A tension leg platform

A tension leg platform and tension leg technology, applied in the direction of floating buildings, etc., can solve the problems of complex construction and increased structural weight, and achieve the effects of ensuring movement performance, improving redundancy, and large restoring force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the drawings, but the present invention is not limited to the following embodiments.

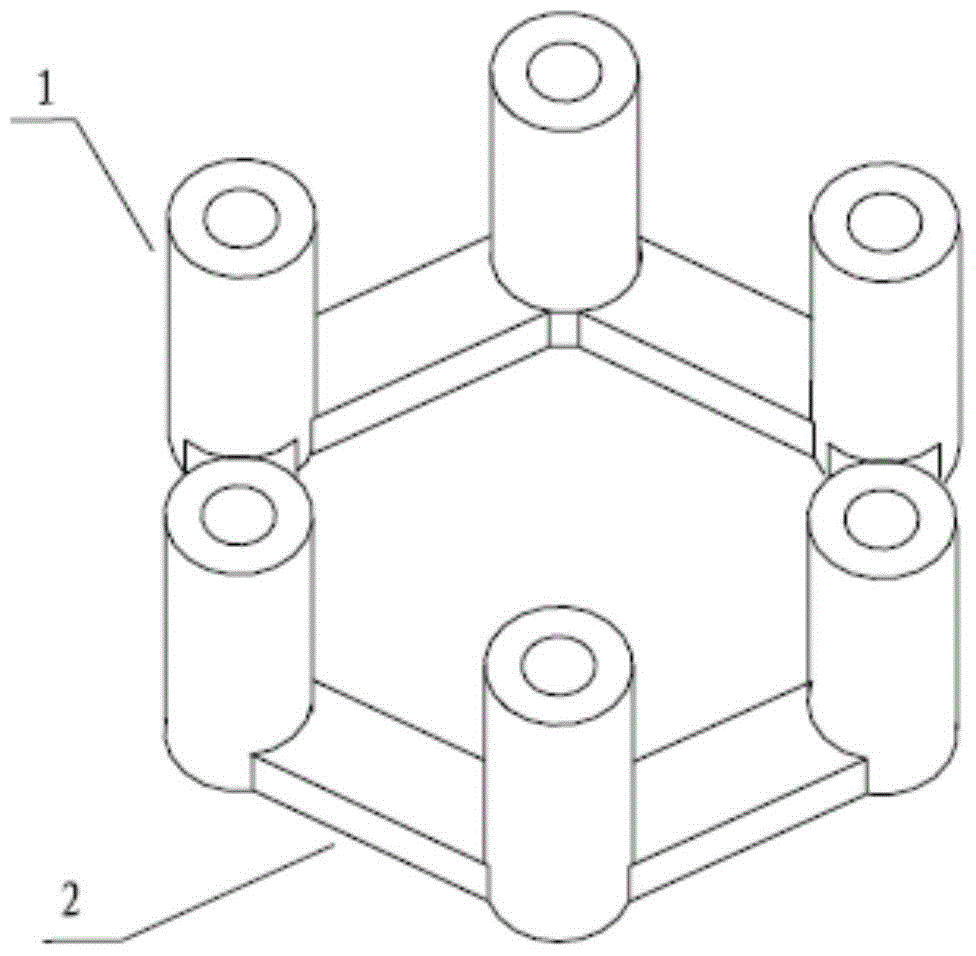

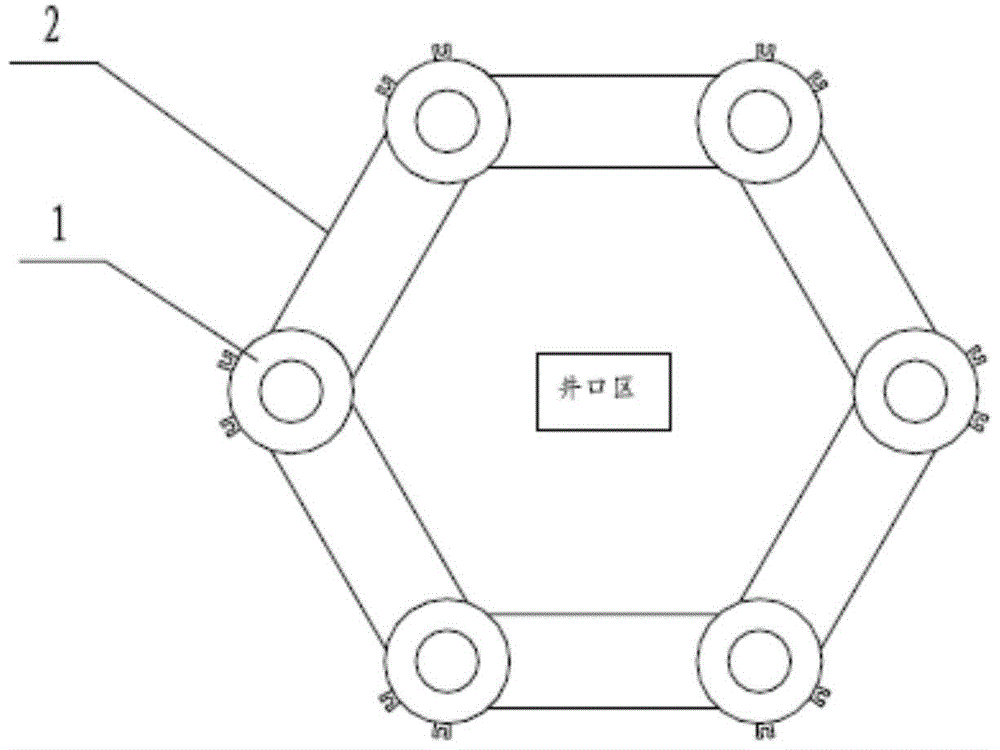

[0031] Such as 1 and figure 2 As shown, the present invention provides a six-pillar tension leg platform. The platform includes six pillars 1 and six pontoons 2, wherein the pillars 1 are cylindrical and the pontoons 2 are cuboid-shaped. The head and tail of the pontoon 2 are connected with one end of the column 1 to form a hexagonal ring structure. The increase in the number of columns and pontoons expands the main dimensions of the platform, provides more buoyancy, while reducing the remaining buoyancy, making the platform's draft shallower and waterline larger, and improving the stability of the platform.

[0032] Such as Figure 5 with Image 6 As shown, the bottom of each pontoon 2 is connected to two tension legs 3, which are connected to the seabed foundation. Due to the enlargement of the main dimension, ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com