Embedded laser displacement sensor and normalization processing method thereof

A technology of laser displacement and sensors, which is applied in the field of sensors in the field of displacement measurement technology, can solve the problems of different quality of received signal waveforms, measurement errors, drops, etc., and achieve the effect of ensuring normalization and overcoming measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

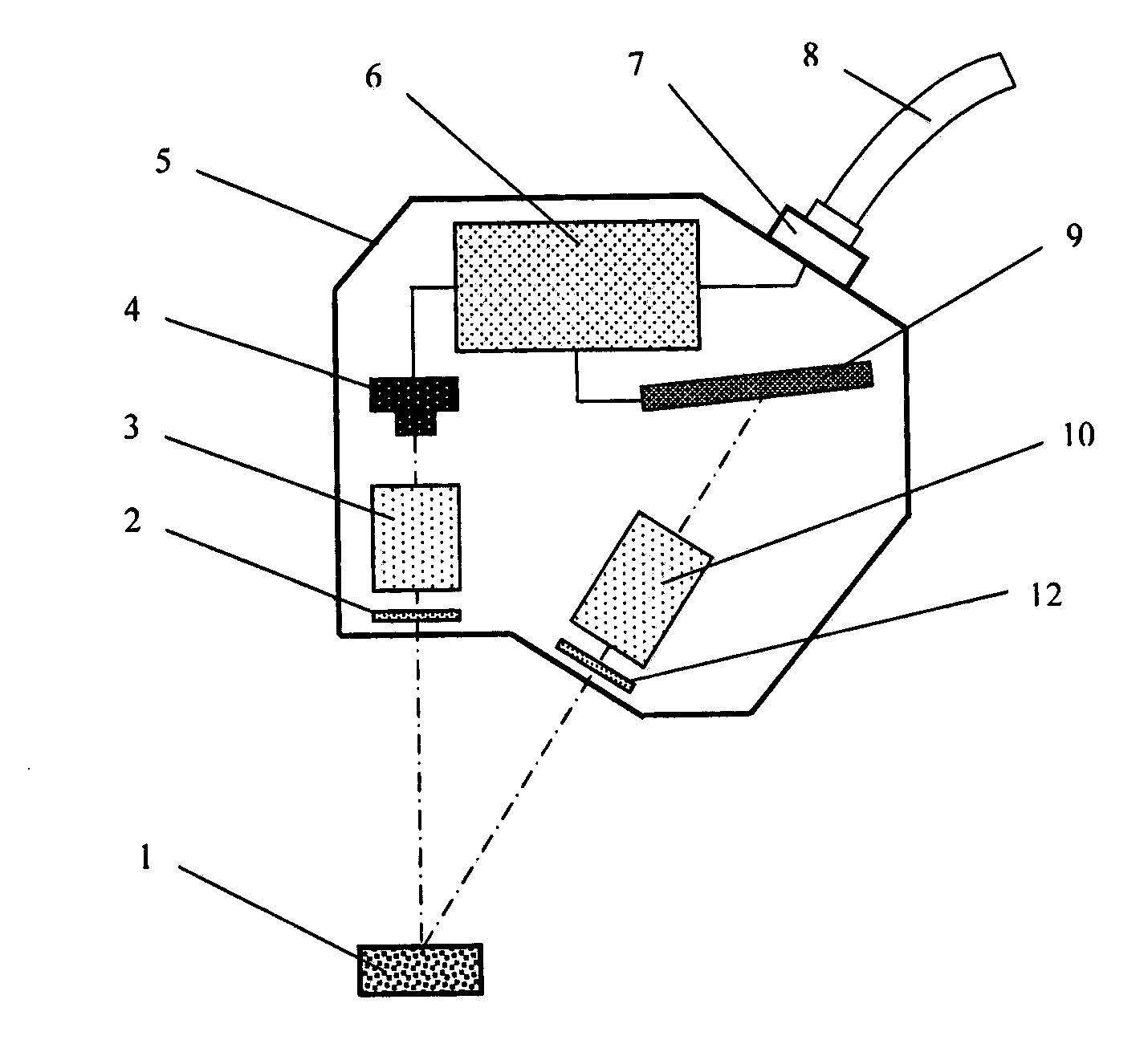

[0030] Such as figure 1 As shown, the laser displacement sensor of the present invention mainly includes: emission filter 2, emission mirror group 3, laser device 4, housing 5, processing circuit 6, socket 7, cable 8, photoelectric device 9, receiving mirror group 10, receiving filter Light sheet 11. The working process of the whole system is: after the laser beam emitted by the laser 4 is collimated and focused by the transmitting mirror group 3, it is irradiated on the surface of the measured target 1 and forms a spot, which is imaged on the photoelectric device 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com