Catalytic cracking catalyst capable of increasing yield of gasoline rich in isoalkane

A technology for catalytic cracking and isoparaffins, applied in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., to achieve the effects of improving composition, promoting isomerization reaction, and easy compounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] SAPO-11 molecular sieve is used, which is recorded as 1# additive.

Embodiment 2

[0034] Weigh 10g SAPO-11 molecular sieve, and measure 100mL of citric acid solution as a treatment agent. Add the SAPO-11 molecular sieve and the treatment agent into the round bottom flask in sequence, and place it at 40°C and stir at a constant speed. After reacting for 30 minutes, the stirring was stopped, and the product in the flask was suction-filtered, washed, dried at 100°C for 6 hours, and then calcined at 550°C to obtain the auxiliary agent.

[0035] The concentration of the citric acid solution used in this example is 0.1mol / L, 0.25mol / L, 0.5mol / L, 0.75mol / L and 1.0mol / L respectively, the auxiliary The additives are sequentially recorded as 2# auxiliary agent, 3# auxiliary agent, 4# auxiliary agent, 5# auxiliary agent and 6# auxiliary agent.

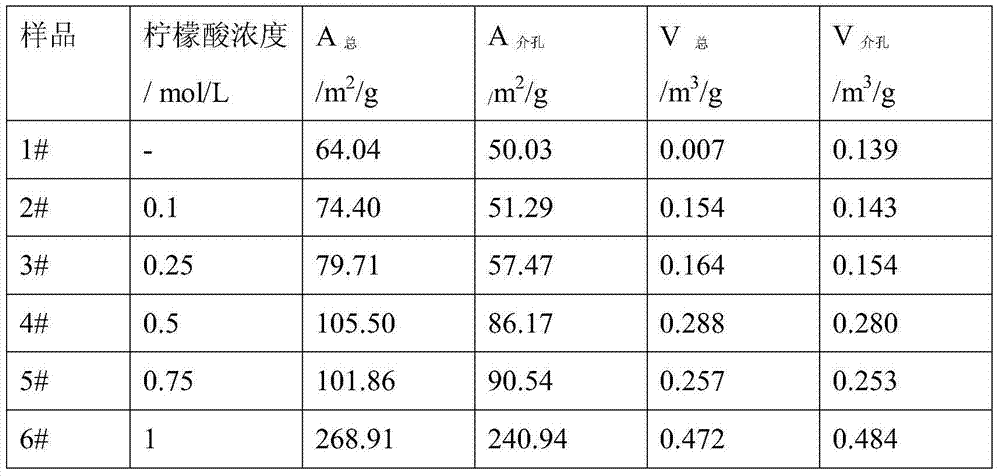

[0036] See Table 1 for the pore structure properties of the additives prepared by treating Example 1 and Example 2 with different concentrations of citric acid.

[0037] Table 1 Pore structure properties of meso-SAPO-11 prep...

Embodiment 3

[0040] Weigh 10 g SAPO-11 molecular sieve, and measure 100 mL of 0.5 mol / L citric acid treatment agent. Add the SAPO-11 molecular sieve and treatment agent into the round bottom flask in turn, heat and stir at a constant speed. After reacting for 30 minutes, the stirring was stopped, and the product in the flask was suction-filtered, washed, dried at 100°C for 6 hours, and then calcined at 550°C to obtain the auxiliary agent.

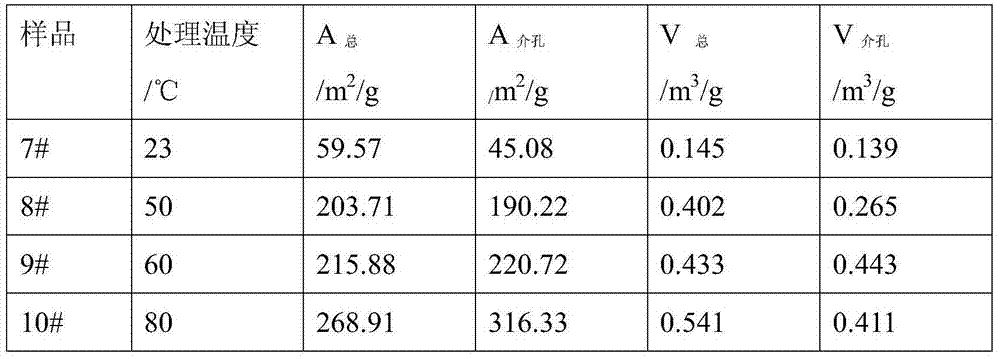

[0041] The heating temperatures used in this example are 23°C, 60°C, 80°C and 100°C respectively, and the prepared 2 additives are respectively recorded as 7# auxiliary agent, 8# auxiliary agent, 9# auxiliary agent and 10# auxiliary agent. The pore structure performance of each additive is shown in Table 2.

[0042] Table 2 Pore structure properties of meso-SAPO-11 prepared at different citric acid treatment temperatures

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com