A non-contact brush seal and its manufacturing method

A technology of brush seal and manufacturing method, which is applied in the direction of leakage prevention, engine components, machines/engines, etc. It can solve the problems of permanent wear, unadjustable seal gap, and increased leakage, so as to ensure the sealing effect and improve the manufacturing Process, the effect of reducing frictional vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following describes the present invention in detail with reference to the drawings and specific embodiments.

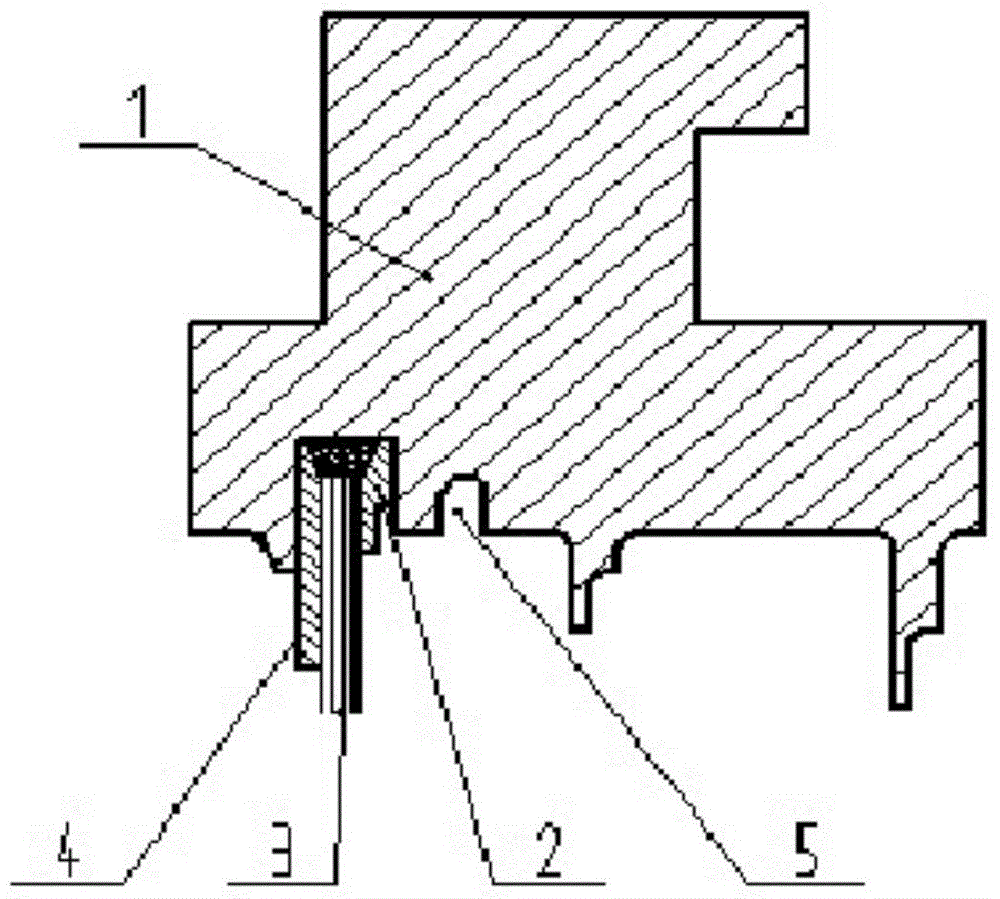

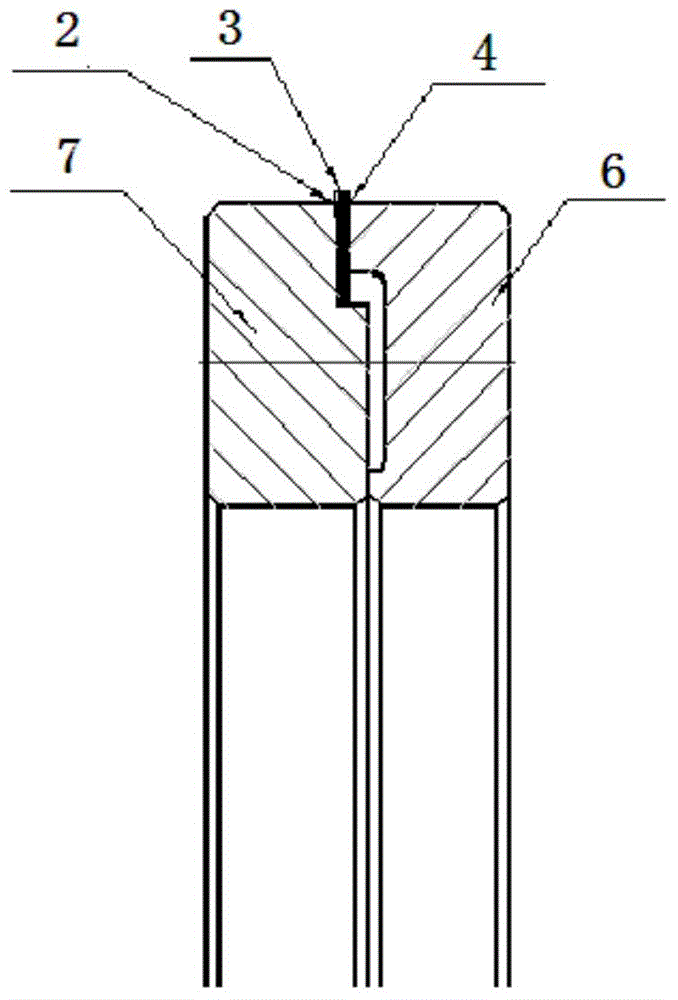

[0031] Combine figure 1 , The non-contact brush seal of the present invention includes a steam seal ring 1, a front baffle 2 and a rear baffle 4 arranged on the air seal ring 1, the front baffle 2, the brush wire 3 and the rear baffle 4 The front baffle 2 is assembled and welded into one body, and the front baffle 2 is located on the air inlet side. It is assembled with the steam seal ring 1 by riveting with the installation groove on the steam seal ring 1, and also includes a U-shaped riveting groove 5, which Located on the air intake side, the brush wires 3 are at an angle of 45° along the rotor rotation direction, and the brush wires 3 are arranged at an angle along the rotor rotation direction, which can reduce frictional vibration and have a small impact on the safety of the unit. The brush type steam seal is retrofitted Generally, it is a high-tooth modi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com