Machine tool adjustment cushion

A technology for adjusting pads and machine tools, applied in the direction of supporting machines, mechanical equipment, engine frames, etc., can solve problems such as deformation, insufficient simplicity, and difficulty in guaranteeing, and achieve the effects of preventing sliding, strong grip, and precise structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

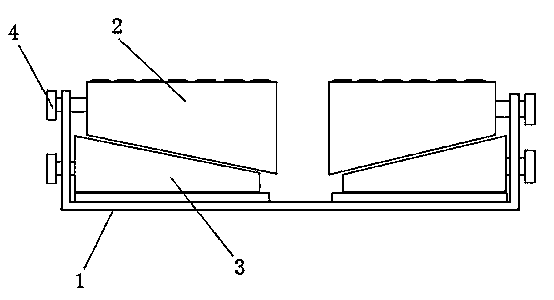

[0016] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] Such as figure 1 As shown, a machine tool adjustment pad of the present invention includes a groove base 1, and two sets of sliding gaskets are arranged in the groove base 1, and each group of sliding gaskets includes an upper pad 2 and a lower pad Block 3, the mutual contact surfaces of the upper cushion block 2 and the lower cushion block 3 are inclined surfaces, the height of the lower cushion block 3 near the edge of the groove base 1 is higher, and two fixing bolts are set through the edge of the groove base 1 4 respectively connect the upper cushion block 2 and the lower cushion block 3; there is a reserved gap between the two sets of sliding gaskets.

[0018] The contact surface between the upper block 2 and the machine tool has anti-slip lines.

[0019] The bottom of the groove base 1 has anti-skid lines.

[0020...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com