Variable groove width skeleton tool and method for forming fiber rings by utilizing tool

A molding method and slot width technology, which can be used in measuring devices, instruments, etc., can solve the problems that affect the temperature performance of the formed optical fiber ring, it is difficult to meet the temperature and mechanical properties at the same time, and the internal structure of the photonic crystal fiber, etc., and achieve the minimum deformation. , The effect of reducing stress concentration and reducing the influence of structural deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The invention combines the particularity of the internal structure of the photonic crystal fiber, and adopts special fiber wrapping technology, curing technology and aging treatment measures to realize the forming of the photonic crystal fiber ring. The specific implementation method is as follows:

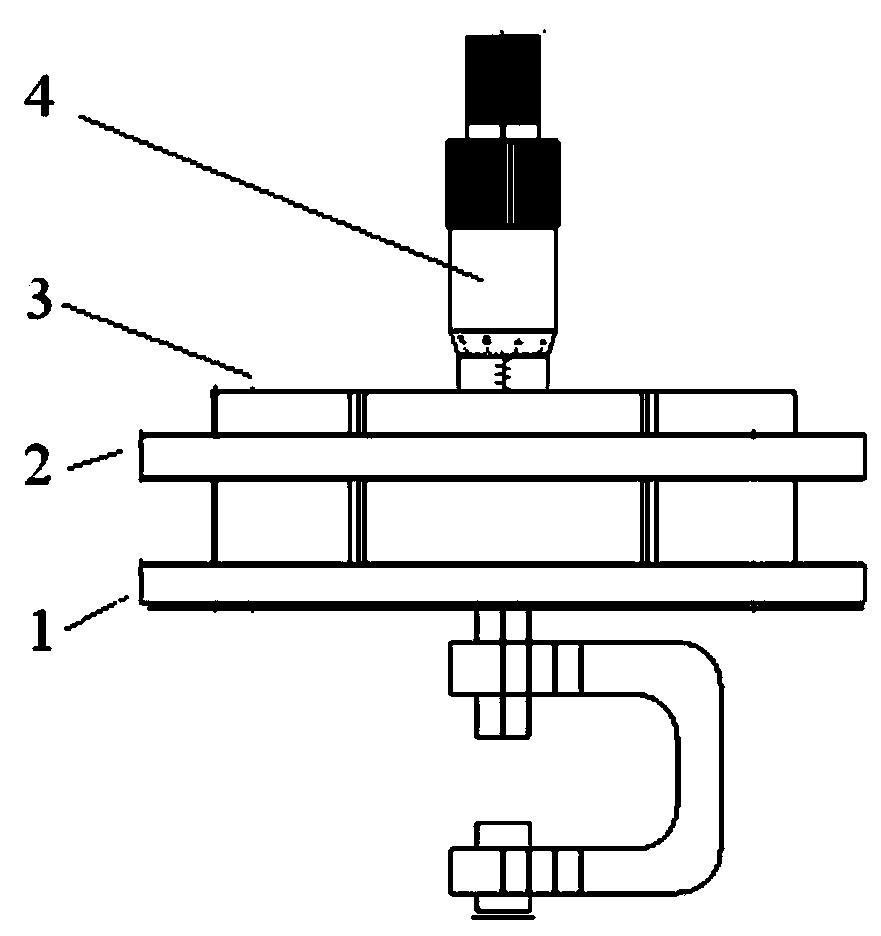

[0033] (1) Integer turn winding control technology

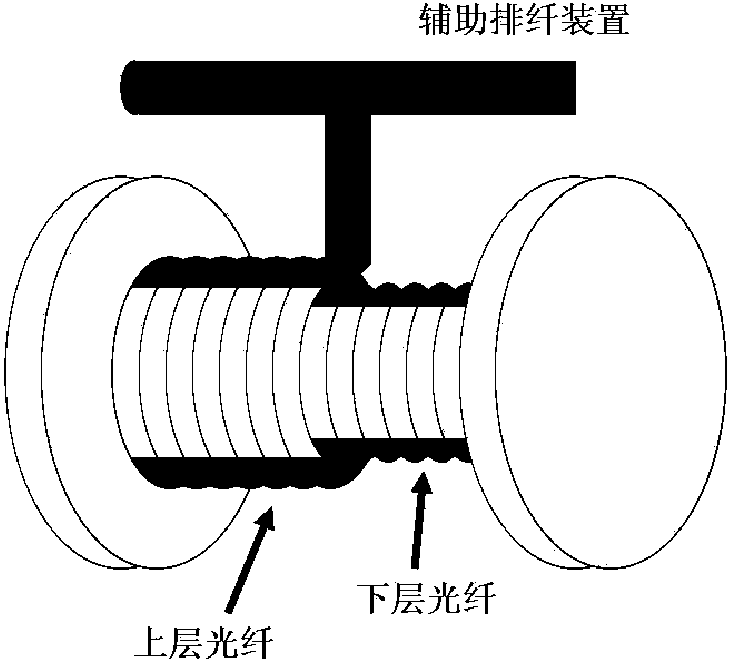

[0034] Such as Figure 1a , Figure 1b As shown, a skeleton tooling with a variable groove width of the present invention mainly includes a cover A1, a cover B2, a hub 3, a displacement control screw 4, and a crossbeam 5; the cover A1 and the cover B2 are circular structures; the hub 3 It is composed of two semi-annular hollow cylindrical shells spliced together, and there is a gap between the two semi-annular hollow cylindrical shells; the cover A1 is fixedly connected to the axial end surface of the hub 3 side; the cover B2 is sleeved on the hub 3 On the outer diameter of the cover sheet B2, a crossbeam 5 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com