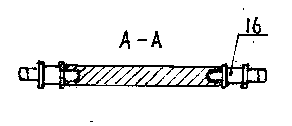

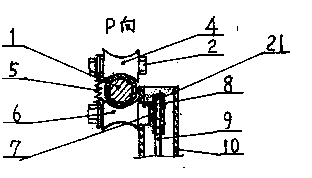

[0011] Examples, see attached Figure 1~3 , the suspended movable pruning device is a trapezoidal outer shield 15, and a motor 13 is installed at the bottom. Drive sprocket 11 is housed on the shaft that goes out of machine 12. The top of the outer shield 15 is provided with a square hole 15-1, and two parallel insulating supports 10 are fixed above the square hole 15-1 of the outer shield 15, and a bearing seat 21 is arranged on the upper inner side wall of the support 10. The built-in driven sprocket shaft 7 of the bearing in the bearing seat 21, the driven sprocket 8 is installed on the driven sprocket shaft 7 in the support 10, and the driven sprocket 8 is connected with the drive sprocket 11 transmission with the chain 9. On the driven sprocket shaft 7 outside the bracket 10, a lower roller 6 with a concave arc shape is installed, and two return springs 5 are fixedly installed on the driven wheel shaft 7 outside the lower roller 6, and the other ends of the two return ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com