Connector

A technology of connectors and housings, which is applied in the direction of connections, components of connection devices, electrical components, etc., and can solve problems such as the inability to omit the anti-off structure, the large gap, and the increase in the width of the locking arm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

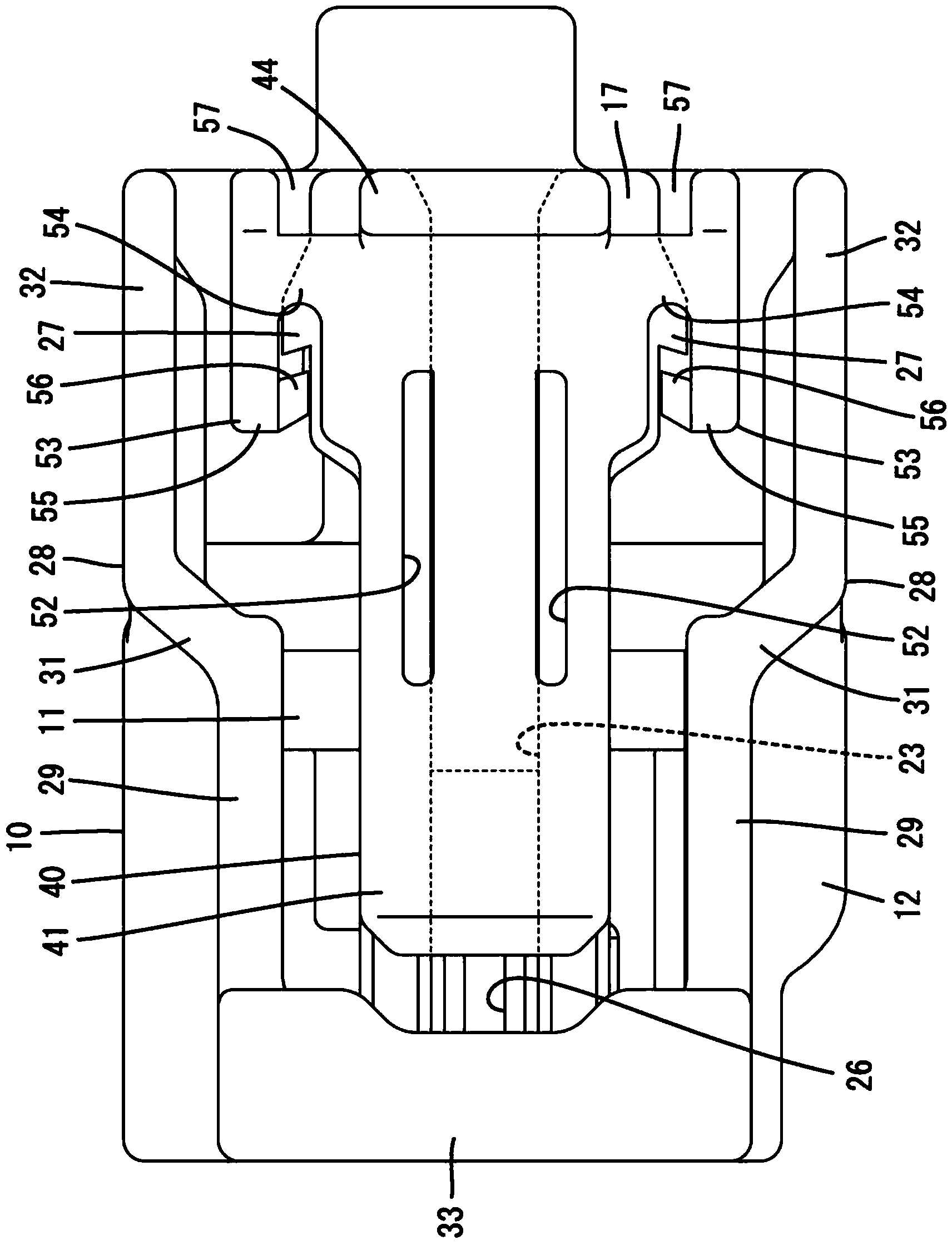

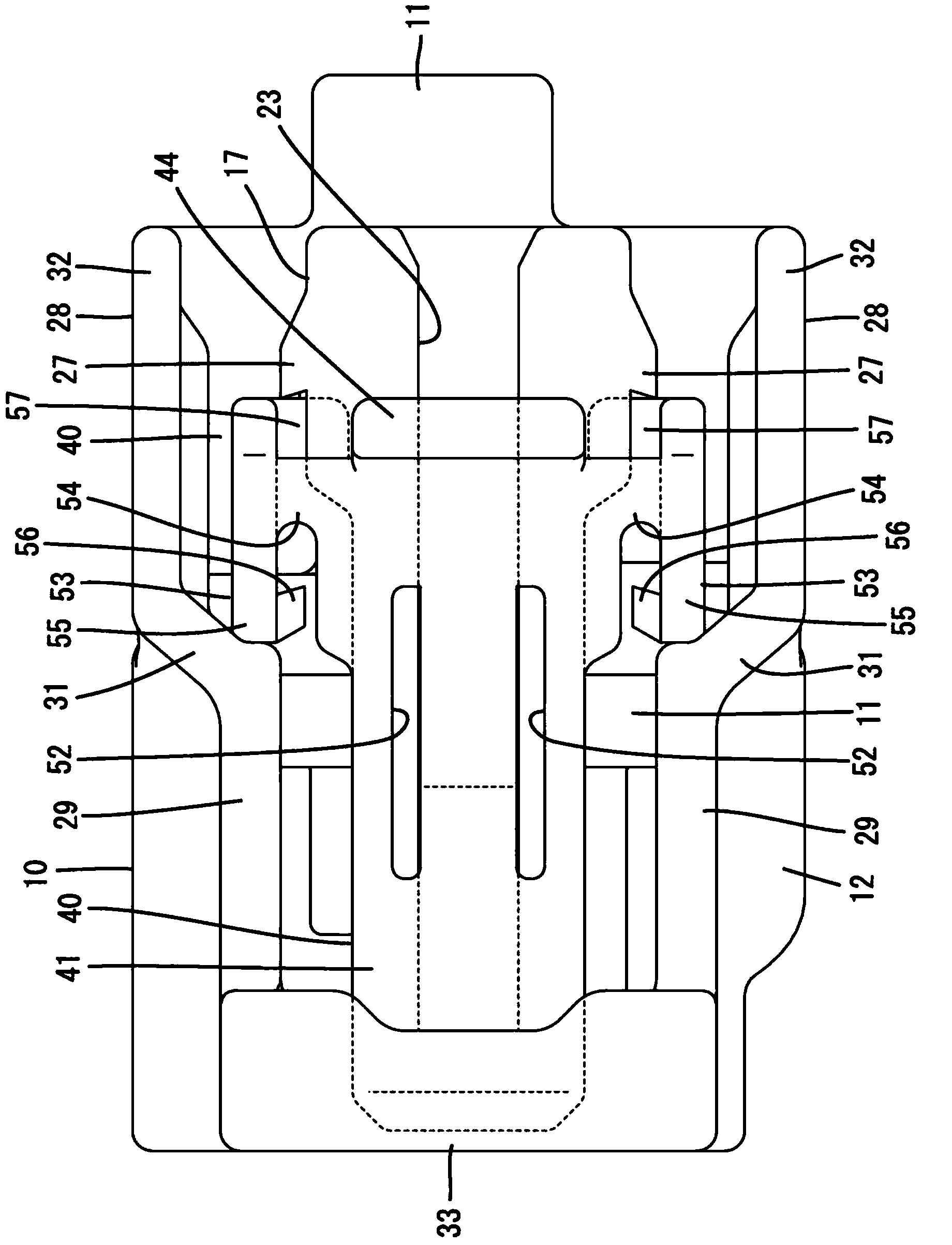

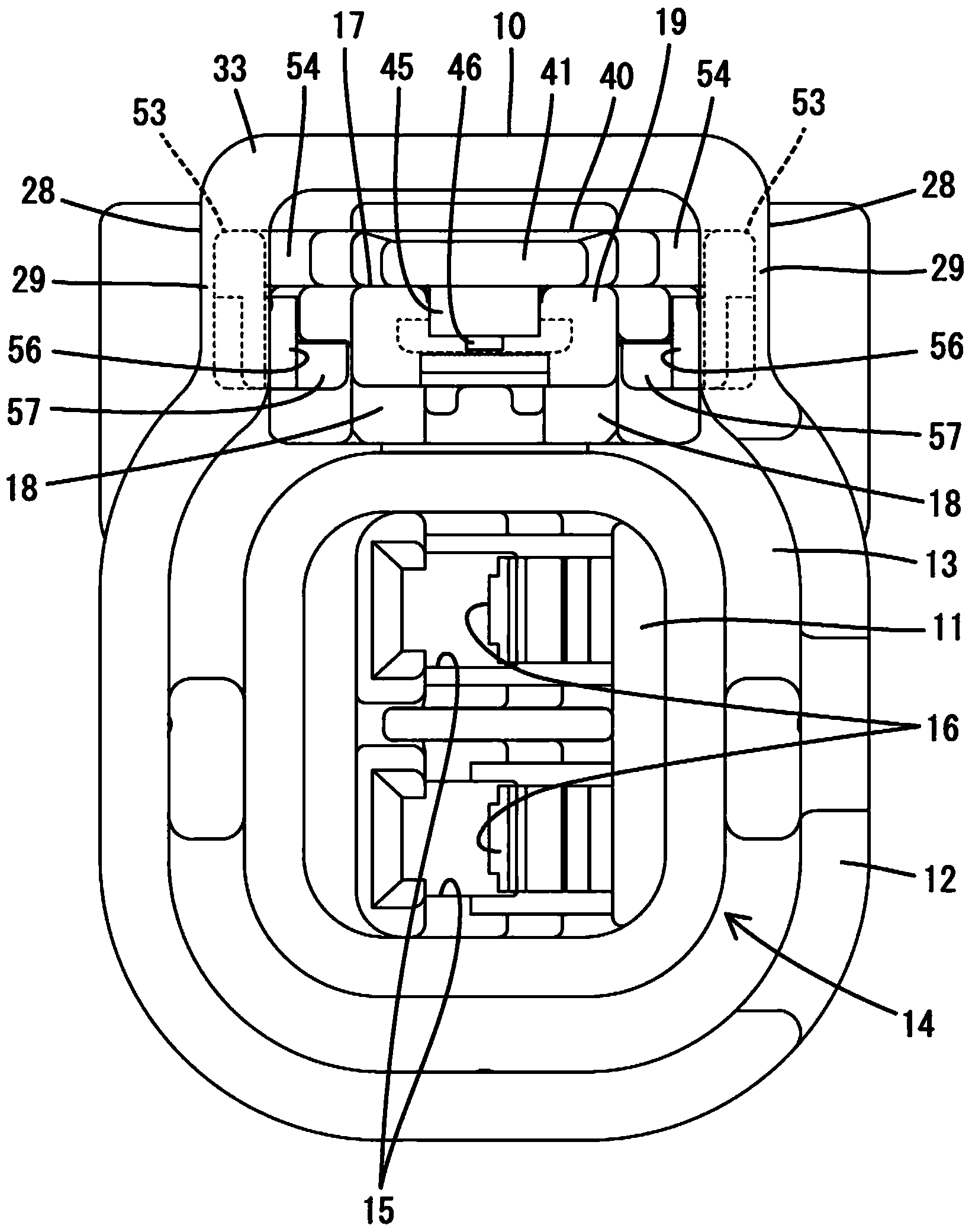

[0032] use Figure 1 to Figure 13 Example 1 of the present invention will be described. The connector of the present embodiment is capable of fitting with a mating housing 100 , and is configured to include a housing 10 , a slider 40 , and a terminal fitting 70 . In addition, in the following description, regarding the front-rear direction, the side of the mating surface with respect to the counterpart housing 100 is defined as the front.

[0033] Such as Figure 5 As shown, the counterpart housing 100 is made of synthetic resin and has a cylindrical cover portion 101 . A locking portion 102 protrudes from the upper surface of the upper wall of the cover portion 101 , and a pair of guide ribs (not shown) protrude from both sides in the width direction of the locking portion 102 . The two guide ribs are formed to extend substantially parallel to each other in the front-rear direction. Furthermore, the male protruding piece 201 of the mating terminal fitting 200 is protrudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com